In automotive applications, a cage in a bearing is a crucial component that maintains the separation and spacing of rolling elements such as balls or rollers. This cage, often made from materials like steel, brass, or synthetic polymers, ensures that the bearing operates smoothly by preventing contact and friction between individual rolling elements. Bearings with cages are typically found in wheel hubs, transmissions, and engines, where they enhance durability and efficiency. The cage's design directly impacts the bearing's performance by reducing heat generation and minimizing wear. For instance, a stamped steel cage is common in high-speed automotive bearings due to its strength and lightweight nature. Data from automotive manufacturers indicates that the use of optimized cage materials can extend bearing life by up to 30%, improving vehicle reliability and maintenance intervals.

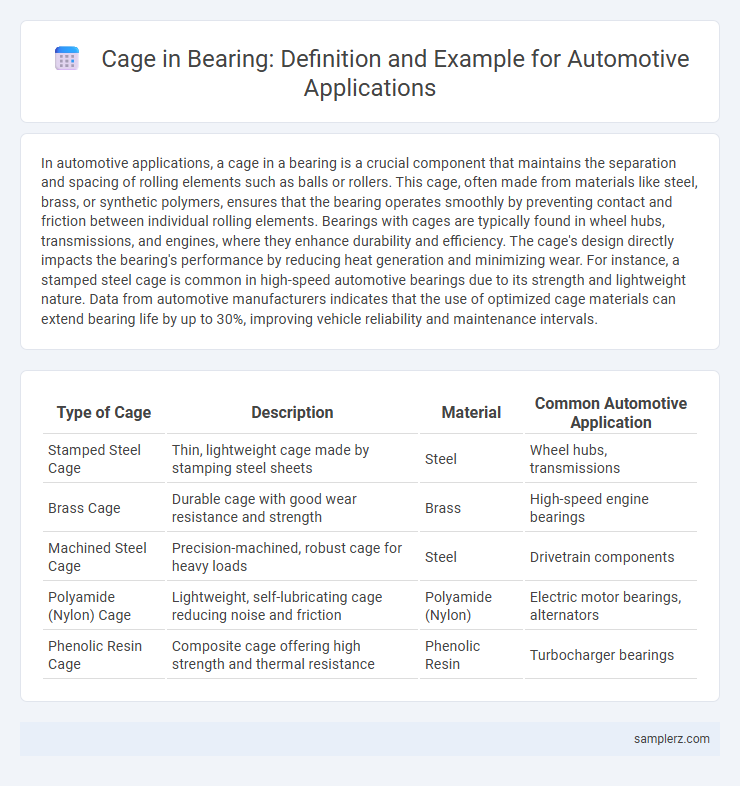

Table of Comparison

| Type of Cage | Description | Material | Common Automotive Application |

|---|---|---|---|

| Stamped Steel Cage | Thin, lightweight cage made by stamping steel sheets | Steel | Wheel hubs, transmissions |

| Brass Cage | Durable cage with good wear resistance and strength | Brass | High-speed engine bearings |

| Machined Steel Cage | Precision-machined, robust cage for heavy loads | Steel | Drivetrain components |

| Polyamide (Nylon) Cage | Lightweight, self-lubricating cage reducing noise and friction | Polyamide (Nylon) | Electric motor bearings, alternators |

| Phenolic Resin Cage | Composite cage offering high strength and thermal resistance | Phenolic Resin | Turbocharger bearings |

Introduction to Bearing Cages in Automotive Applications

Bearing cages in automotive applications serve as critical components that maintain the separation and alignment of rolling elements such as balls or rollers within the bearing assembly. These cages enhance the bearing's durability and performance by reducing friction, wear, and heat generation, which is essential for high-speed engine and transmission operations. Common materials for automotive bearing cages include stamped steel, brass, and polymer composites, chosen for their strength, resistance to corrosion, and ability to withstand harsh operating conditions.

Functions of Cages in Automotive Bearings

Cages in automotive bearings maintain precise spacing between rolling elements, ensuring uniform load distribution and minimizing friction during high-speed engine operations. They prevent contact between balls or rollers, reducing wear and extending bearing lifespan in critical components like wheel hubs and transmissions. By stabilizing rolling elements, cages enhance vehicle performance, reliability, and safety under varying driving conditions.

Common Materials Used for Bearing Cages

Bearing cages in automotive applications commonly utilize materials such as brass, stainless steel, and polymer composites to ensure durability and corrosion resistance under varying temperature and load conditions. Brass cages offer excellent strength and thermal conductivity, making them ideal for high-speed engine components, while stainless steel cages provide superior fatigue resistance and longevity in harsh environments. Polymer composite cages, often made from reinforced nylon or PTFE, deliver lightweight performance and reduced friction, contributing to enhanced fuel efficiency and quieter operation in modern vehicles.

Steel Cages: Features and Automotive Uses

Steel cages in automotive bearings offer exceptional strength and durability, ensuring reliable performance under high loads and extreme temperatures. Their resistance to corrosion and wear makes them ideal for critical components such as wheel hubs, transmissions, and differentials. Steel cages enhance the longevity and efficiency of bearings, contributing to overall vehicle safety and maintenance reduction.

Brass Cages: Advantages in Automotive Bearings

Brass cages in automotive bearings offer exceptional durability and resistance to high temperatures, making them ideal for engine and transmission components. Their excellent wear resistance enhances bearing lifespan under severe operating conditions, such as heavy loads and contamination. These properties contribute to improved reliability and performance in critical automotive applications.

Polyamide (Nylon) Cages in Automotive Systems

Polyamide (Nylon) cages in automotive bearings provide excellent wear resistance and lightweight properties essential for engine and transmission components. Their high chemical stability ensures reliable performance under varying temperatures and exposure to lubricants. This makes them a preferred choice for improving fuel efficiency and reducing noise in modern vehicle systems.

Phenolic Resin Cages for High-Speed Applications

Phenolic resin cages are widely used in high-speed automotive bearings due to their superior strength-to-weight ratio and excellent thermal stability. These cages reduce friction and wear, enabling smoother rotation at high speeds while maintaining dimensional accuracy under extreme conditions. Their resistance to corrosion and chemical degradation ensures long-lasting performance in demanding engine and transmission environments.

Cage Design Variations in Automotive Bearings

Cage design variations in automotive bearings include stamped steel, molded polymer, and machined brass types, each tailored to optimize durability, noise reduction, and friction performance under diverse operating conditions. Stamped steel cages provide high strength and heat resistance, making them suitable for high-speed engine applications, while polymer cages reduce weight and enhance corrosion resistance, ideal for electric vehicle motors. Machined brass cages offer precise dimensional control and excellent wear resistance, frequently used in heavy-duty transmission systems to maintain consistent bearing alignment.

Cage Failure Modes and Their Impact on Automotive Performance

Cage failure modes in automotive bearings include wear, fracture, and corrosion, which can lead to increased friction and overheating. These failures compromise bearing stability, causing noise, vibration, and premature component wear. Addressing cage issues ensures optimal bearing performance, enhancing vehicle reliability and safety.

Selecting the Right Cage Type for Automotive Bearings

Selecting the right cage type for automotive bearings involves evaluating operating conditions such as speed, load, and temperature to ensure optimal performance. Common cage materials include stamped steel for durability, polymer for lightweight and noise reduction, and machined brass for high load and corrosion resistance. Proper cage selection improves bearing lifespan, reduces friction, and enhances vehicle efficiency in automotive applications.

example of cage in bearing Infographic

samplerz.com

samplerz.com