A cotter pin is a simple but essential fastener commonly used in the automotive industry to secure other fasteners such as bolts and nuts. It is a metal pin with split ends that are bent after insertion to prevent loosening under vibration. This type of fastener is often found in securing wheel hubs, steering components, and suspension parts, where reliability and safety are critical. In automotive applications, cotter pins are typically made from stainless steel or carbon steel for corrosion resistance and strength. The design ensures that even under high stress or motion, components remain fastened securely, reducing the risk of mechanical failure. Cotter pins come in various sizes, selected based on the diameter of the hole and the load requirements of the specific vehicle part.

Table of Comparison

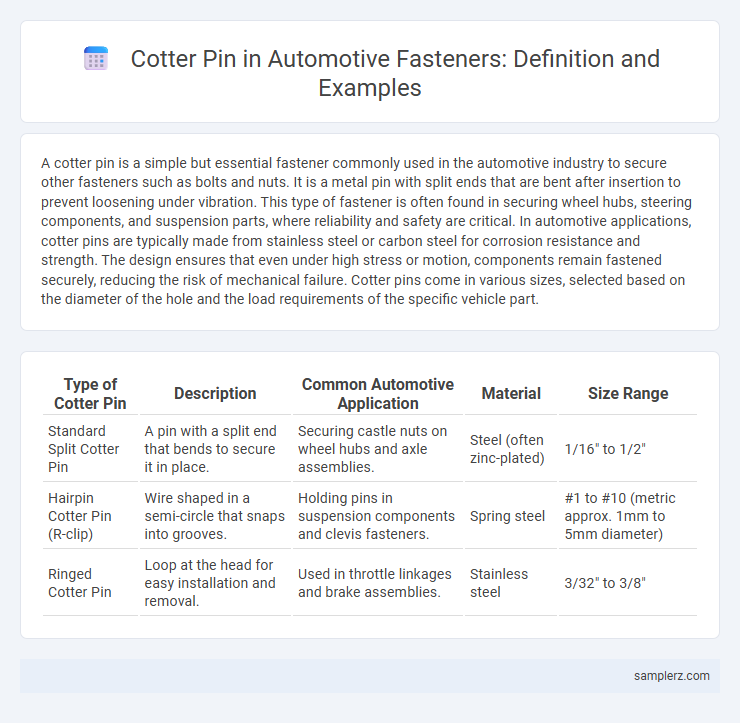

| Type of Cotter Pin | Description | Common Automotive Application | Material | Size Range |

|---|---|---|---|---|

| Standard Split Cotter Pin | A pin with a split end that bends to secure it in place. | Securing castle nuts on wheel hubs and axle assemblies. | Steel (often zinc-plated) | 1/16" to 1/2" |

| Hairpin Cotter Pin (R-clip) | Wire shaped in a semi-circle that snaps into grooves. | Holding pins in suspension components and clevis fasteners. | Spring steel | #1 to #10 (metric approx. 1mm to 5mm diameter) |

| Ringed Cotter Pin | Loop at the head for easy installation and removal. | Used in throttle linkages and brake assemblies. | Stainless steel | 3/32" to 3/8" |

Introduction to Cotter Pins in Automotive Fasteners

Cotter pins serve as essential automotive fasteners designed to secure nuts and bolts, preventing loosening due to vibration and torque. Commonly made from stainless steel or carbon steel, cotter pins are inserted through pre-drilled holes in shafts or bolts and then bent to lock components in place. Their application in wheel hubs, castle nuts, and steering linkages highlights their critical role in vehicle safety and reliability.

Common Applications of Cotter Pins in Vehicles

Cotter pins are commonly used in automotive fasteners to secure castle nuts on wheel hubs, preventing them from loosening under vibration. They also secure clevis pins in brake systems and steering linkages, ensuring critical components remain firmly connected during vehicle operation. These pins provide a simple yet effective locking mechanism essential for maintaining safety and stability in automotive assemblies.

Types of Cotter Pins Used in Automotive Assemblies

In automotive assemblies, commonly used types of cotter pins include the standard split cotter pin, hairpin cotter pin, and bowtie cotter pin, each designed for specific fastening applications. Split cotter pins secure castle nuts on axle shafts and steering components, while hairpin cotter pins provide quick-release fastening in brake linkages and throttle assemblies. Bowtie cotter pins offer higher resilience and are favored in suspension systems and heavy-duty engine mounts for their superior locking capability.

Role of Cotter Pins in Securing Wheel Hubs

Cotter pins play a crucial role in securing wheel hubs by locking castellated nuts in place, preventing loosening due to vibrations and rotational forces. Typically inserted through a nut and a drilled axle bolt, cotter pins maintain the integrity of wheel assembly under dynamic automotive conditions. Their reliability ensures safe vehicle operation by mitigating the risk of wheel detachment during motion.

Cotter Pins in Suspension and Steering Systems

Cotter pins are crucial fasteners in automotive suspension and steering systems, ensuring the secure locking of castle nuts on ball joints and tie rod ends. Their design prevents rotational loosening under vibrations and dynamic loads, maintaining alignment and safety in vehicle handling. These pins are typically made from high-strength steel to withstand harsh operating conditions and provide reliable performance throughout the lifespan of the suspension components.

Automotive Engine Components Utilizing Cotter Pins

Cotter pins are essential fasteners in automotive engine components such as securing castellated nuts on wheel hubs, connecting linkages in valve mechanisms, and locking components within the timing gear assembly. These pins provide reliable mechanical locking, preventing rotation and loosening under engine vibrations and dynamic loads. Their simplicity and effectiveness make cotter pins vital for maintaining engine integrity and ensuring safety in automotive applications.

Benefits of Using Cotter Pins in Car Fastening Solutions

Cotter pins enhance automotive fastening solutions by providing reliable locking mechanisms that prevent nuts and bolts from loosening due to vibration or dynamic loads. Their simple design allows for quick installation and removal, reducing maintenance time while ensuring safety in critical components like wheel assemblies and steering linkages. Resistant to corrosion and adaptable to various diameters, cotter pins maintain structural integrity under harsh engine and environmental conditions.

Maintenance and Replacement of Automotive Cotter Pins

Cotter pins in automotive applications frequently secure wheel nuts, castle nuts, and other critical fasteners to prevent loosening during operation. Regular maintenance involves inspecting cotter pins for signs of wear, corrosion, or deformation and replacing them immediately to ensure optimal safety and performance. Using high-quality stainless steel cotter pins during replacement enhances durability and resistance to environmental factors like moisture and road salt.

Safety Considerations for Cotter Pin Installation in Vehicles

Cotter pins in automotive fasteners play a crucial role in ensuring vehicle safety by preventing nuts and bolts from loosening under vibration. Proper installation requires selecting the correct size and material, typically stainless steel or brass, to withstand environmental stressors like corrosion and temperature fluctuations. Ensuring the pin is fully inserted and the ends are securely bent maintains structural integrity and prevents critical component failures during vehicle operation.

Innovations and Alternatives to Cotter Pins in Modern Automotives

Innovations in automotive fasteners have led to alternatives like locking wire, nylon-insert lock nuts, and castellated bolts replacing traditional cotter pins for enhanced security and ease of maintenance. Advanced materials such as stainless steel and titanium offer improved corrosion resistance and strength compared to conventional carbon steel cotter pins. These modern solutions increase vehicle reliability by minimizing loosening under high vibration and reducing assembly time in automotive manufacturing processes.

example of cotter pin in fastener Infographic

samplerz.com

samplerz.com