In automotive applications, a stanchion in a fork refers to the vertical tube or rod used in motorcycle front forks that supports the suspension system and allows smooth movement. The stanchion is typically made of hardened steel or aluminum, ensuring durability and resistance to wear under dynamic loads. Its precise machining and surface finish play a critical role in minimizing friction and maintaining effective fork performance over time. The stanchion works in conjunction with the fork slider, sealing components, and internal damping mechanisms to absorb shocks from road irregularities. High-quality stanchions can improve ride comfort, handling stability, and overall safety in motorcycles and other vehicles utilizing telescopic forks. Manufacturers often optimize stanchion dimensions, coatings, and materials to balance strength, weight, and corrosion resistance for different automotive fork designs.

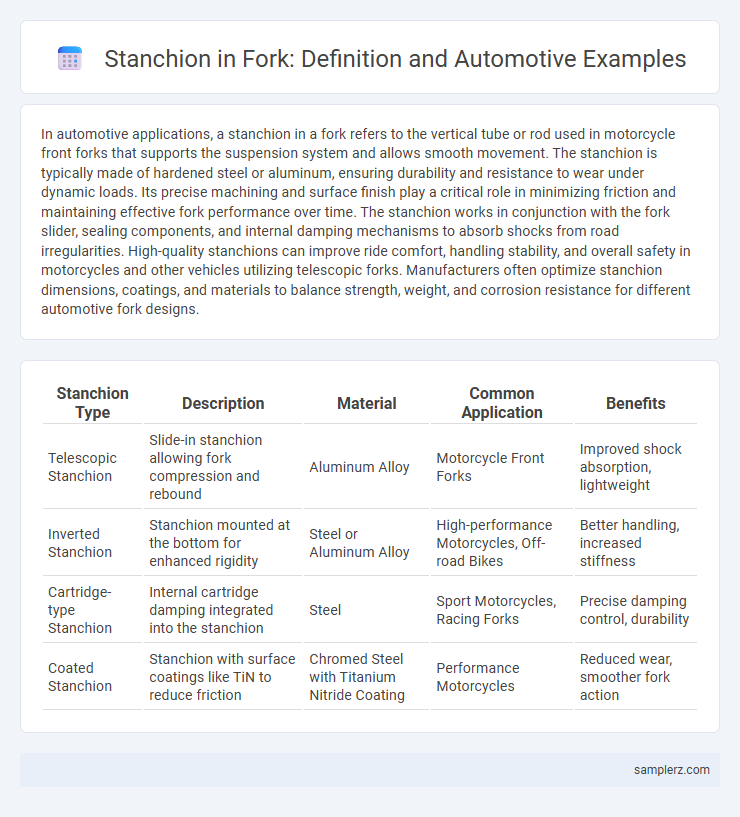

Table of Comparison

| Stanchion Type | Description | Material | Common Application | Benefits |

|---|---|---|---|---|

| Telescopic Stanchion | Slide-in stanchion allowing fork compression and rebound | Aluminum Alloy | Motorcycle Front Forks | Improved shock absorption, lightweight |

| Inverted Stanchion | Stanchion mounted at the bottom for enhanced rigidity | Steel or Aluminum Alloy | High-performance Motorcycles, Off-road Bikes | Better handling, increased stiffness |

| Cartridge-type Stanchion | Internal cartridge damping integrated into the stanchion | Steel | Sport Motorcycles, Racing Forks | Precise damping control, durability |

| Coated Stanchion | Stanchion with surface coatings like TiN to reduce friction | Chromed Steel with Titanium Nitride Coating | Performance Motorcycles | Reduced wear, smoother fork action |

Understanding Stanchions in Automotive Forks

Stanchions in automotive forks serve as the upper tubes that provide structural support and guide the suspension's movement, ensuring smooth and controlled travel over uneven surfaces. These precision-engineered components are typically made from high-strength steel or aluminum alloys to balance durability with weight reduction. Proper maintenance and material selection of stanchions enhance vehicle stability, shock absorption, and overall ride quality, critical factors in suspension system performance.

Key Functions of Fork Stanchions

Fork stanchions serve as the upper tubes in motorcycle suspension systems, providing structural support and guiding the fork's downward movement. They play a critical role in absorbing shocks from road irregularities, ensuring ride stability and comfort. Precision engineering of stanchions enhances durability and smooth suspension travel, directly impacting handling performance.

Common Materials Used for Fork Stanchions

Fork stanchions in automotive and motorcycle suspension systems are commonly made from materials such as high-strength steel, aluminum alloys, and sometimes titanium for premium applications due to their excellent balance of strength, durability, and weight. Chromed steel stanchions offer corrosion resistance and smooth surface finish for improved fork seal longevity. Aluminum stanchions provide reduced weight, enhancing vehicle handling and suspension responsiveness without compromising structural integrity.

Differences Between Inner and Outer Stanchions

Inner stanchions typically serve as the sliding components within the fork assembly, providing smooth suspension travel and absorbing road shocks, while outer stanchions act as the rigid structural elements that connect to the wheel and provide stability. Inner stanchions are often coated with materials like titanium nitride to reduce friction and increase durability, whereas outer stanchions are designed for maximum strength and resistance to bending under load. The distinctions in material composition and function between inner and outer stanchions play a crucial role in optimizing fork performance and rider control.

Role of Stanchions in Motorcycle Suspension

Stanchions in motorcycle forks serve as critical components that guide the suspension's movement, providing stability and absorption of shocks from uneven road surfaces. These cylindrical tubes slide within the fork's outer tubes, allowing smooth vertical motion while maintaining structural integrity and control during rides. High-quality stanchions made from materials like chrome-plated steel or titanium enhance durability, reduce friction, and improve overall suspension performance.

Maintenance Tips for Fork Stanchions

Regular inspection and cleaning of fork stanchions prevent dirt and debris buildup, which can cause seal damage and oil leakage, reducing suspension performance. Applying a high-quality fork-specific lubricant on stanchions ensures smooth fork travel and minimizes wear. Promptly replacing damaged seals and wipers extends the fork's lifespan and maintains consistent damping and rebound characteristics for optimal ride stability.

Signs of Wear in Fork Stanchions

Signs of wear in fork stanchions include visible scratches, pitting, and corrosion on the surface, which can compromise the fork's sealing and damping performance. Oil leaks around the seals often indicate worn or damaged stanchions, leading to decreased suspension efficiency and rider comfort. Regular inspection for dents or bends is crucial to maintain structural integrity and ensure optimal handling in automotive suspension systems.

Upgrading Fork Stanchion Performance

Upgrading fork stanchion performance involves using hardened, low-friction coatings like titanium nitride to reduce wear and improve smoothness in suspension travel. High-quality stanchions feature precision-ground surfaces and corrosion-resistant materials such as anodized aluminum to enhance durability and stiffness under load. Optimized stanchion designs contribute to better damping control, increased fork lifespan, and enhanced overall handling in motorcycles and mountain bikes.

Stanchion Damage: Causes and Prevention

Stanchion damage in motorcycle forks often results from improper maintenance, corrosion, or impact with debris while riding, compromising suspension performance and safety. Regular cleaning, use of protective fork gaiters, and timely replacement of fork oil significantly reduce wear and prevent scratches or dents on the stanchion tubes. Ensuring proper alignment and avoiding excessive loading further minimizes the risk of bending or damage to the fork stanchions.

Stanchion Innovations in Modern Fork Design

Stanchion innovations in modern fork design enhance suspension performance and durability by utilizing advanced materials like lightweight aluminum alloys and carbon fiber composites. Precision engineering improves stanchion smoothness and reduces friction, resulting in better shock absorption and rider control. Integration of sealed cartridge systems and coating technologies like titanium nitride further extends fork lifespan and resistance to wear.

example of stanchion in fork Infographic

samplerz.com

samplerz.com