A gantry in an automotive lift refers to the structural framework that supports the lifting mechanism used to raise vehicles for inspection and repair. These gantries are designed with heavy-duty steel components to ensure stability and safety while handling various vehicle weights. Data from leading manufacturers shows that gantries in automotive lifts can support loads ranging from 5,000 to over 20,000 pounds, catering to both passenger cars and commercial trucks. The entity of a gantry lift typically includes vertical columns, horizontal beams, and lifting arms, equipped with hydraulic or electric actuators for smooth elevation. Sensor data integrated into modern gantry lifts enhances precision by monitoring load distribution and balance during operation. Current market trends highlight the demand for gantry lifts with advanced control systems to improve efficiency and reduce maintenance downtime in automotive service centers.

Table of Comparison

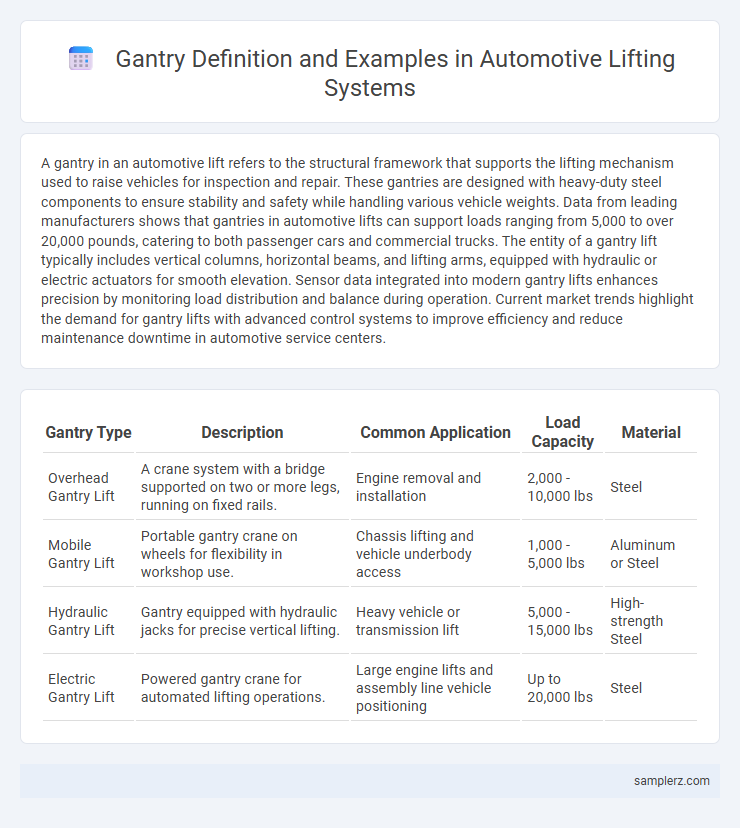

| Gantry Type | Description | Common Application | Load Capacity | Material |

|---|---|---|---|---|

| Overhead Gantry Lift | A crane system with a bridge supported on two or more legs, running on fixed rails. | Engine removal and installation | 2,000 - 10,000 lbs | Steel |

| Mobile Gantry Lift | Portable gantry crane on wheels for flexibility in workshop use. | Chassis lifting and vehicle underbody access | 1,000 - 5,000 lbs | Aluminum or Steel |

| Hydraulic Gantry Lift | Gantry equipped with hydraulic jacks for precise vertical lifting. | Heavy vehicle or transmission lift | 5,000 - 15,000 lbs | High-strength Steel |

| Electric Gantry Lift | Powered gantry crane for automated lifting operations. | Large engine lifts and assembly line vehicle positioning | Up to 20,000 lbs | Steel |

Understanding Gantry Systems in Automotive Lifting

Gantry systems in automotive lifting provide robust support for heavy vehicle components, enabling precise positioning and enhanced safety during maintenance or assembly. These structures consist of overhead beams and adjustable hoists that facilitate vertical and horizontal movement, optimizing workflow in garages and manufacturing plants. Incorporating gantry lifts can significantly improve efficiency in engine removal, transmission repairs, and chassis inspections by offering stable and versatile lifting solutions.

Key Components of a Gantry Lift

A gantry lift in automotive settings typically features key components such as a robust steel frame, adjustable lifting arms, and a high-capacity hydraulic pump system. Precision-engineered pulleys and heavy-duty cables enable smooth vertical motion, ensuring safety and stability during vehicle lifting. Integrated control panels with emergency stop functions enhance operational efficiency and user safety.

Types of Gantry Lifts Used in Automotive Workshops

Hydraulic gantry lifts dominate automotive workshops for their capacity to handle heavy vehicles with precise height adjustment, improving safety and workflow efficiency. Electric gantry lifts offer energy-efficient operation and quieter performance, making them ideal for indoor environments focused on noise reduction and environmental standards. Pneumatic gantry lifts provide fast lifting speeds and lower maintenance requirements, suitable for workshops requiring rapid vehicle servicing and minimal downtime.

How Gantry Lifts Improve Vehicle Maintenance

Gantry lifts provide enhanced access to a vehicle's underside, allowing mechanics to perform inspections and repairs more efficiently by elevating cars safely and steadily. Their robust design supports heavy vehicles, reducing the risk of accidents and improving workshop safety. Incorporating gantry lifts into automotive maintenance streamlines workflows, decreasing downtime and increasing overall productivity.

Example: Portable Gantry Lift for Car Repairs

A portable gantry lift for car repairs offers versatile support for lifting vehicles safely in various workshop environments, accommodating different car sizes up to 2 tons. These gantry lifts feature adjustable height settings and robust steel frames, ensuring stability and ease of mobility with heavy-duty caster wheels. Their design allows mechanics to perform undercarriage inspections, brake repairs, and suspension work efficiently without the need for permanent installation.

Safety Features in Automotive Gantry Lifts

Automotive gantry lifts are equipped with advanced safety features such as load sensors that prevent overloading and automatic locking mechanisms to secure vehicles during lifting. High-strength steel construction and reinforced support beams ensure structural integrity under heavy loads, reducing the risk of collapse. Integrated emergency stop controls and non-slip platforms further enhance operator safety by providing immediate lifting halt and stable working surfaces.

Gantry vs. Traditional Two-Post Lifts: A Comparison

Gantry lifts in automotive workshops offer enhanced stability and load distribution compared to traditional two-post lifts, utilizing overhead support beams to minimize vehicle sway during lifting. Their robust design allows for higher weight capacities and safer handling of heavy or unevenly distributed loads, reducing the risk of mechanical failure. In contrast, traditional two-post lifts rely on vertical posts only, which can result in increased stress on lifting arms and limitations in accommodating diverse vehicle sizes or shapes.

Installation Process for Automotive Gantry Lifts

The installation process for automotive gantry lifts requires precise anchoring of the gantry frame to a reinforced concrete floor, ensuring stability and safety during vehicle lifting operations. Technicians must align the hoist mechanism with the gantry beams and secure all hydraulic and electrical connections according to manufacturer specifications. Proper calibration and load testing follow, verifying the lift's maximum weight capacity and operational efficiency within automotive service bays.

Maintenance Tips for Gantry Lifting Systems

Regular inspection of gantry lifting systems is essential to identify wear on cables, pulleys, and hooks, preventing potential failures. Lubricate all moving parts according to manufacturer specifications to reduce friction and extend the lifespan of components. Ensure load limits are strictly followed and safety devices such as limit switches and emergency stop buttons are tested routinely for optimal performance and worker safety.

Choosing the Right Gantry Lift for Your Auto Shop

Selecting the right gantry lift for your auto shop involves evaluating weight capacity, mobility, and durability to ensure efficient vehicle handling and safety. Popular models like the 2-ton capacity Harbor Freight Gantry Crane or the versatile OTC 10,000 lb. Gantry Crane offer reliable performance for engine and transmission removal tasks. Prioritizing features such as adjustable height, heavy-duty steel construction, and secure casters can optimize workflow and increase productivity in automotive repair environments.

example of gantry in lift Infographic

samplerz.com

samplerz.com