A spool in a differential is a mechanical component that replaces the traditional differential gears, creating a solid connection between the axle shafts. This device ensures both wheels on an axle rotate at the same speed, eliminating the differentiation of power distribution typically provided by a conventional differential. Spools are commonly used in high-performance and racing vehicles to maximize traction and improve acceleration on straight paths. Spools are typically made from robust steel or aluminum alloys to withstand the extreme forces experienced during aggressive driving. Compared to limited-slip or open differentials, spools provide a simpler, more durable design but reduce maneuverability during turns, as both wheels must spin at the same rate. Automotive enthusiasts and track racers often choose spools to enhance power delivery and traction on tracks where cornering dynamics are less critical.

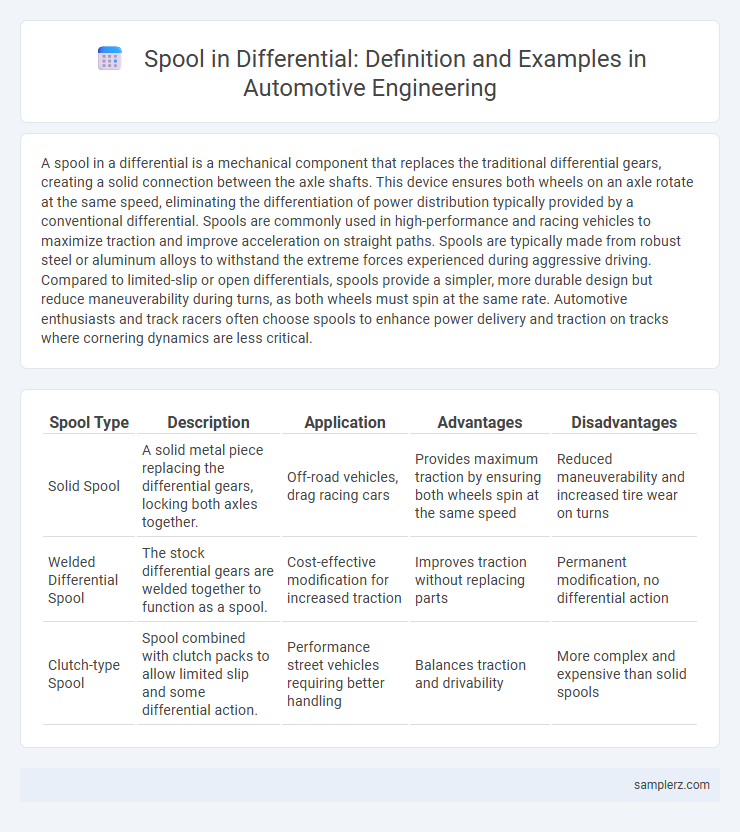

Table of Comparison

| Spool Type | Description | Application | Advantages | Disadvantages |

|---|---|---|---|---|

| Solid Spool | A solid metal piece replacing the differential gears, locking both axles together. | Off-road vehicles, drag racing cars | Provides maximum traction by ensuring both wheels spin at the same speed | Reduced maneuverability and increased tire wear on turns |

| Welded Differential Spool | The stock differential gears are welded together to function as a spool. | Cost-effective modification for increased traction | Improves traction without replacing parts | Permanent modification, no differential action |

| Clutch-type Spool | Spool combined with clutch packs to allow limited slip and some differential action. | Performance street vehicles requiring better handling | Balances traction and drivability | More complex and expensive than solid spools |

Understanding Differential Spool: An Overview

A differential spool replaces the traditional differential gear set with a solid connection, forcing both wheels on an axle to rotate at the same speed. This setup enhances traction in off-road and racing applications by eliminating wheel slip, but it can cause handling challenges on turns due to the lack of wheel speed differentiation. Performance vehicles and modified off-road trucks commonly use differential spools to maximize power delivery and improve stability on uneven terrain.

What Is a Spool in Automotive Differentials?

A spool in automotive differentials is a solid metal component that locks both wheels on an axle together, causing them to rotate at the same speed without allowing any differential action. Commonly used in high-performance or off-road vehicles, spools replace the standard differential gears to maximize traction by eliminating wheel slip during acceleration. By providing a fixed connection between the axle shafts, spools improve power transfer to the ground but can reduce maneuverability during tight turns.

How a Differential Spool Differs from Other Locking Devices

A differential spool is a solid coupling that locks both wheels on an axle together, forcing them to rotate at the same speed, unlike limited-slip differentials that allow some differentiation. This design eliminates the gear mechanism found in other locking devices such as clutch packs or helical gears, resulting in a simpler, more robust unit often used in drag racing and off-road applications. Spools provide direct power transfer with no slip, improving traction but reducing maneuverability compared to other locking differentials.

Common Applications of Spools in Performance Vehicles

Spools are commonly used in performance vehicles to enhance traction by locking the differential, ensuring both wheels rotate at the same speed regardless of road conditions. This modification is prevalent in drag racing, off-road vehicles, and drift cars where maximum power transfer and controlled wheel spin are critical. By eliminating differential action, spools improve acceleration and handling on slippery or uneven surfaces, making them essential in high-performance drivetrain setups.

Example Scenarios: Spools in Off-Road and Drag Racing Cars

Spools in differentials lock both wheels on an axle to rotate at the same speed, providing maximum traction in off-road vehicles navigating uneven terrain and drag racing cars requiring precise power delivery for rapid acceleration. Off-road trucks benefit from spools by maintaining consistent wheel rotation when traversing rocky or muddy trails, preventing wheel slip and enhancing stability. In drag racing, spools enable optimal power transfer to the ground, improving launch and quarter-mile times by eliminating differential slip during hard acceleration.

Key Benefits of Using a Spool in a Differential

A spool in a differential locks both axle shafts together, ensuring equal power distribution to each wheel, which improves traction in high-performance and off-road vehicles. This setup eliminates the risk of wheel slip during acceleration by preventing the differential action from allowing one wheel to spin freely. Enhanced durability and simplified design reduce maintenance needs, making spools a reliable choice for racing and heavy-duty applications.

Drawbacks and Potential Issues with Differential Spools

Differential spools eliminate the differential action by locking both wheels on an axle to rotate at the same speed, which can cause poor handling and increased tire wear during turns. This lack of differentiation leads to drivetrain binding and stress on axles and suspension components, potentially resulting in premature mechanical failure. Vehicles equipped with differential spools may also experience reduced traction on uneven surfaces, limiting their overall performance and safety.

Spool Installation: What to Consider for Your Vehicle

Spool installation in a differential replaces the traditional limited-slip or locking mechanism with a solid connection, providing 100% torque transfer between wheels for maximum traction. When installing a spool, consider the vehicle's intended use, as it can cause increased tire wear and make turning more difficult on pavement due to the lack of differential action. Proper alignment and ensuring compatibility with the axle housing and gearing are critical for optimal performance and durability in off-road or high-performance automotive applications.

Spool vs Limited Slip Differential: A Comparative Example

A spool in a differential permanently locks both wheels on an axle together, ensuring they rotate at the same speed for maximum traction in racing or off-road scenarios. In contrast, a limited slip differential (LSD) allows for some difference in wheel speed, improving cornering performance by reducing wheel hop and tire wear. Comparing these, a spool offers superior straight-line traction but sacrifices drivability, while an LSD balances traction and handling under varied driving conditions.

Real-World Performance Gains Using Spools in Differentials

Using spools in differentials significantly enhances traction by locking both wheels together, which improves power delivery in high-torque scenarios such as drag racing or off-road driving. This mechanical locking mechanism eliminates wheel slip, providing consistent power transfer and better acceleration on low-grip surfaces. Real-world performance gains include improved launch control and enhanced stability during aggressive cornering, making spools a popular choice for performance vehicles and dedicated race cars.

example of spool in differential Infographic

samplerz.com

samplerz.com