A dimple in a piston refers to a small, intentional indentation on the piston crown designed to improve combustion efficiency. This feature is commonly used in automotive engines to promote better air-fuel mixture turbulence, resulting in more complete combustion. The dimple's shape and placement are engineered based on the engine's specifications and fuel type. Pistons with dimples help reduce the risk of engine knocking by controlling combustion temperature and flame propagation. This design is particularly useful in high-performance and turbocharged engines where precise combustion control is critical. Data shows that pistons with optimized dimples can enhance engine power output and fuel economy while lowering emissions.

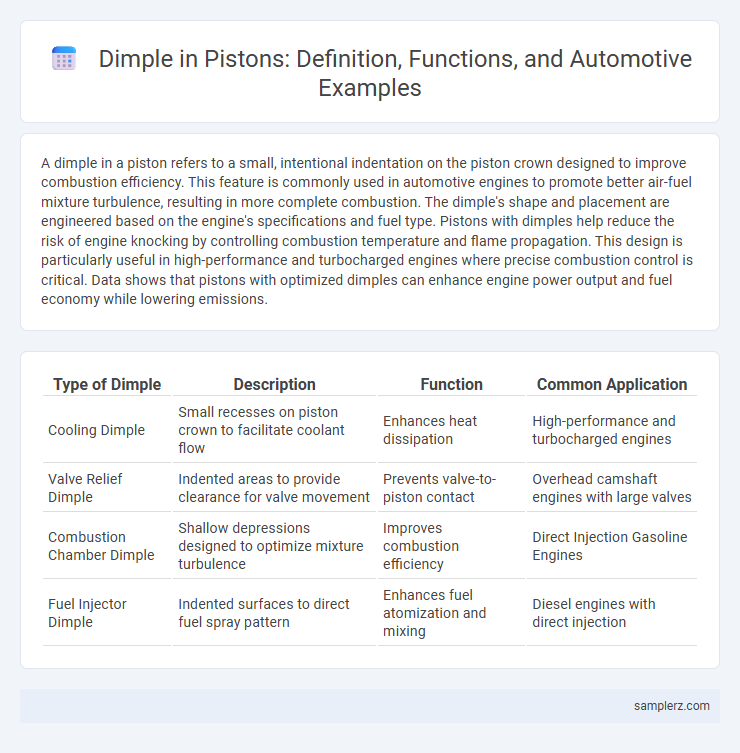

Table of Comparison

| Type of Dimple | Description | Function | Common Application |

|---|---|---|---|

| Cooling Dimple | Small recesses on piston crown to facilitate coolant flow | Enhances heat dissipation | High-performance and turbocharged engines |

| Valve Relief Dimple | Indented areas to provide clearance for valve movement | Prevents valve-to-piston contact | Overhead camshaft engines with large valves |

| Combustion Chamber Dimple | Shallow depressions designed to optimize mixture turbulence | Improves combustion efficiency | Direct Injection Gasoline Engines |

| Fuel Injector Dimple | Indented surfaces to direct fuel spray pattern | Enhances fuel atomization and mixing | Diesel engines with direct injection |

Understanding Dimples in Pistons: An Overview

Dimples in pistons are small, shallow indentations on the piston crown designed to improve combustion efficiency by enhancing air-fuel mixture turbulence. These dimples promote better flame propagation and reduce the tendency for engine knocking, contributing to smoother engine performance and increased power output. Understanding the role of piston dimples is essential for optimizing engine design and achieving higher fuel efficiency in automotive applications.

How Dimple Designs Influence Piston Performance

Dimple designs on pistons optimize combustion efficiency by enhancing air-fuel mixture turbulence, leading to more complete and faster burning. These indentations reduce weight while maintaining structural integrity, improving engine responsiveness and fuel economy. Advanced dimple geometries also minimize heat loss and control thermal expansion, boosting overall piston durability and performance.

Common Applications of Dimples in Automotive Pistons

Dimples in automotive pistons are commonly used to enhance fuel-air mixture turbulence, which improves combustion efficiency and reduces emissions. These indentations, strategically placed on the piston crown, facilitate better flame propagation and lower the risk of knocking. Such design features are prevalent in high-performance engines and modern fuel-injected systems to optimize power output and fuel economy.

Comparative Analysis: Traditional vs Dimpled Pistons

Dimpled pistons exhibit enhanced thermal management and reduced weight compared to traditional flat-surface pistons, resulting in improved combustion efficiency and durability. The dimples increase surface area, promoting better oil retention and lubrication, which decreases friction and wear during engine operation. In contrast, traditional pistons often face higher thermal stress and less efficient heat dissipation, leading to potential performance limitations in high-demand automotive engines.

Benefits of Utilizing Dimples in Piston Engineering

Dimples in piston surfaces enhance fuel atomization and combustion efficiency by creating micro-turbulence within the combustion chamber, leading to improved air-fuel mixture characteristics. This aerodynamic improvement reduces emissions, lowers fuel consumption, and increases overall engine performance. The strategic placement of dimples also aids in heat dissipation, preventing hotspots and extending piston lifespan in high-performance automotive engines.

Case Study: Dimples on High-Performance Engine Pistons

Dimples on high-performance engine pistons serve as critical design modifications that enhance combustion efficiency and reduce hotspot formation, exemplified by their application in racing engines like those developed by Mahle and JE Pistons. These shallow depressions optimize fuel-air mixture swirl and improve cooling by increasing the surface area, leading to enhanced thermal management under extreme operating conditions. Case studies demonstrate that dimples contribute to increased power output and durability, confirming their value in high-performance automotive engine design.

Manufacturing Processes for Dimpled Pistons

Dimpled pistons undergo precision manufacturing processes such as CNC machining and laser engraving to create uniform indentations that enhance oil retention and reduce friction. Advanced casting techniques combined with heat treatment ensure structural integrity and durability of the dimples under high thermal and mechanical stress. These manufacturing steps optimize piston performance by improving lubrication and reducing wear in internal combustion engines.

Impact of Dimple Placement on Combustion Efficiency

Precise dimple placement on a piston crown enhances combustion efficiency by promoting optimal air-fuel mixture swirl and turbulence, leading to faster and more complete combustion. Strategic positioning of dimples near the spark plug improves flame propagation, reducing knock and emissions while increasing power output. Computational fluid dynamics (CFD) analyses demonstrate that even slight adjustments to dimple geometry and location directly impact thermal efficiency and engine performance.

Real-World Examples of Dimpled Pistons in Modern Engines

Dimpled pistons are commonly found in high-performance automotive engines such as the Honda K20 and Mitsubishi 4G63, where their design improves combustion efficiency and reduces knock. These pistons feature precisely engineered depressions that promote better air-fuel mixing and enhance thermal management under extreme operating conditions. Real-world applications demonstrate significant gains in power output and fuel economy, making dimpled pistons a preferred choice in motorsport and performance tuning.

Future Trends in Dimple Technology for Pistons

Future trends in dimple technology for pistons emphasize advanced surface engineering techniques that enhance thermal management and reduce friction within the combustion chamber. Innovations include precision laser etching and micro-machining processes to create optimized dimple patterns, improving fuel efficiency and engine durability. Integration of AI-driven design simulations accelerates the development of custom dimple geometries tailored for electric and hybrid powertrain applications.

example of dimple in piston Infographic

samplerz.com

samplerz.com