A slap in the piston occurs when the piston moves laterally inside the cylinder bore, causing it to hit the cylinder wall. This phenomenon typically results from excessive piston-to-wall clearance due to wear or thermal expansion changes. Engine knock, reduced compression, and increased oil consumption are common symptoms linked to piston slap. Manufacturers address piston slap by using tighter tolerances in piston design and selecting materials with suitable thermal expansion rates. Modern engines often include coated pistons or cylinder liners to reduce friction and wear. Early detection of piston slap can prevent severe engine damage and maintain performance standards.

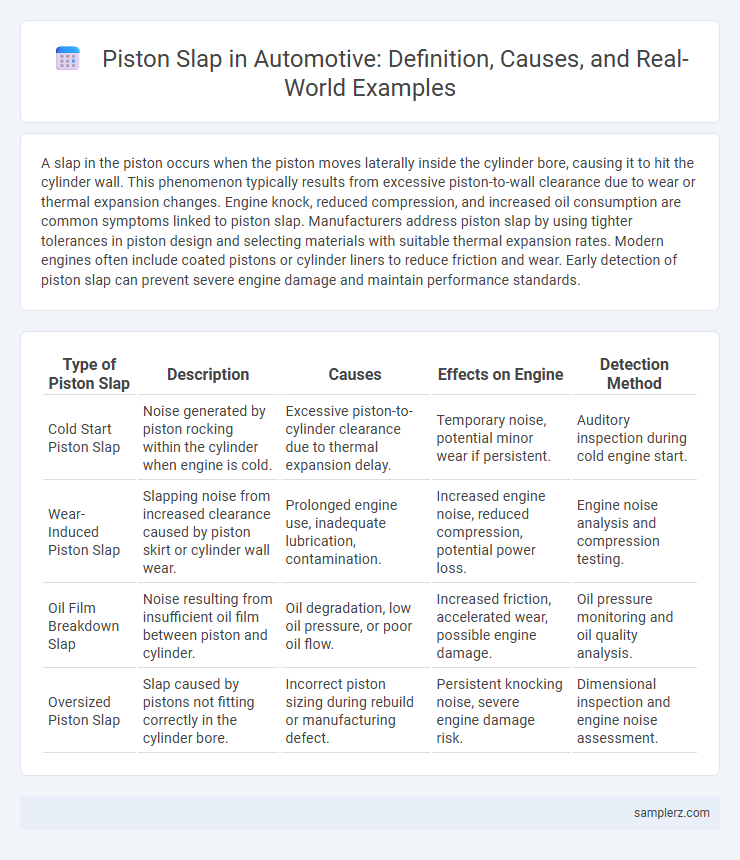

Table of Comparison

| Type of Piston Slap | Description | Causes | Effects on Engine | Detection Method |

|---|---|---|---|---|

| Cold Start Piston Slap | Noise generated by piston rocking within the cylinder when engine is cold. | Excessive piston-to-cylinder clearance due to thermal expansion delay. | Temporary noise, potential minor wear if persistent. | Auditory inspection during cold engine start. |

| Wear-Induced Piston Slap | Slapping noise from increased clearance caused by piston skirt or cylinder wall wear. | Prolonged engine use, inadequate lubrication, contamination. | Increased engine noise, reduced compression, potential power loss. | Engine noise analysis and compression testing. |

| Oil Film Breakdown Slap | Noise resulting from insufficient oil film between piston and cylinder. | Oil degradation, low oil pressure, or poor oil flow. | Increased friction, accelerated wear, possible engine damage. | Oil pressure monitoring and oil quality analysis. |

| Oversized Piston Slap | Slap caused by pistons not fitting correctly in the cylinder bore. | Incorrect piston sizing during rebuild or manufacturing defect. | Persistent knocking noise, severe engine damage risk. | Dimensional inspection and engine noise assessment. |

Understanding Piston Slap in Automotive Engines

Piston slap occurs when the piston rocks inside the cylinder bore, causing a distinctive knocking noise due to excessive clearance between the piston skirt and cylinder wall. This phenomenon typically arises from cylinder wear, piston wear, or thermal expansion differences, affecting engine performance and longevity. Recognizing piston slap early through sound analysis and mechanical inspection helps prevent severe engine damage and costly repairs.

Common Causes of Piston Slap

Piston slap commonly occurs due to excessive clearance between the piston and cylinder wall, often caused by engine wear or improper machining during rebuilds. Worn piston skirts and cylinder bore imperfections exacerbate the noise by allowing the piston to rock side-to-side within the cylinder. Low oil pressure or degraded lubrication further increases piston movement, accelerating the wear on both piston and cylinder surfaces.

Typical Symptoms of Piston Slap

Piston slap typically manifests as a distinct rattling noise during cold engine start-up, which diminishes as the engine warms and components expand. Engine vibration may increase due to the loose piston fit within the cylinder bore, affecting overall performance and fuel efficiency. Excessive piston slap can lead to accelerated wear on the cylinder walls and piston skirts, potentially causing engine damage if not promptly addressed.

Piston Slap vs. Other Engine Noises

Piston slap occurs when the piston rocks side-to-side within the cylinder bore, producing a distinct knocking noise typically noticeable during cold starts or acceleration. Unlike rod knock, which results from worn connecting rod bearings and causes deep, rhythmic knocking, piston slap generates a sharper, lighter sound due to loose piston-to-wall clearance. Differentiating piston slap from valve clatter or main bearing noise requires analysis of when the noise appears and its acoustic signature during engine operation.

Examples of Piston Slap in Modern Vehicles

Piston slap occurs when the piston rocks sideways within the cylinder bore, causing a distinct knocking noise often heard during cold starts or sudden acceleration in modern vehicles. Common examples include older Honda Accord engines and some GM V6 models where piston clearance design leads to this phenomenon. Modern engine designs use tighter tolerances and improved materials to minimize piston slap, but it remains a diagnostic indicator in certain high-mileage or poorly lubricated engines.

Effects of Piston Slap on Engine Performance

Piston slap causes a knocking noise due to the piston rocking within the cylinder, leading to increased engine vibrations and reduced fuel efficiency. The excessive clearance results in uneven wear on the cylinder walls, compromising compression and causing power loss. Over time, this condition can lead to costly repairs and decreased engine longevity.

Diagnostic Techniques for Identifying Piston Slap

Piston slap can be diagnosed through a combination of auditory analysis using mechanics' stethoscopes and engine knock sensors that detect abnormal noises during cold starts. Visual inspection with borescopes allows for direct observation of piston-to-cylinder wall clearance, while oil analysis can reveal metallic particles indicative of excessive piston movement. Advanced diagnostic techniques like vibration analysis and thermal imaging further pinpoint piston slap by identifying irregular engine vibrations and localized overheating patterns.

Real-World Cases: Piston Slap in Popular Car Models

Piston slap commonly occurs in older Toyota Tacoma models, particularly those with high mileage engines, where the piston skirts wear against the cylinder walls creating a distinctive knocking sound. Ford F-150 trucks with 5.0L V8 engines have reported piston slap issues due to clearance tolerances during cold starts. Chevrolet Silverado classics also experience piston slap problems, especially under heavy load conditions, highlighting the impact of engine design on piston noise.

Preventive Measures to Avoid Piston Slap

Piston slap occurs when the piston rocks inside the cylinder bore, causing noise and potential engine damage. To prevent piston slap, use high-quality pistons with tight manufacturing tolerances and ensure proper cylinder bore sizing during engine assembly. Regular oil changes with the recommended viscosity help maintain optimal lubrication, reducing piston-to-wall clearance and minimizing slap risk.

Repair Solutions for Addressing Piston Slap

Repair solutions for addressing piston slap typically involve replacing worn pistons and cylinders to restore proper clearance and minimize noise. Precision machining of cylinder walls and installing high-quality piston rings can enhance the seal, reducing the risk of further piston slap. Engine reconditioning services often include balancing components and ensuring tolerances meet manufacturer specifications to prolong engine life and improve performance.

example of slap in piston Infographic

samplerz.com

samplerz.com