A pintle in a hitch serves as a robust coupling device commonly used in heavy-duty towing applications within the automotive industry. This metal hook-like component connects trailers to towing vehicles, ensuring a secure and flexible link. It is especially favored in off-road and industrial vehicle setups for its ability to handle significant loads and rough terrain. Pintle hitches consist of a pintle hook on the towing vehicle and a lunette ring attached to the trailer, creating a pivot point that improves maneuverability. The design accommodates larger weight capacities compared to standard ball hitches, making it ideal for construction, military, and agricultural vehicles. The durability and strength of pintle hitches support safe towing in demanding environments, emphasizing reliability in automotive towing solutions.

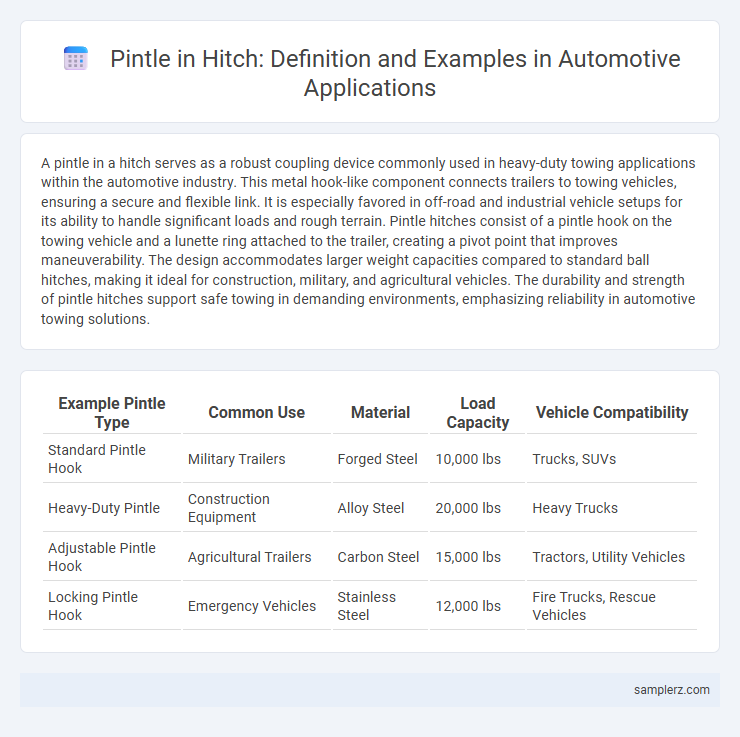

Table of Comparison

| Example Pintle Type | Common Use | Material | Load Capacity | Vehicle Compatibility |

|---|---|---|---|---|

| Standard Pintle Hook | Military Trailers | Forged Steel | 10,000 lbs | Trucks, SUVs |

| Heavy-Duty Pintle | Construction Equipment | Alloy Steel | 20,000 lbs | Heavy Trucks |

| Adjustable Pintle Hook | Agricultural Trailers | Carbon Steel | 15,000 lbs | Tractors, Utility Vehicles |

| Locking Pintle Hook | Emergency Vehicles | Stainless Steel | 12,000 lbs | Fire Trucks, Rescue Vehicles |

Introduction to Pintle Hitches in the Automotive Industry

Pintle hitches are heavy-duty towing devices commonly used in the automotive industry for attaching trailers to trucks and commercial vehicles. Featuring a hook and ring design, pintle hitches provide superior durability and flexibility, making them ideal for off-road, construction, and agricultural applications. Their robust construction supports high towing capacities, often exceeding 30,000 pounds, ensuring secure and reliable trailer connections.

Key Features of Pintle Hitches

Pintle hitches feature a robust hook-and-ring design that ensures superior towing strength and durability for heavy-duty applications. Their open hook mechanism allows for quick coupling and decoupling, making them ideal for off-road and agricultural vehicles. Constructed from high-grade steel with corrosion-resistant coatings, pintle hitches deliver reliable performance in harsh environments.

How Pintle Hitches Differ from Ball Hitches

Pintle hitches differ from ball hitches by offering a more secure and heavy-duty connection, ideal for towing heavy trailers or equipment. Unlike ball hitches, which use a spherical ball and socket mechanism, pintle hitches feature a hook and lunette ring design, allowing greater articulation and durability on rough terrains. This design makes pintle hitches preferred in military, agricultural, and industrial applications where maximum towing strength and flexibility are critical.

Typical Applications of Pintle Hitches

Pintle hitches are commonly used in heavy-duty towing applications such as military vehicles, agricultural equipment, and commercial trailers due to their robust design and high load capacity. They provide secure connections for transporting construction machinery, utility trailers, and large cargo in off-road or rugged environments. This type of hitch is favored for its durability and ability to accommodate misalignment during towing.

Example 1: Heavy-Duty Truck Pintle Hitch

Example 1: Heavy-Duty Truck Pintle Hitch features a robust steel construction designed to withstand maximum towing capacity often exceeding 30,000 pounds. Its pintle hook mechanism provides secure articulation for trailers used in construction, agriculture, and military applications. This type of hitch ensures reliability and flexibility in rugged environments, reducing trailer sway and enhancing overall safety during heavy hauling tasks.

Example 2: Military Vehicle Pintle Hitch

The Military Vehicle Pintle Hitch is designed for heavy-duty towing, offering robust connection and high load capacity ideal for rugged terrains. This pintle hitch example features a heavy-duty hook and lunette ring configuration, enabling secure coupling under extreme operational conditions. Its durability and strength make it essential for military logistics and equipment transport applications.

Example 3: Construction Equipment Pintle Hitch

Example 3: Construction equipment pintle hitches provide robust towing solutions for heavy-duty machinery such as bulldozers, excavators, and skid steers. These pintle hitches feature reinforced steel hooks and heavy-gauge mounting plates to withstand extreme stress and rough terrain conditions. Their design ensures secure, flexible coupling, enabling efficient transport of construction equipment over long distances.

Example 4: Agricultural Trailer Pintle Hitch

Example 4 of pintle hitches in the automotive sector is the agricultural trailer pintle hitch, designed for robust towing in farming operations. This hitch features a heavy-duty pintle hook and lunette ring, providing secure connections ideal for uneven terrains and heavy loads. Its durable steel construction ensures longevity and reliability when hauling equipment or trailers across agricultural fields.

Advantages of Using Pintle Hitches

Pintle hitches offer superior towing strength and durability, making them ideal for heavy-duty automotive applications and off-road vehicles. Their robust design allows for greater articulation and flexibility, reducing stress on the towing vehicle and trailer connection in uneven terrains. These advantages result in enhanced safety, reliability, and compatibility with a wide range of trailers and equipment.

Maintenance Tips for Pintle Hitches

Regularly inspect the pintle hitch for signs of wear, cracks, or rust to ensure optimal performance and safety. Lubricate the pintle hook and lunette ring with high-quality grease to prevent corrosion and reduce friction during towing. Tighten all bolts and fasteners to the manufacturer's specifications to avoid loosening under heavy loads and maintain secure connections.

example of pintle in hitch Infographic

samplerz.com

samplerz.com