Vapor lock in an automotive fuel system occurs when fuel vaporizes inside the fuel lines or carburetor, disrupting the continuity of liquid fuel flow to the engine. This phenomenon typically arises in older vehicles with carbureted engines and mechanical fuel pumps, especially under high temperature conditions or during extended idling. The vapor formation creates a blockage that prevents the fuel pump from delivering sufficient liquid fuel, causing engine stalling or difficulty starting. Heat sources near the fuel system, such as the exhaust manifold or engine block, can increase the fuel temperature and trigger vapor lock. Fuel volatility and inadequate fuel line insulation also contribute to the issue by facilitating premature vaporization. Modern automotive designs, including electronic fuel injection and in-tank electric pumps, have significantly reduced the incidence of vapor lock by maintaining fuel pressure and cooling the fuel system effectively.

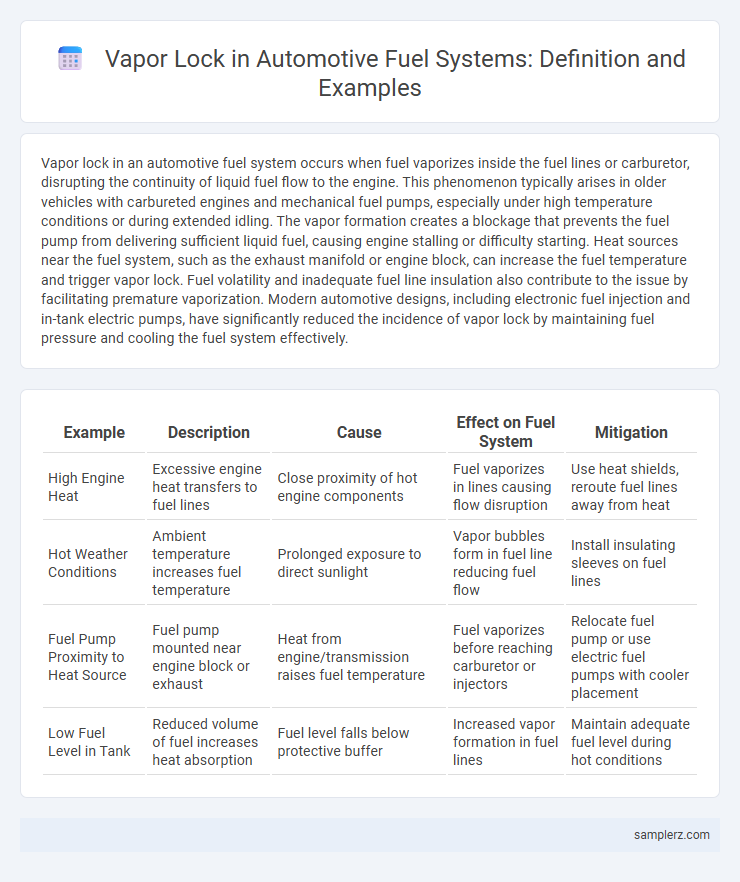

Table of Comparison

| Example | Description | Cause | Effect on Fuel System | Mitigation |

|---|---|---|---|---|

| High Engine Heat | Excessive engine heat transfers to fuel lines | Close proximity of hot engine components | Fuel vaporizes in lines causing flow disruption | Use heat shields, reroute fuel lines away from heat |

| Hot Weather Conditions | Ambient temperature increases fuel temperature | Prolonged exposure to direct sunlight | Vapor bubbles form in fuel line reducing fuel flow | Install insulating sleeves on fuel lines |

| Fuel Pump Proximity to Heat Source | Fuel pump mounted near engine block or exhaust | Heat from engine/transmission raises fuel temperature | Fuel vaporizes before reaching carburetor or injectors | Relocate fuel pump or use electric fuel pumps with cooler placement |

| Low Fuel Level in Tank | Reduced volume of fuel increases heat absorption | Fuel level falls below protective buffer | Increased vapor formation in fuel lines | Maintain adequate fuel level during hot conditions |

Understanding Vapor Lock in Automotive Fuel Systems

Vapor lock in automotive fuel systems occurs when fuel vaporizes prematurely due to excessive heat, causing a disruption in fuel flow to the engine. This phenomenon commonly affects carbureted engines, especially under high temperatures or during prolonged idling, leading to engine stalling or hesitation. Understanding vapor lock involves recognizing the critical role of fuel pump design, fuel line routing, and heat shielding in preventing vapor formation and maintaining consistent engine performance.

Common Causes of Vapor Lock in Vehicles

Vapor lock in automotive fuel systems commonly occurs due to excessive heat raising fuel temperature above its boiling point, causing vapor formation within fuel lines. High under-hood temperatures, especially in older carbureted engines or during hot weather conditions, contribute significantly to this issue. Additionally, low fuel pressure and prolonged idling exacerbate vapor lock by reducing fuel flow and increasing the likelihood of vapor pockets in the system.

Symptoms Indicating Vapor Lock Issues

Engine stalling and difficulty restarting, especially after short stops, often signal vapor lock in the fuel system. Noticeable loss of power during acceleration and erratic idling can indicate fuel vaporization disrupting fuel flow. Excessive heat around the fuel lines and carburetor area further confirms potential vapor lock problems.

How High Temperatures Trigger Vapor Lock

High temperatures in automotive engines cause the fuel in the fuel lines to vaporize, leading to vapor lock by obstructing fuel flow to the carburetor or fuel injectors. When ambient or engine heat exceeds the fuel's boiling point, especially in gasoline-powered vehicles, fuel vapor forms bubbles that block liquid fuel delivery, resulting in engine stalling or starting difficulties. Vapor lock frequently occurs in older carbureted systems or during hot weather conditions, emphasizing the importance of fuel system cooling and proper ventilation to prevent performance loss.

Real-World Examples of Vapor Lock in Cars

Vapor lock commonly occurs in older carbureted engines, especially in hot climates where high under-hood temperatures cause fuel to vaporize before reaching the engine, such as in classic muscle cars like the Ford Mustang or Chevrolet Camaro. Modern fuel-injected engines have largely mitigated this issue, but vintage vehicles or those with poorly maintained fuel systems still experience vapor lock during extreme heat or extended idling. Diesel engines typically avoid vapor lock due to higher fuel flash points, making the problem most prevalent in gasoline-powered vehicles operating under severe thermal stress.

Impact of Vapor Lock on Engine Performance

Vapor lock occurs when fuel vaporizes prematurely in the fuel system, disrupting the consistent flow of liquid fuel to the engine. This leads to engine stalling, hesitation, and reduced power output, severely impacting vehicle reliability and drivability. High ambient temperatures and fuel delivery system design are critical factors influencing vapor lock susceptibility in automotive engines.

Vapor Lock in Classic vs. Modern Automobiles

Vapor lock occurs when fuel vaporizes in the fuel line, causing engine stalling often seen in classic automobiles with carbureted fuel systems due to lower fuel pressure and lack of fuel injection technology. Modern automobiles utilize electronic fuel injection and higher pressure systems that significantly reduce the risk of vapor lock by maintaining fuel in liquid form even under high engine temperatures. The transition from mechanical fuel pumps to electric pumps and improved fuel rail cooling has enhanced fuel delivery reliability, minimizing vapor lock incidents in contemporary vehicles.

Preventative Measures Against Vapor Lock

Vapor lock in automotive fuel systems occurs when fuel vaporizes in the fuel lines, causing engine stalling or failure to start. Preventative measures include installing heat shields, using fuel lines with higher temperature resistance, and maintaining proper fuel pressure with an effective fuel pump. Employing fuel additives that increase the fuel's boiling point can also reduce the risk of vapor lock under extreme heat conditions.

Diagnosing Vapor Lock in Fuel Systems

Diagnosing vapor lock in fuel systems involves monitoring fuel temperature and pressure fluctuations within the fuel lines, especially under high ambient temperatures or prolonged engine idling. Technicians use fuel pressure gauges and infrared thermometers to identify abnormal vapor formation causing fuel delivery interruptions. Inspecting fuel pumps, checking for air leaks, and verifying the condition of fuel return lines help pinpoint vapor lock sources in modern automotive fuel systems.

Solutions and Fixes for Vapor Lock Problems

Vapor lock in automotive fuel systems can be resolved by installing heat shields around fuel lines and carburetors to reduce exposure to high engine temperatures. Upgrading to return-style fuel systems helps maintain consistent fuel pressure and prevents vapor formation. Fuel additives designed to raise the boiling point of gasoline and regular maintenance of fuel pumps and filters also mitigate vapor lock occurrences effectively.

example of vapor lock in fuel system Infographic

samplerz.com

samplerz.com