Stiction in automotive pistons occurs when the piston rings stick to the cylinder wall, causing resistance during engine operation. This phenomenon is often due to inadequate lubrication or the accumulation of carbon deposits on the cylinder surface. Stiction can lead to increased friction, reduced engine efficiency, and potential damage to the piston or cylinder components. Engine manufacturers monitor stiction levels to ensure proper piston movement and maintain engine performance. Diagnostic tools measure the resistance in piston travel to detect signs of stiction early. Addressing stiction involves using high-quality lubricants and performing regular engine maintenance to prevent deposit buildup and ensure smooth piston operation.

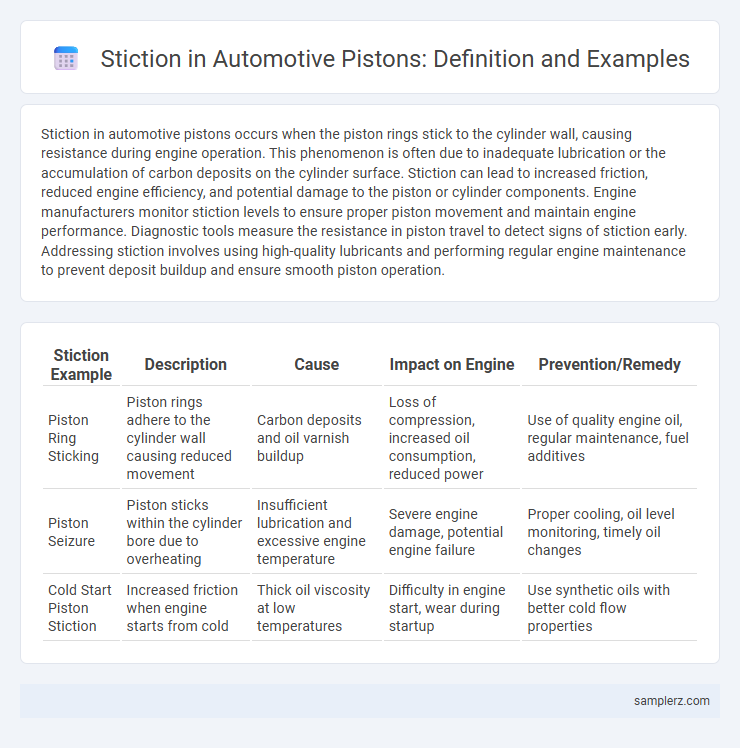

Table of Comparison

| Stiction Example | Description | Cause | Impact on Engine | Prevention/Remedy |

|---|---|---|---|---|

| Piston Ring Sticking | Piston rings adhere to the cylinder wall causing reduced movement | Carbon deposits and oil varnish buildup | Loss of compression, increased oil consumption, reduced power | Use of quality engine oil, regular maintenance, fuel additives |

| Piston Seizure | Piston sticks within the cylinder bore due to overheating | Insufficient lubrication and excessive engine temperature | Severe engine damage, potential engine failure | Proper cooling, oil level monitoring, timely oil changes |

| Cold Start Piston Stiction | Increased friction when engine starts from cold | Thick oil viscosity at low temperatures | Difficulty in engine start, wear during startup | Use synthetic oils with better cold flow properties |

Understanding Stiction in Automotive Pistons

Stiction in automotive pistons occurs when friction causes the piston to stick against the cylinder wall, impairing smooth engine operation and reducing fuel efficiency. This phenomenon often arises due to inadequate lubrication, carbon buildup, or worn piston rings, leading to increased wear and potential engine damage. Understanding stiction helps optimize engine design, improve lubrication systems, and enhance overall vehicle performance.

Causes of Stiction in Piston Assemblies

Stiction in piston assemblies commonly arises from inadequate lubrication, where oil film breakdown causes metal-to-metal contact, leading to increased friction and wear. Contaminants such as dirt or carbon deposits exacerbate this issue by creating abrasive surfaces that impede smooth piston movement. Furthermore, thermal expansion and corrosion can alter clearances, intensifying stiction and reducing engine efficiency.

Common Signs of Piston Stiction in Engines

Common signs of piston stiction in engines include uneven engine idling, reduced power output, and increased fuel consumption. Drivers may notice rough engine starts, persistent knocking sounds, and a significant decrease in overall engine performance. Regular maintenance and timely oil changes can help prevent the buildup of residues that contribute to piston stiction in automotive engines.

How Stiction Affects Piston Performance

Stiction in pistons occurs when friction between the piston rings and cylinder walls causes the piston to resist initial movement, leading to delayed engine response and uneven combustion. This phenomenon results in increased wear on the cylinder lining and reduced fuel efficiency due to incomplete sealing and compromised compression. Persistent stiction can cause engine knocking, diminish overall piston performance, and accelerate engine component degradation.

Typical Scenarios of Stiction in Pistons

Typical scenarios of stiction in pistons occur during cold starts, where oil film breakdown leads to increased static friction between the piston rings and cylinder walls. Extended engine idle periods can cause oil to drain away from critical surfaces, resulting in piston ring sticking and compromised compression. Additionally, the use of low-quality lubricants or contamination by dirt and debris accelerates stiction, impairing engine efficiency and performance.

Real-World Examples of Piston Stiction

Piston stiction commonly occurs in automotive engines due to corrosion buildup between the piston rings and cylinder walls, often seen in vehicles subjected to long periods of inactivity or harsh environmental conditions. Real-world examples include classic cars stored in humid climates where moisture causes rust formation, leading to increased friction and difficulty in engine startup. This phenomenon can also affect heavy-duty diesel engines operating in cold regions, where low temperatures exacerbate oil thickening and increase the likelihood of piston ring sticking.

Stiction vs. Friction in Piston Movement

Stiction in piston movement refers to the initial resistance that must be overcome to start the piston sliding, caused by static adhesion between the piston and cylinder surfaces. Unlike friction, which is the continuous resistance during motion, stiction results in jerky or stick-slip motion that can reduce engine efficiency and increase wear. Understanding the difference between stiction and friction is crucial for optimizing lubrication strategies and improving piston performance in automotive engines.

Diagnosing Stiction Issues in Pistons

Diagnosing stiction issues in pistons involves measuring unusual resistance during piston movement, often detected through increased engine vibration or irregular idle patterns. Technicians use bore scopes to inspect cylinder walls and piston skirts for varnish buildup or corrosion, common causes of stiction in automotive engines. Oil analysis revealing contaminants or degraded lubrication properties also supports early detection of piston stiction problems.

Preventive Measures Against Piston Stiction

Piston stiction in automotive engines occurs when oil degradation and carbon buildup cause the piston rings to stick within the cylinder bore, leading to reduced engine performance and increased wear. Preventive measures against piston stiction include regular oil changes using high-quality synthetic lubricants, applying cylinder lubricants during assembly, and maintaining optimal engine temperature to prevent oil coking. Implementing controlled break-in procedures and ensuring proper piston ring gap clearance also reduce the risk of stiction in piston assemblies.

Solutions and Treatments for Piston Stiction

Effective solutions for piston stiction in automotive engines include the application of advanced anti-friction coatings such as diamond-like carbon (DLC) or molybdenum disulfide to piston skirts and rings, significantly reducing adhesion during cold starts. Utilizing high-quality synthetic lubricants with enhanced boundary lubrication properties ensures consistent oil film formation, minimizing metal-to-metal contact and preventing stiction-related damage. Regular engine maintenance with periodic piston and cylinder bore inspections, combined with optimized engine assembly tolerances, also plays a critical role in mitigating piston stiction and extending engine life.

example of stiction in piston Infographic

samplerz.com

samplerz.com