Droop in automotive suspension refers to the maximum extension of the suspension system when the wheel moves downward away from the vehicle chassis. An example of droop can be observed in off-road vehicles where the suspension fully extends as the wheel passes over a hump, allowing for maximum wheel articulation and improved traction. This droop is crucial for maintaining contact with uneven terrain and enhancing vehicle stability during extreme maneuvers. In a typical independent suspension system, droop occurs when the suspension arm reaches its lowest position, causing the spring and shock absorber to extend fully. The data from suspension travel sensors can quantify the extent of droop, providing insights into suspension performance and the ability to absorb impacts. Engineers analyze droop limits to optimize ride comfort, handling characteristics, and to prevent mechanical damage due to excessive extension.

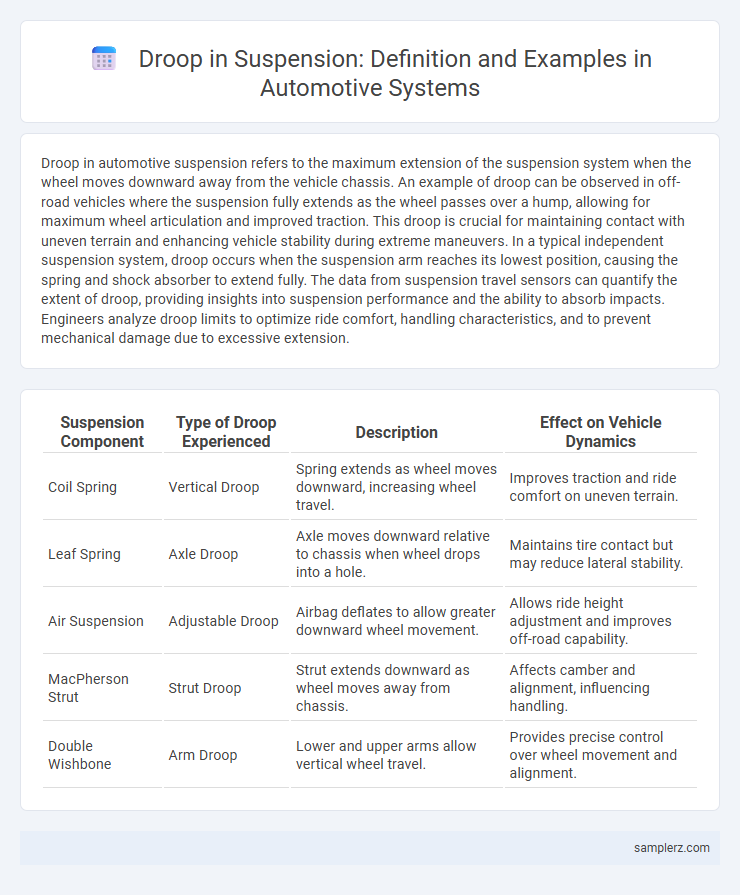

Table of Comparison

| Suspension Component | Type of Droop Experienced | Description | Effect on Vehicle Dynamics |

|---|---|---|---|

| Coil Spring | Vertical Droop | Spring extends as wheel moves downward, increasing wheel travel. | Improves traction and ride comfort on uneven terrain. |

| Leaf Spring | Axle Droop | Axle moves downward relative to chassis when wheel drops into a hole. | Maintains tire contact but may reduce lateral stability. |

| Air Suspension | Adjustable Droop | Airbag deflates to allow greater downward wheel movement. | Allows ride height adjustment and improves off-road capability. |

| MacPherson Strut | Strut Droop | Strut extends downward as wheel moves away from chassis. | Affects camber and alignment, influencing handling. |

| Double Wishbone | Arm Droop | Lower and upper arms allow vertical wheel travel. | Provides precise control over wheel movement and alignment. |

Understanding Suspension Droop: A Brief Overview

Suspension droop refers to the maximum extension of a vehicle's suspension when the wheels are lowered away from the chassis, often occurring during off-road driving or over uneven terrain. This extension allows the wheels to maintain contact with the ground, improving traction and stability in vehicles like trucks and SUVs. Understanding suspension droop is crucial for optimizing ride quality and handling characteristics in automotive design.

Key Components Influencing Droop in Car Suspensions

Droop in car suspensions is primarily influenced by the control arms, coil springs, and shock absorbers working in unison to allow maximum wheel travel below the vehicle's static ride height. The lower control arms determine the suspension's downward range, while coil springs provide the necessary lift and resilience to manage road irregularities. Shock absorbers regulate the rebound rate, ensuring smooth suspension droop and maintaining tire contact with the road for optimal handling and safety.

Suspension Droop vs. Bump: Core Differences

Suspension droop refers to the extension movement when the wheel moves downward away from the vehicle chassis, while bump describes the compression as the wheel moves upward toward the chassis. Droop is crucial for maintaining tire contact during uneven terrain, enhancing traction and stability by allowing the suspension to stretch. In contrast, bump limits maximum compression to prevent bottoming out and damage to suspension components, balancing ride comfort and control.

Droop Travel: Definition and Measurement Techniques

Droop travel in automotive suspension refers to the maximum distance a wheel can extend downward from its neutral position when the vehicle is off the ground, allowing the suspension to reach full extension. Measurement techniques for droop travel typically involve lifting the vehicle to allow maximum suspension extension, then measuring the vertical distance between the wheel hub's neutral and fully extended positions using tools like tape measures or laser distance sensors. Accurate assessment of droop travel is crucial for optimizing ride quality, handling characteristics, and off-road performance in automotive suspension design.

Example of Droop in Modern Independent Suspension Systems

In modern independent suspension systems, droop refers to the maximum extension of the suspension when a wheel hangs freely without load. An example is the MacPherson strut suspension found in many compact cars, where droop allows the wheel to move downward, improving traction on uneven terrain. This extended movement enhances wheel articulation, contributing to ride comfort and handling stability.

Impact of Droop on Ride Comfort and Handling

Excessive droop in automotive suspension leads to reduced tire contact with the road, compromising ride comfort and vehicle stability during uneven terrain navigation. Limited suspension droop restricts wheel articulation, causing harsh impacts and decreased traction on bumpy surfaces. Optimizing droop travel balances improved handling responsiveness with enhanced occupant comfort, critical for performance and off-road vehicles.

Real-World Scenario: Droop in Off-Road Vehicle Suspensions

In off-road vehicles, suspension droop occurs when the wheels extend downward beyond their neutral position as the vehicle navigates uneven terrain, maximizing wheel travel and ground contact. This increased droop improves traction and stability on rocky or uneven surfaces by maintaining tire contact during suspension articulation. The enhanced droop range is critical for off-road vehicles like rock crawlers and trail trucks to prevent wheel lift and maintain control in challenging environments.

Droop Settings in Performance and Racing Applications

Droop settings in suspension determine the maximum extension travel of the shock absorber, crucial for maintaining tire contact during aggressive cornering and uneven track surfaces in performance and racing applications. Optimal droop adjustments prevent wheel lift and improve grip by allowing the suspension to extend fully without losing traction, enhancing vehicle stability at high speeds. Racers fine-tune droop to balance chassis control and suspension compliance, directly affecting lap times and tire wear.

Adjusting Droop for Improved Traction and Stability

Adjusting droop in automotive suspension involves modifying the downward travel of the wheel beyond the static ride height, enhancing traction on uneven terrain. Proper droop settings prevent excessive suspension droop that can cause loss of tire contact, thereby improving stability during cornering and rough road conditions. Accurate calibration of droop height optimizes suspension performance, delivering better control and consistent grip for off-road and performance vehicles.

Common Issues and Solutions Related to Excessive Suspension Droop

Excessive suspension droop in automotive systems often leads to reduced vehicle stability, increased body roll, and compromised handling performance. Common issues include worn or broken coil springs, damaged shock absorbers, and stretched suspension bushings, which cause extended wheel travel and decreased control during cornering. Solutions typically involve replacing faulty components with high-quality OEM parts, installing stiffer springs or adjustable shocks, and ensuring proper suspension alignment to restore optimal ride height and improve overall vehicle dynamics.

example of droop in suspension Infographic

samplerz.com

samplerz.com