A lockup in a torque converter occurs when the clutch inside the torque converter engages to create a direct connection between the engine and the transmission. This engagement eliminates the slippage that typically happens in a torque converter, improving fuel efficiency and reducing heat generation. Lockup clutches are electronically controlled and activate at specific vehicle speeds or engine load conditions. In automotive applications, torque converter lockup enhances drivability by providing smoother acceleration and better power transfer. Modern vehicles use sensors to monitor parameters like vehicle speed, engine RPM, and throttle position to determine the optimal lockup timing. The implementation of lockup clutches contributes to improved overall transmission performance and fuel economy.

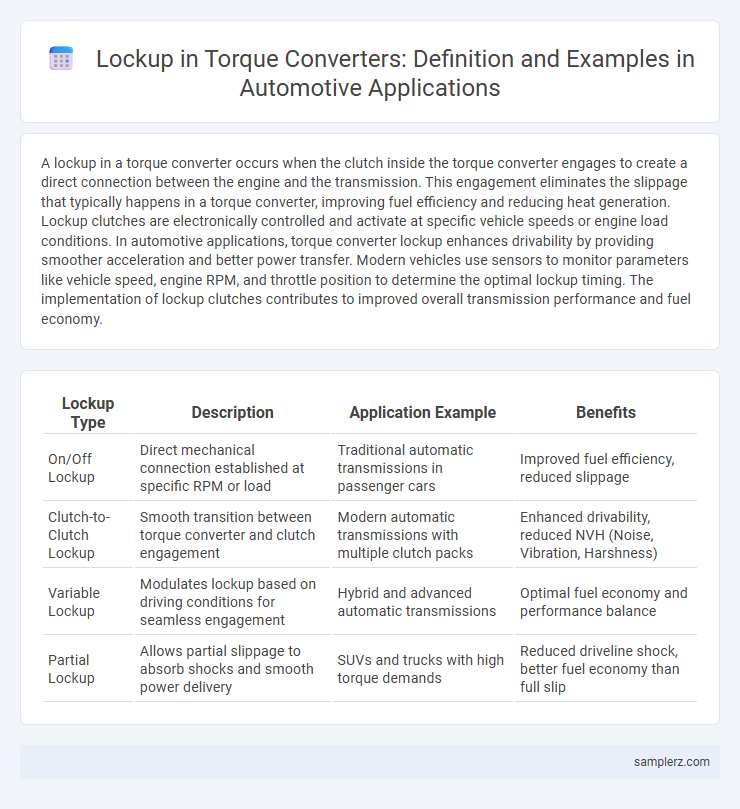

Table of Comparison

| Lockup Type | Description | Application Example | Benefits |

|---|---|---|---|

| On/Off Lockup | Direct mechanical connection established at specific RPM or load | Traditional automatic transmissions in passenger cars | Improved fuel efficiency, reduced slippage |

| Clutch-to-Clutch Lockup | Smooth transition between torque converter and clutch engagement | Modern automatic transmissions with multiple clutch packs | Enhanced drivability, reduced NVH (Noise, Vibration, Harshness) |

| Variable Lockup | Modulates lockup based on driving conditions for seamless engagement | Hybrid and advanced automatic transmissions | Optimal fuel economy and performance balance |

| Partial Lockup | Allows partial slippage to absorb shocks and smooth power delivery | SUVs and trucks with high torque demands | Reduced driveline shock, better fuel economy than full slip |

Understanding Torque Converter Lockup: Automotive Basics

Torque converter lockup enhances fuel efficiency by mechanically connecting the engine to the transmission, eliminating slippage during cruising speeds. This lockup clutch engages once the vehicle reaches a certain speed, allowing direct power transfer and reducing heat buildup inside the torque converter. Modern vehicles utilize electronically controlled lockup mechanisms to optimize engine load and improve overall performance.

Key Components Involved in Torque Converter Lockup

The torque converter lockup mechanism involves key components including the lockup clutch, the torque converter housing, and the hydraulic control system. The lockup clutch engages to create a direct mechanical connection between the engine and the transmission, reducing slippage and improving fuel efficiency. Precision control of hydraulic pressure ensures timely engagement and disengagement of the lockup clutch, optimizing vehicle performance under varying driving conditions.

How Lockup Mechanisms Improve Fuel Efficiency

Lockup mechanisms in torque converters eliminate slippage between the engine and transmission by directly connecting the impeller and turbine, enhancing mechanical efficiency. This direct coupling reduces energy loss, enabling more efficient power transfer and lowering fuel consumption during steady-speed driving. By minimizing heat generation and maintaining optimal engine load, lockup clutches contribute significantly to improved fuel economy in modern automatic transmissions.

Example of Lockup Operation During Highway Cruising

During highway cruising, the torque converter lockup clutch engages to create a direct mechanical connection between the engine and transmission, improving fuel efficiency by eliminating slippage. This lockup operation reduces heat generation and enhances power transfer, maintaining steady vehicle speed with lower RPM. For example, a vehicle traveling at 65 mph may engage the lockup clutch to optimize torque delivery and minimize fuel consumption.

Symptoms of Faulty Torque Converter Lockup

Symptoms of a faulty torque converter lockup include engine overheating, shuddering or vibration at cruising speeds, and a noticeable drop in fuel efficiency. Drivers may experience slipping or delayed acceleration, alongside erratic shifting patterns in automatic transmissions. These signs often indicate that the torque converter is failing to engage the lockup clutch properly, impairing power transfer and overall vehicle performance.

Common Vehicles Featuring Lockup Torque Converters

Common vehicles featuring lockup torque converters include models like the Toyota Camry, Ford F-150, and Honda Accord, which utilize this technology to enhance fuel efficiency and reduce transmission heat. Lockup torque converters are standard in many automatic transmissions across brands such as Chevrolet, Nissan, and Hyundai, improving engine performance during highway driving. These vehicles benefit from improved torque transfer and decreased slippage, leading to smoother acceleration and better overall drivability.

Lockup Clutch Engagement: Step-by-Step Example

Lockup clutch engagement in a torque converter occurs when the transmission control module signals the clutch to engage, reducing slippage and improving fuel efficiency. During acceleration, hydraulic pressure increases, pressing the clutch plates together and establishing a direct mechanical connection between the engine and transmission. This lockup eliminates torque converter losses, resulting in smoother power transfer and enhanced vehicle performance.

Impact of Lockup on Transmission Performance

Lockup in a torque converter eliminates slip between the engine and transmission, significantly improving fuel efficiency and reducing heat generation. This direct coupling enhances transmission performance by providing smoother acceleration and better throttle response under steady-state cruising conditions. The lockup mechanism also reduces wear on transmission components, extending the overall lifespan of the drivetrain system.

Diagnosing Lockup Issues in Automatic Transmissions

Diagnosing lockup issues in automatic transmissions requires checking for symptoms such as shuddering, slipping, or delayed engagement during vehicle acceleration. Technicians use scan tools to monitor transmission control module (TCM) data, including lockup clutch apply counts and solenoid operation, to identify faults in the torque converter lockup mechanism. Inspecting hydraulic circuits and verifying proper fluid pressure ensures the lockup clutch functions correctly, preventing power loss and improving fuel efficiency.

Modern Advancements in Torque Converter Lockup Technology

Modern advancements in torque converter lockup technology include the integration of electronically controlled locking clutches that enhance fuel efficiency by reducing slippage during acceleration. Adaptive lockup systems utilize real-time data from the engine and transmission to optimize engagement timing, improving drivability and reducing emissions. These innovations enable smoother transitions between torque multiplication and direct drive, translating to better performance and longevity in modern vehicles.

example of lockup in torque converter Infographic

samplerz.com

samplerz.com