Turbo lag occurs when there is a delay between the driver pressing the accelerator and the turbocharger providing increased engine boost. This phenomenon happens because the turbo relies on exhaust gases to spin its turbine, which takes a moment to reach optimal speed. For instance, when accelerating from a stop, the car may feel sluggish until the turbo spools up and delivers maximum boost pressure. During turbo lag, engine power output remains lower than expected despite throttle input, affecting vehicle responsiveness. Modern turbo systems use technologies like variable geometry turbines and twin-scroll designs to reduce lag time. Data shows that turbo lag can vary from 0.1 to several seconds depending on turbo size, engine speed, and exhaust flow dynamics.

Table of Comparison

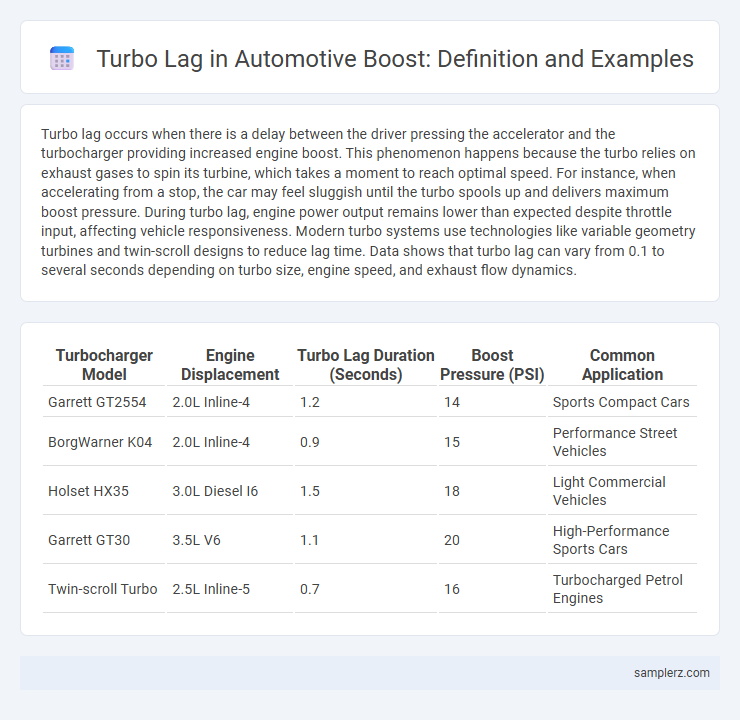

| Turbocharger Model | Engine Displacement | Turbo Lag Duration (Seconds) | Boost Pressure (PSI) | Common Application |

|---|---|---|---|---|

| Garrett GT2554 | 2.0L Inline-4 | 1.2 | 14 | Sports Compact Cars |

| BorgWarner K04 | 2.0L Inline-4 | 0.9 | 15 | Performance Street Vehicles |

| Holset HX35 | 3.0L Diesel I6 | 1.5 | 18 | Light Commercial Vehicles |

| Garrett GT30 | 3.5L V6 | 1.1 | 20 | High-Performance Sports Cars |

| Twin-scroll Turbo | 2.5L Inline-5 | 0.7 | 16 | Turbocharged Petrol Engines |

What Is Turbo Lag?

Turbo lag is the delay between pressing the accelerator and the turbocharger providing increased engine power due to the time needed for exhaust gases to spool the turbine. This phenomenon occurs because the turbocharger relies on exhaust flow to spin the turbine, and at low engine speeds, insufficient exhaust flow results in slower boost build-up. Understanding turbo lag is crucial for optimizing boost response and improving overall engine performance in turbocharged vehicles.

Common Signs of Turbo Lag in Vehicles

Common signs of turbo lag in vehicles include a noticeable delay in engine response when accelerating, a temporary drop in power before the turbocharger engages, and a surge of boost pressure after the initial hesitation. Drivers often experience a lack of immediate throttle response, especially at lower RPMs, which can affect overall driving performance. Turbo lag is typically more evident in smaller displacement engines equipped with turbochargers, impacting acceleration smoothness and driving dynamics.

Real-World Example: Turbo Lag in Daily Driving

Turbo lag is frequently experienced in daily driving when accelerating from a standstill or low RPMs, such as merging onto a highway. During these moments, the turbocharger takes time to spool up, causing a noticeable delay before the engine delivers increased boost and power. This lag occurs because the exhaust gases have not yet reached sufficient velocity to spin the turbo's turbine effectively.

Turbo Lag During Acceleration: Case Studies

Turbo lag during acceleration occurs when the turbocharger takes time to spool up and generate boost pressure, causing a delay in power delivery. In a Volkswagen Golf GTI, this lag generally lasts around 0.5 to 1 second as the turbo reaches optimal RPM, impacting initial throttle response. Similarly, in a Ford EcoBoost Mustang, engineers minimized lag to approximately 0.3 seconds using twin-scroll turbo technology, enhancing acceleration smoothness and reducing the perceived boost delay.

Turbo Lag Effects on High-Performance Cars

Turbo lag in high-performance cars causes a noticeable delay between throttle input and engine response, resulting in reduced acceleration during critical moments. This delay occurs because the turbocharger requires time to spool up and produce sufficient boost pressure, impacting overall driving dynamics and track performance. Engineers mitigate turbo lag through advanced technologies like twin-scroll turbos, variable geometry turbines, and electric assistance to enhance boost delivery and responsiveness.

How Engine Load Influences Turbo Boost Response

Turbo lag occurs when a delay happens between throttle input and the turbocharger's boost response, primarily influenced by engine load. Higher engine loads increase exhaust gas flow, accelerating turbo spool-up and reducing lag, while lower loads result in slower spool speeds and delayed boost onset. Understanding the relationship between engine load and turbo boost response helps optimize turbocharger performance and enhance overall engine efficiency.

Comparing Old vs. Modern Turbo Lag Performance

Older turbochargers exhibited significant turbo lag due to slower spool times and less efficient wastegate management, often resulting in delayed boost delivery at low RPMs. Modern turbo systems utilize advanced materials, variable geometry turbines, and electronic boost control to minimize lag, providing near-instantaneous throttle response and improved power delivery across the rev range. This evolution in turbo technology enhances fuel efficiency and driving dynamics, making modern turbocharged engines more responsive and enjoyable compared to their predecessors.

Turbo Lag in Diesel vs. Gasoline Engines

Turbo lag in diesel engines is generally less pronounced compared to gasoline engines due to the typically lower exhaust gas temperatures and higher torque at low RPMs, which help spool the turbocharger more quickly. Gasoline engines often experience more noticeable turbo lag because of higher RPM ranges and lower cylinder pressures, which delay the buildup of sufficient exhaust flow to spin the turbocharger promptly. Understanding the differences in turbo lag between diesel and gasoline engines is crucial for optimizing turbocharger design and improving throttle response in automotive applications.

Impact of Turbocharger Size on Boost Lag

Larger turbochargers often generate significant boost pressure but suffer from increased turbo lag due to the greater inertia of the turbine wheel, delaying spool-up time. Smaller turbos spool faster, reducing lag and providing quicker throttle response but may produce less maximum boost pressure. Balancing turbocharger size is critical for optimizing boost performance and minimizing lag in automotive engines.

Solutions and Upgrades to Minimize Turbo Lag

Turbo lag, the delay between pressing the accelerator and the turbocharger's boost response, can be minimized through solutions like installing a twin-scroll turbocharger, which improves exhaust gas flow and reduces spool time. Upgrading to an electronic wastegate or a variable geometry turbocharger (VGT) enhances boost control and responsiveness under varying engine loads. Supplementary modifications such as increasing intercooler efficiency and optimizing engine tuning software also contribute to faster and more consistent turbo boost delivery.

example of turbo lag in boost Infographic

samplerz.com

samplerz.com