An A-arm, also known as a control arm, is a critical component of automotive suspension systems. It connects the vehicle's chassis to the wheel hub, allowing for controlled motion and stability during driving. Typically shaped like the letter "A," it comprises two points attached to the frame and one to the wheel assembly. The A-arm's primary function is to maintain proper alignment of the wheels and absorb road shocks, ensuring a smooth ride. These components are commonly made from steel or aluminum to combine strength and lightweight properties. In double wishbone suspension setups, the upper and lower A-arms work together to optimize wheel movement and improve handling performance.

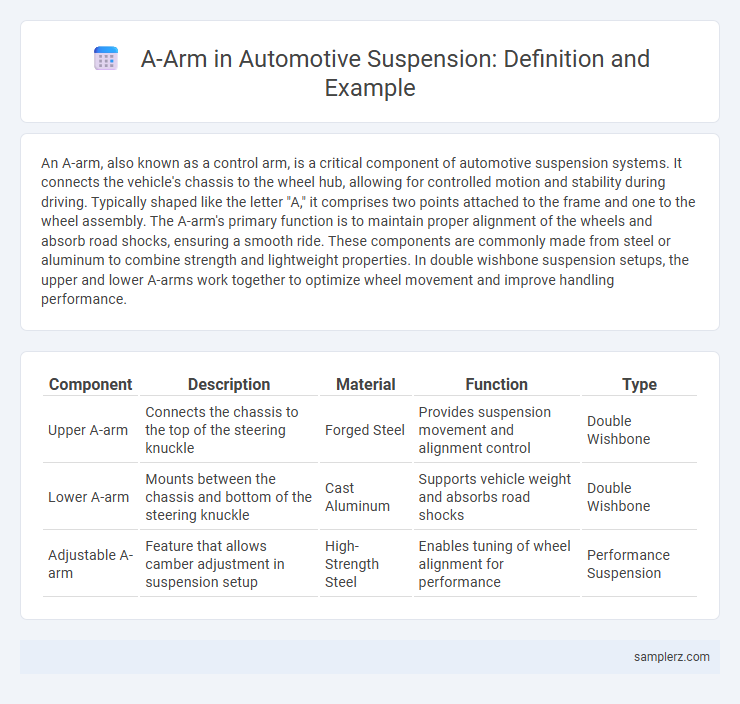

Table of Comparison

| Component | Description | Material | Function | Type |

|---|---|---|---|---|

| Upper A-arm | Connects the chassis to the top of the steering knuckle | Forged Steel | Provides suspension movement and alignment control | Double Wishbone |

| Lower A-arm | Mounts between the chassis and bottom of the steering knuckle | Cast Aluminum | Supports vehicle weight and absorbs road shocks | Double Wishbone |

| Adjustable A-arm | Feature that allows camber adjustment in suspension setup | High-Strength Steel | Enables tuning of wheel alignment for performance | Performance Suspension |

Introduction to A-Arm Suspension in Automobiles

A-arm suspension, also known as double wishbone suspension, features two triangular-shaped arms that connect the wheel hub to the vehicle frame, offering precise control of wheel motion. This design enhances handling, stability, and ride comfort by optimizing camber angles throughout the suspension travel. Commonly used in performance and luxury vehicles, A-arm suspension improves tire contact with the road, resulting in superior traction and cornering capabilities.

Key Functions of A-Arm Components

A-arms in automotive suspension systems provide precise wheel alignment and maintain optimal tire contact with the road surface, enhancing vehicle stability and handling. These components facilitate controlled vertical wheel movement, absorbing shocks and reducing vibrations for improved ride comfort. Constructed from high-strength materials, A-arms also ensure durability and resistance to deformation under dynamic driving conditions.

Classic Cars Featuring A-Arm Suspensions

Classic cars like the Chevrolet Bel Air and Ford Mustang prominently feature A-arm suspensions, offering improved ride quality and handling through their double wishbone design. This setup uses upper and lower control arms to maintain wheel alignment and absorb road shocks effectively. Enthusiasts value A-arm suspensions for their durability and precise control in vintage muscle cars and classic cruisers.

A-Arm vs. MacPherson Strut: Comparative Overview

The A-arm suspension, also known as double wishbone suspension, offers superior control and handling due to its two-arm design that maintains better camber angles during wheel travel compared to the MacPherson strut, which combines a shock absorber and coil spring in a single unit. While the A-arm system provides enhanced stability and precise steering, it is more complex and expensive to manufacture and maintain than the simpler, more cost-effective MacPherson strut commonly used in front suspensions of compact and mid-sized vehicles. Vehicle designers often choose A-arm setups for performance and luxury cars prioritizing ride quality, whereas MacPherson struts are preferred for their space efficiency and lower production costs.

Anatomy of a Double Wishbone (A-Arm) Setup

A double wishbone suspension setup features two A-arms per wheel, each shaped like a triangle with ball joints connecting the chassis to the wheel hub, enabling precise wheel control and improved handling. The upper and lower A-arms work together to maintain optimal camber angles during suspension travel, enhancing tire contact with the road. This design allows for greater suspension articulation and stability, essential in high-performance and off-road vehicles.

Performance Vehicles Utilizing A-Arm Suspensions

Performance vehicles frequently utilize A-arm suspensions for their precise wheel control and superior handling dynamics. The double A-arm setup allows for optimal camber adjustment, enhancing tire contact and grip during aggressive cornering. High-performance sports cars such as the Chevrolet Corvette and Ford Mustang often incorporate this suspension type to maximize agility and driving responsiveness.

Off-Road Applications of A-Arms

A-arms in off-road suspension systems enhance wheel articulation and durability, crucial for uneven terrain navigation. Manufactured from high-strength steel or aluminum alloys, these components absorb substantial impacts while maintaining precise wheel alignment. Their design allows for increased suspension travel, significantly improving vehicle stability and traction in rugged environments.

Maintenance Tips for A-Arm Suspension Systems

Regular inspection of A-arm suspension systems is crucial to ensure vehicle stability and handling performance, paying close attention to worn ball joints and bushings for timely replacement. Proper lubrication of all pivot points prevents premature wear and extends the lifespan of suspension components. Maintaining correct alignment after any repair or replacement guarantees optimal tire contact and enhances driving safety.

Common Issues in A-Arm Suspension Assemblies

Common issues in A-arm suspension assemblies include ball joint wear, which causes excessive play and uneven tire wear, and bushing deterioration that leads to vibrations and poor handling. Corrosion and physical damage to the A-arm can compromise structural integrity, resulting in misalignment and steering difficulties. Regular inspection and timely replacement of these components are essential for maintaining optimal suspension performance and vehicle safety.

Future Trends in A-Arm Suspension Design

Future trends in A-arm suspension design emphasize lightweight materials such as carbon fiber composites and aluminum alloys to enhance vehicle efficiency and performance. Integration of adaptive and active suspension systems using sensors and AI algorithms improves ride comfort and handling by dynamically adjusting arm positions. Advanced manufacturing techniques like 3D printing enable complex geometries that optimize strength-to-weight ratios and reduce production costs in next-generation A-arm components.

example of A-arm in suspension Infographic

samplerz.com

samplerz.com