A knuckle in automotive suspension acts as a critical connector between the wheel hub and the suspension components. It supports the steering mechanism and ensures the wheel maintains proper alignment during movement. Typically, the knuckle is found in MacPherson strut and double-wishbone suspension systems, where it allows for controlled pivoting of the wheel. The design of suspension knuckles varies based on vehicle type and suspension setup, often made from forged steel or aluminum for strength and durability. It interfaces with components such as control arms, tie rods, and wheel bearings, enabling smooth and stable steering function. Proper functioning of the knuckle is essential for handling, ride comfort, and safety in automotive engineering.

Table of Comparison

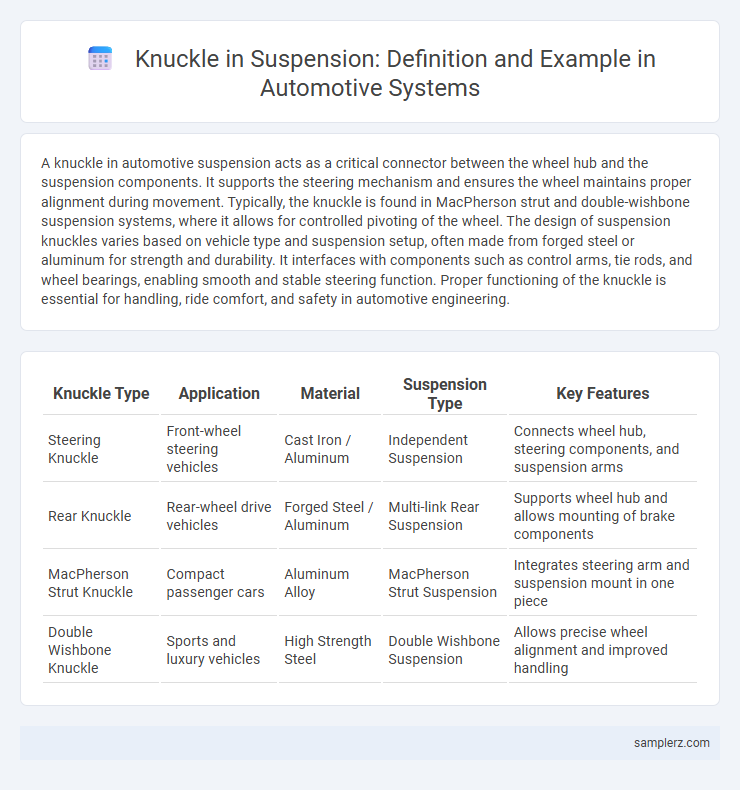

| Knuckle Type | Application | Material | Suspension Type | Key Features |

|---|---|---|---|---|

| Steering Knuckle | Front-wheel steering vehicles | Cast Iron / Aluminum | Independent Suspension | Connects wheel hub, steering components, and suspension arms |

| Rear Knuckle | Rear-wheel drive vehicles | Forged Steel / Aluminum | Multi-link Rear Suspension | Supports wheel hub and allows mounting of brake components |

| MacPherson Strut Knuckle | Compact passenger cars | Aluminum Alloy | MacPherson Strut Suspension | Integrates steering arm and suspension mount in one piece |

| Double Wishbone Knuckle | Sports and luxury vehicles | High Strength Steel | Double Wishbone Suspension | Allows precise wheel alignment and improved handling |

Introduction to Suspension Knuckles

Suspension knuckles serve as critical components connecting the wheel hub to the suspension and steering system, enabling precise wheel movement and support. Typically made from forged steel or aluminum alloys, knuckles provide structural integrity and facilitate the attachment points for control arms, tie rods, and shock absorbers in vehicles. Their design impacts handling performance, durability, and alignment, making them essential for both safety and ride quality in automotive suspension systems.

Key Functions of a Suspension Knuckle

A suspension knuckle serves as the pivotal connection point between the wheel hub, steering components, and suspension system, enabling precise wheel alignment and movement. It supports the vehicle's weight while allowing for smooth steering and suspension articulation, ensuring optimal handling and ride comfort. By securely mounting brake components and facilitating load transfer, the suspension knuckle plays a critical role in vehicle stability and safety.

Common Knuckle Designs in Automotive Suspensions

Common knuckle designs in automotive suspensions include the traditional stamped steel knuckle, forged aluminum knuckle, and cast iron knuckle, each offering unique strength and weight characteristics. Forged aluminum knuckles are favored in performance vehicles for their lightweight properties and high tensile strength, enhancing handling and fuel efficiency. Stamped steel knuckles provide cost-effective durability in mass-market vehicles, while cast iron knuckles offer exceptional robustness for heavy-duty applications like trucks and SUVs.

Front Suspension Knuckle Examples

Front suspension knuckles, such as the MacPherson strut knuckle and the double-wishbone knuckle, serve as critical pivot points connecting the wheel hub to the suspension system. The MacPherson strut knuckle integrates with the strut assembly and steering components, optimizing space and weight for compact front suspensions. Double-wishbone front knuckles support greater steering precision and durability by accommodating upper and lower control arms, commonly found in performance and heavy-duty vehicles.

Rear Suspension Knuckle Configurations

Rear suspension knuckle configurations commonly include multi-link and trailing arm setups, each designed to optimize wheel alignment and handling performance under varying load conditions. The knuckle serves as the pivotal connection point between the wheel hub, suspension arms, and shock absorbers, directly influencing vehicle stability and ride comfort. Advanced materials like forged aluminum or high-strength steel are often used to enhance durability while minimizing unsprung weight in modern rear suspension designs.

Material Choices for Automotive Knuckles

Automotive knuckles are commonly crafted from forged steel, aluminum alloys, or cast iron to achieve the ideal balance between strength, weight, and durability. Forged steel offers superior tensile strength and fatigue resistance, enhancing vehicle safety and longevity, while aluminum alloys reduce unsprung weight for improved handling and fuel efficiency. Material selection depends on factors such as manufacturing cost, performance requirements, and corrosion resistance in automotive suspension systems.

Role of Knuckles in Steering and Alignment

Knuckles in automotive suspension serve as pivotal components connecting the wheel hub to the suspension and steering systems, allowing for precise wheel movement and steering control. They maintain proper wheel alignment by ensuring the correct camber, caster, and toe angles, which directly affects vehicle handling and tire wear. The role of knuckles is crucial in translating steering inputs into wheel direction while supporting the dynamic loads encountered during driving.

Knuckle Integration with Disc and Drum Brakes

The knuckle serves as a critical component in the suspension system, integrating seamlessly with both disc and drum brakes to enable efficient vehicle control and safety. In disc brake systems, the knuckle supports the caliper and allows the rotor to spin freely while facilitating precise braking force application. For drum brakes, the knuckle connects the backing plate and wheel hub, ensuring stable brake shoe operation and consistent stopping power under various driving conditions.

Signs of Knuckle Wear or Failure

Signs of knuckle wear or failure in automotive suspension include uneven tire wear, noticeable steering vibration, and clunking noises during turns or over bumps. A worn knuckle can cause misalignment, leading to poor handling and increased tire degradation. Inspecting the knuckle for cracks, corrosion, or play in the wheel bearing can help diagnose potential suspension issues.

Advances in Suspension Knuckle Technology

Advances in suspension knuckle technology have led to the integration of lightweight materials such as forged aluminum and composites, enhancing vehicle handling and fuel efficiency. Precision manufacturing techniques like 3D printing and CNC machining allow for complex geometries that improve strength-to-weight ratios and reduce vibration. These innovations contribute to increased durability and optimized steering responsiveness in modern automotive suspension systems.

example of knuckle in suspension Infographic

samplerz.com

samplerz.com