A detent in a gear selector refers to a mechanism that provides tactile feedback and positional stability to the driver when shifting gears. This mechanism typically consists of notches or grooves along with a spring-loaded pin or ball that fits into these notches. The detent ensures the gear lever stays securely in the chosen gear, preventing accidental shifts while driving. In automotive applications, detents are critical for both manual and automatic transmissions. For example, in a manual transmission gear selector, detents align the gear shift lever precisely with the gears, enabling smoother gear engagement and reducing wear. Data from vehicle studies show that well-designed detent systems improve driver confidence and contribute to safer gear shifting experiences.

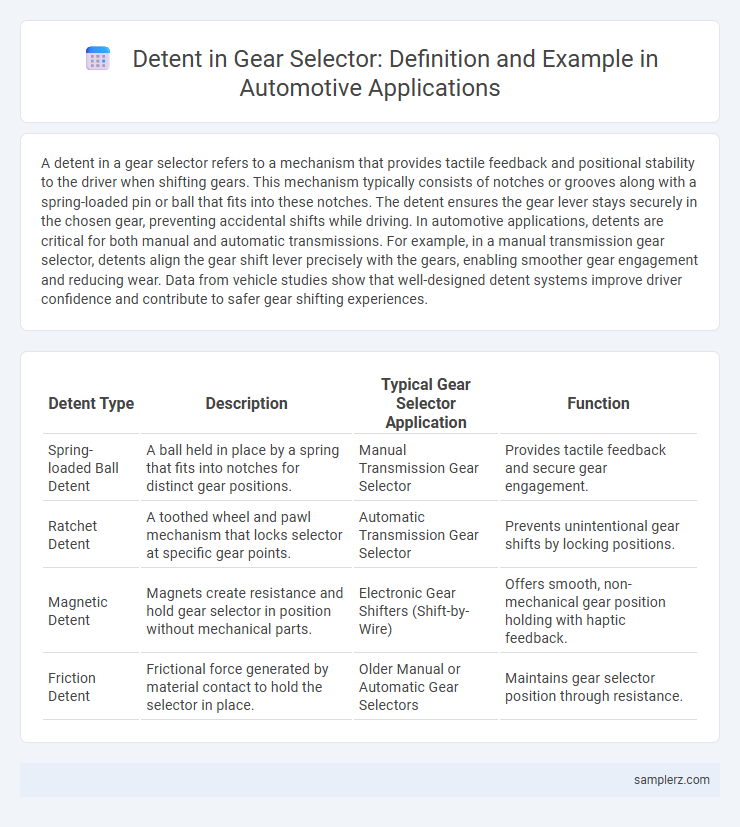

Table of Comparison

| Detent Type | Description | Typical Gear Selector Application | Function |

|---|---|---|---|

| Spring-loaded Ball Detent | A ball held in place by a spring that fits into notches for distinct gear positions. | Manual Transmission Gear Selector | Provides tactile feedback and secure gear engagement. |

| Ratchet Detent | A toothed wheel and pawl mechanism that locks selector at specific gear points. | Automatic Transmission Gear Selector | Prevents unintentional gear shifts by locking positions. |

| Magnetic Detent | Magnets create resistance and hold gear selector in position without mechanical parts. | Electronic Gear Shifters (Shift-by-Wire) | Offers smooth, non-mechanical gear position holding with haptic feedback. |

| Friction Detent | Frictional force generated by material contact to hold the selector in place. | Older Manual or Automatic Gear Selectors | Maintains gear selector position through resistance. |

Introduction to Detent Mechanisms in Gear Selectors

Detent mechanisms in automotive gear selectors provide precise tactile feedback by locking the gear lever into defined positions, ensuring accurate gear engagement. These systems typically use spring-loaded balls or tabs that fit into notches or grooves along the gear selector shaft, enhancing shift accuracy and preventing unintended gear changes. Engineered for durability, detents improve overall driving safety and comfort by creating a reliable and consistent shifting experience.

The Role of Detents in Automotive Gear Selection

Detents in automotive gear selectors provide tactile feedback and ensure precise gear positioning by creating distinct "clicks" or stops that prevent unintentional gear shifts. These mechanical notches improve driver confidence and safety by maintaining gear engagement even during vibrations or sudden movements. High-quality detent systems enhance transmission durability and overall vehicle performance by reducing wear and minimizing gear slippage.

Types of Detents Used in Gear Selectors

Common types of detents used in automotive gear selectors include ball detents, spring detents, and cam detents, each providing distinct tactile feedback and positional stability. Ball detents use a spring-loaded ball bearing to lock gears into place, ensuring precise engagement and smooth shifting. Spring detents rely on tensioned springs to hold the selector at specific gear positions, while cam detents utilize a shaped cam mechanism to create defined stop points for more secure gear positioning.

Mechanical Detent Examples in Manual Gear Selectors

Mechanical detents in manual gear selectors provide tactile feedback and positional stability by using spring-loaded balls or pawls that engage with notches or grooves on the shift rail. This system ensures precise gear engagement and prevents unintentional gear slips during operation. Common examples include ball detent mechanisms in traditional H-pattern gearboxes and pawl-and-notch arrangements found in motorcycle gear selectors.

Electronic Detent Implementation in Automatic Transmissions

Electronic detent implementation in automatic transmissions enhances gear selector precision by using sensors and actuators to simulate tactile feedback traditionally provided by mechanical detents. This system improves shift accuracy and reliability through real-time electronic control, reducing wear and allowing for smoother gear changes. Advanced electronic detents integrate seamlessly with transmission control units (TCUs), optimizing performance and enabling adaptive shift patterns based on driving conditions.

Detent Spring Function in Gear Shift Stability

The detent spring in a gear selector ensures precise gear engagement by providing tactile feedback and resistance, preventing accidental shifts and enhancing overall driving safety. Its function stabilizes the gear shift mechanism by holding the gear lever firmly within each notch or position, reducing gear slippage and improving shift accuracy. High-quality detent springs contribute to smoother gear transitions and increased longevity of the transmission system in automotive applications.

Common Detent Locations in Gear Selector Assemblies

Common detent locations in gear selector assemblies include the shift lever pivot, where clicks correspond to gear positions for tactile feedback, and the transmission linkage, providing precise gear engagement. Another typical detent location is within the shift gate mechanism, ensuring secure gear placement and preventing unintentional shifts. These detent points contribute to improved driver control and enhanced transmission reliability in modern automotive gear selector systems.

Symptoms of Faulty Detent Mechanisms

A faulty detent mechanism in a gear selector often causes difficulty in shifting gears, with the transmission hesitating or slipping out of gear unexpectedly. Drivers may experience a loose or vague feeling during gear changes, accompanied by abnormal noises or grinding sounds. Such symptoms indicate worn or damaged detent springs, pawls, or notches that fail to securely hold the gear position, compromising vehicle safety and performance.

Maintenance Tips for Gear Selector Detent Systems

Regularly inspect the gear selector detent for signs of wear or damage to ensure smooth shifting and prevent gear slippage. Applying appropriate lubricant to the detent mechanism reduces friction and extends the lifespan of the components. Periodic cleaning of the detent grooves and springs prevents dirt accumulation that can hinder selector performance in automotive transmission systems.

Innovations in Detent Design for Modern Vehicles

Innovations in detent design for gear selectors have enhanced tactile feedback and shift precision in modern vehicles by integrating magnetorheological fluid technology and electronically controlled detent systems. Advanced materials such as high-durability polymers and precision-machined alloys improve wear resistance and reduce noise during gear transitions. These developments contribute to smoother gear engagement, increased driver confidence, and extended component lifespan in automatic and manual transmissions.

example of detent in gear selector Infographic

samplerz.com

samplerz.com