In the automotive industry, the rotor in a distributor serves as a vital component in ignition systems. It is a rotating arm inside the distributor cap that directs high voltage from the ignition coil to the correct cylinder's spark plug via the distributor cap's contacts. This precise distribution of electrical energy ensures proper timing for spark ignition, critical for efficient engine performance. The rotor typically connects to the distributor shaft, driven by the engine's camshaft, ensuring synchronization with the engine's firing order. It is usually made of durable, heat-resistant materials to withstand high operating temperatures and electrical stress. Modern vehicles may use electronic ignition systems, but traditional rotor-based distributors remain prevalent in many classic and performance engines.

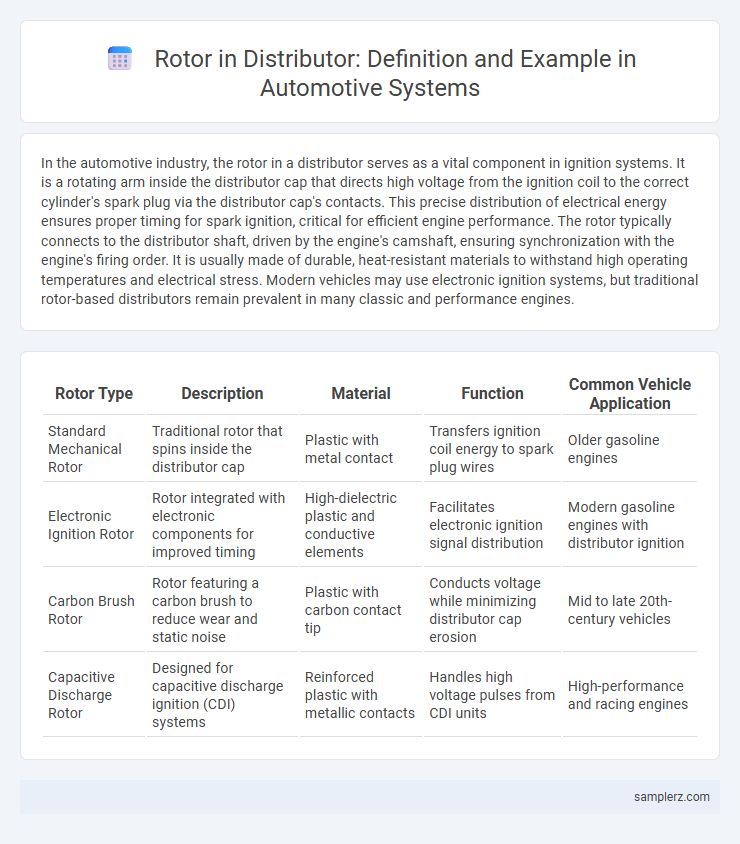

Table of Comparison

| Rotor Type | Description | Material | Function | Common Vehicle Application |

|---|---|---|---|---|

| Standard Mechanical Rotor | Traditional rotor that spins inside the distributor cap | Plastic with metal contact | Transfers ignition coil energy to spark plug wires | Older gasoline engines |

| Electronic Ignition Rotor | Rotor integrated with electronic components for improved timing | High-dielectric plastic and conductive elements | Facilitates electronic ignition signal distribution | Modern gasoline engines with distributor ignition |

| Carbon Brush Rotor | Rotor featuring a carbon brush to reduce wear and static noise | Plastic with carbon contact tip | Conducts voltage while minimizing distributor cap erosion | Mid to late 20th-century vehicles |

| Capacitive Discharge Rotor | Designed for capacitive discharge ignition (CDI) systems | Reinforced plastic with metallic contacts | Handles high voltage pulses from CDI units | High-performance and racing engines |

Understanding the Role of Rotors in Distributor Systems

Rotors in distributor systems play a crucial role in directing high-voltage electricity from the ignition coil to the correct spark plug at precise timing, ensuring efficient engine combustion. Typically made from durable, heat-resistant materials, rotors spin inside the distributor cap and transfer electrical current via a metal arm that aligns with contact points for each cylinder. Proper functioning of the rotor is essential for optimizing ignition timing, reducing misfires, and enhancing overall engine performance.

Key Functions of Distributor Rotors in Automotive Ignition

Distributor rotors play a crucial role in the automotive ignition system by transferring high voltage from the ignition coil to the correct cylinder's spark plug, ensuring precise fire timing. They facilitate the directional flow of electrical current within the distributor cap, enabling smooth engine operation and optimal combustion efficiency. Reliable rotor performance directly impacts engine power output, fuel efficiency, and emissions control.

Common Materials Used in Distributor Rotors

Distributor rotors are commonly made from durable materials such as phenolic resin and Bakelite, known for their excellent electrical insulation properties and heat resistance. Some high-performance rotors utilize carbon-impregnated plastics to improve conductivity and reduce sparking. These materials ensure reliable ignition system performance by maintaining structural integrity and electrical insulation under engine operating conditions.

How Rotor Design Influences Distributor Performance

Rotor design in automotive distributors directly impacts ignition timing accuracy and engine performance by ensuring precise electrical current transfer to spark plugs. High-quality materials and aerodynamic shapes reduce electrical resistance and wear, enhancing durability and consistent spark delivery. Optimized rotor geometry improves distributor efficiency, resulting in smoother engine operation and better fuel combustion.

Step-by-Step Example: Rotor Operation in Classic Cars

The rotor in a classic car distributor spins inside the distributor cap, making contact with each ignition point in sequence to deliver high voltage from the ignition coil. As the engine's camshaft rotates, the rotor arm aligns with the cap terminals, distributing the spark to the correct cylinder at the precise timing. This mechanical process ensures efficient combustion by synchronizing spark delivery with piston position in traditional gasoline engines.

Typical Signs of a Failing Distributor Rotor

A failing distributor rotor often exhibits symptoms such as engine misfires, rough idling, and difficulty starting the vehicle. Signs include visible wear, cracks, or carbon tracking on the rotor arm, which disrupts the electrical current flow to spark plugs. Ignoring these symptoms can lead to decreased engine performance and increased emissions.

Importance of Rotor Maintenance in Ignition Systems

Rotor maintenance in ignition systems is critical for ensuring efficient engine performance and preventing misfires. A worn or damaged rotor disrupts the precise distribution of electrical current to the spark plugs, leading to reduced fuel combustion and increased emissions. Regular inspection and replacement of the rotor maximize ignition system reliability and prolong overall engine lifespan.

OEM vs Aftermarket Distributor Rotors: A Comparative Example

OEM distributor rotors are engineered to meet precise specifications set by vehicle manufacturers, ensuring optimal contact, durability, and consistent performance in ignition systems. Aftermarket distributor rotors vary widely in quality, with some offering equivalent functionality at reduced costs while others may compromise on material integrity, potentially causing premature wear or electrical misfiring. Comparing the thermal resistance and conductive properties between OEM and aftermarket rotors highlights critical differences that impact a vehicle's ignition timing accuracy and overall engine efficiency.

Case Study: Rotor Performance in Modern Engine Distributors

Rotor performance in modern engine distributors significantly impacts ignition timing and engine efficiency. Case studies reveal that advanced composite rotors reduce wear and electrical resistance, enhancing spark delivery and durability under high RPM conditions. Optimized rotor design contributes to precise ignition control, minimizing misfires and improving fuel economy in contemporary automotive engines.

Troubleshooting Ignition Issues Related to Distributor Rotors

Distributor rotors play a crucial role in directing high voltage from the ignition coil to the correct cylinder, making their proper function vital for engine performance. Symptoms of a faulty rotor include engine misfires, rough idling, and difficulty starting, often traced to cracked, worn, or corroded rotor contacts. Inspecting the rotor for physical damage, checking for electrical continuity, and replacing worn components can effectively resolve ignition issues related to distributor rotors.

example of rotor in distributor Infographic

samplerz.com

samplerz.com