Porting in a cylinder head involves modifying the intake and exhaust ports to improve airflow and engine performance. This process typically includes smoothing the surfaces, enlarging the port openings, and reshaping the passageways to reduce turbulence and increase volumetric efficiency. Effective porting can lead to significant gains in horsepower, torque, and fuel efficiency by optimizing the air-fuel mixture flow into and out of the combustion chamber. In automotive engineering, porting requires precise measurements and data analysis to ensure compatibility with the engine's design and operating conditions. Using tools like flow benches and 3D scanners, technicians gather data on airflow dynamics to make informed adjustments in the port geometry. Entities involved in porting include automotive performance shops, engine builders, and manufacturers specializing in cylinder head enhancements for both racing and street applications.

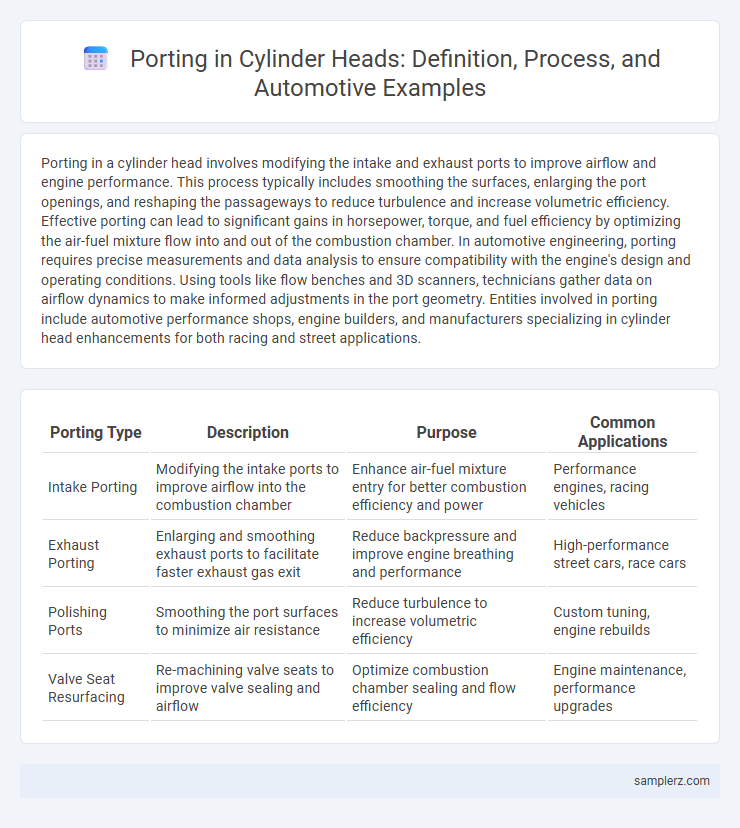

Table of Comparison

| Porting Type | Description | Purpose | Common Applications |

|---|---|---|---|

| Intake Porting | Modifying the intake ports to improve airflow into the combustion chamber | Enhance air-fuel mixture entry for better combustion efficiency and power | Performance engines, racing vehicles |

| Exhaust Porting | Enlarging and smoothing exhaust ports to facilitate faster exhaust gas exit | Reduce backpressure and improve engine breathing and performance | High-performance street cars, race cars |

| Polishing Ports | Smoothing the port surfaces to minimize air resistance | Reduce turbulence to increase volumetric efficiency | Custom tuning, engine rebuilds |

| Valve Seat Resurfacing | Re-machining valve seats to improve valve sealing and airflow | Optimize combustion chamber sealing and flow efficiency | Engine maintenance, performance upgrades |

Introduction to Cylinder Head Porting

Cylinder head porting enhances engine performance by reshaping and smoothing intake and exhaust ports to improve airflow dynamics and combustion efficiency. This process reduces air resistance and increases volumetric efficiency, resulting in higher horsepower and torque output. Precision grinding and matching of ports to valve sizes optimize air-fuel mixture flow, critical in high-performance and racing engines.

Importance of Porting in Engine Performance

Porting in a cylinder head enhances engine performance by optimizing airflow, which increases combustion efficiency and power output. Precise port modifications reduce air resistance and turbulence, allowing for smoother fuel-air mixture intake and exhaust gas expulsion. Improved porting directly contributes to higher torque, better throttle response, and increased overall engine efficiency.

Methods of Cylinder Head Porting

Cylinder head porting methods include hand-porting using abrasive tools, CNC porting for precise material removal, and flow testing with a flow bench to optimize airflow efficiency. Wet sanding enhances surface finish to reduce airflow resistance, while bead blasting removes casting imperfections. Computational fluid dynamics (CFD) simulations assist in designing optimal port shapes for improved volumetric efficiency and horsepower gains.

Tools Required for Cylinder Head Porting

Cylinder head porting requires precision tools such as a die grinder, carbide burrs, and sanding rolls to effectively reshape and smooth intake and exhaust ports. Measuring instruments like calipers and flow benches are essential for ensuring optimal port size and surface finish to maximize airflow and engine performance. Proper safety equipment, including gloves and eye protection, is critical to prevent injury during the porting process.

Intake Porting Example: Increasing Airflow

Increasing airflow in automotive cylinder heads through intake porting significantly enhances engine performance by optimizing the shape and size of the intake ports. Smooth, streamlined port designs reduce turbulence and resistance, allowing a higher volume of air-fuel mixture to enter the combustion chamber efficiently. High-performance intake porting techniques, such as bowl blending and port matching, help maximize volumetric efficiency, resulting in improved throttle response and increased horsepower.

Exhaust Porting Example: Reducing Backpressure

Exhaust porting in the cylinder head involves reshaping and enlarging the exhaust ports to optimize the flow of exhaust gases and reduce backpressure. This process enhances engine efficiency by improving scavenging and increasing horsepower, especially noticeable in performance vehicles. CNC porting technology enables precise modifications, ensuring consistent flow dynamics and maximizing exhaust gas evacuation speed.

Common Mistakes in Cylinder Head Porting

Common mistakes in cylinder head porting include over-porting, which reduces air velocity and negatively impacts engine efficiency, and uneven port shaping that causes turbulent airflow and inconsistent combustion. Failing to match port sizes to the engine's displacement and cam profile often leads to a loss in power and throttle response. Inadequate blending of the port surface can create hotspots, increasing the risk of detonation and engine damage.

Flow Bench Testing for Porting Effectiveness

Flow bench testing measures the airflow efficiency through a cylinder head port by simulating engine conditions, helping engineers optimize port shapes for maximum volumetric efficiency. Precise porting enhances intake and exhaust flow, reducing turbulence and increasing engine performance and fuel efficiency. Data from flow bench testing guides modifications like smoothing surfaces and reshaping runners to improve combustion chamber filling and overall power output.

Real-World Results: Dyno Tests After Porting

Porting the cylinder head significantly improved airflow efficiency, resulting in a measurable increase in horsepower and torque during dyno tests. Real-world results showed a 10% boost in peak power output and a smoother torque curve across the mid-range RPM. These gains demonstrate the effectiveness of precision porting in enhancing engine performance and fuel efficiency.

Safety Precautions During Porting Process

During the porting process of a cylinder head, wearing protective gear such as safety goggles, gloves, and dust masks is crucial to prevent inhalation of harmful metal particles and protect against injury. Ensuring proper ventilation and using dust extraction systems reduces exposure to hazardous dust and fumes generated during grinding and sanding. Maintaining a clean work area and regularly inspecting tools further enhances safety by minimizing risks of accidents and equipment malfunctions.

example of porting in cylinder head Infographic

samplerz.com

samplerz.com