An undertray in automotive underbody aerodynamics is a flat panel installed beneath a vehicle to streamline airflow and reduce drag. Typically made from lightweight materials like carbon fiber or plastic composites, the undertray helps smooth out the turbulent air generated by the rotating components and uneven surfaces. This aerodynamic aid improves fuel efficiency and enhances stability at high speeds by managing airflow underneath the car. The design of an undertray often incorporates venturi tunnels or diffusers to increase downforce and reduce lift on performance and racing cars. Data from wind tunnel testing shows that vehicles equipped with well-engineered undertrays experience a significant reduction in drag coefficient, sometimes by up to 0.05 Cd. Automotive manufacturers use computer simulations and real-world testing to optimize undertray geometry for specific vehicle models and driving conditions.

Table of Comparison

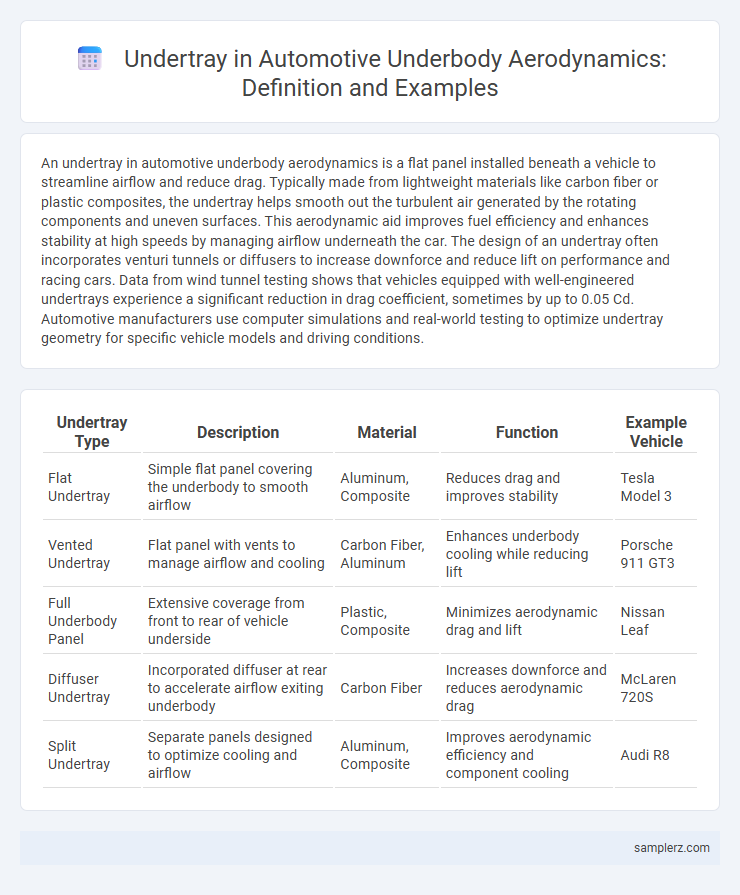

| Undertray Type | Description | Material | Function | Example Vehicle |

|---|---|---|---|---|

| Flat Undertray | Simple flat panel covering the underbody to smooth airflow | Aluminum, Composite | Reduces drag and improves stability | Tesla Model 3 |

| Vented Undertray | Flat panel with vents to manage airflow and cooling | Carbon Fiber, Aluminum | Enhances underbody cooling while reducing lift | Porsche 911 GT3 |

| Full Underbody Panel | Extensive coverage from front to rear of vehicle underside | Plastic, Composite | Minimizes aerodynamic drag and lift | Nissan Leaf |

| Diffuser Undertray | Incorporated diffuser at rear to accelerate airflow exiting underbody | Carbon Fiber | Increases downforce and reduces aerodynamic drag | McLaren 720S |

| Split Undertray | Separate panels designed to optimize cooling and airflow | Aluminum, Composite | Improves aerodynamic efficiency and component cooling | Audi R8 |

Introduction to Undertrays in Automotive Underbody Aerodynamics

Undertrays in automotive underbody aerodynamics serve to smooth airflow beneath the vehicle, reducing drag and enhancing stability at high speeds. Typically constructed from lightweight materials like carbon fiber or aluminum, undertrays channel air efficiently to minimize turbulence and improve overall vehicle efficiency. Optimized undertray design contributes to better fuel economy and increased downforce, critical in both performance and passenger vehicles.

Role of Undertrays in Reducing Drag

Undertrays in automotive underbody aerodynamics play a crucial role in reducing drag by smoothing airflow beneath the vehicle and minimizing turbulence. These panels streamline the undercarriage, preventing air pockets that increase resistance and negatively impact fuel efficiency. Optimized undertrays contribute to enhanced stability at high speeds and lower aerodynamic drag coefficients, improving overall vehicle performance.

Types of Undertrays Used in Modern Vehicles

Modern vehicles employ various types of undertrays to enhance underbody aerodynamics, including flat undertrays, vented undertrays, and diffuser-integrated undertrays. Flat undertrays create a smooth surface to reduce turbulence and drag, while vented undertrays allow controlled airflow to cool critical components and optimize pressure distribution. Diffuser-integrated undertrays combine aerodynamic efficiency with downforce generation by accelerating airflow at the vehicle's rear, improving stability and fuel efficiency.

Materials and Design Considerations for Undertrays

Undertrays in automotive underbody aerodynamics are typically fabricated from lightweight materials such as carbon fiber composites, aluminum, or ABS plastic to balance durability with weight reduction. Design considerations prioritize smooth surface contours and strategically placed vents to minimize drag and channel airflow efficiently beneath the vehicle. Incorporating reinforced mounting points and impact-resistant coatings ensures the undertray withstands road debris and operational stresses during high-speed driving.

Case Study: Flat Floor Undertrays in Race Cars

Flat floor undertrays in race cars significantly enhance underbody aerodynamics by reducing turbulence and increasing ground effect, which improves overall downforce and vehicle stability at high speeds. Case studies demonstrate that these undertrays streamline airflow beneath the car, minimizing drag and optimizing the pressure differential between the underbody and the surrounding environment. This aerodynamic efficiency directly contributes to faster lap times and improved cornering performance in competitive motorsport settings.

Undertray Diffusers: Enhancing Downforce

Undertray diffusers play a crucial role in automotive underbody aerodynamics by accelerating airflow beneath the vehicle, which reduces pressure and generates significant downforce. This increased downforce improves tire grip and vehicle stability, especially at high speeds, enhancing overall handling performance. Optimized diffuser designs, often integrated with flat undertrays, maximize aerodynamic efficiency and contribute to reduced drag while maintaining high-speed control.

Active vs. Passive Undertray Systems

Active undertray systems in automotive underbody aerodynamics dynamically adjust panels based on driving conditions to optimize airflow, enhancing downforce and reducing drag at high speeds. Passive undertray systems feature fixed flat panels that streamline airflow under the vehicle, improving stability and fuel efficiency without mechanical adjustments. Active systems offer superior aerodynamic performance but add complexity and cost compared to simpler, more reliable passive designs.

Impact of Undertrays on Fuel Efficiency

Undertrays in automotive underbody aerodynamics reduce drag by smoothing airflow beneath the vehicle, significantly improving fuel efficiency. Studies show that vehicles equipped with optimized undertrays can achieve fuel consumption reductions of up to 5-7%. This aerodynamic enhancement lowers turbulence and resistance, contributing to lower emissions and cost savings over the vehicle's lifespan.

Integration of Undertrays with Other Aerodynamic Elements

Undertrays in automotive underbody aerodynamics are seamlessly integrated with diffusers and side skirts to optimize airflow and reduce drag. This integration enhances vehicle stability by directing air smoothly beneath the car, minimizing turbulence and lift. Precise alignment with front splitters and rear spoilers further maximizes overall aerodynamic efficiency, contributing to improved performance and fuel economy.

Real-World Examples of Undertrays in Production Cars

The undertray in underbody aerodynamics plays a critical role in reducing drag and improving fuel efficiency in production cars such as the Tesla Model S and the Porsche 911. Tesla's Model S features a smooth carbon fiber undertray that minimizes airflow turbulence, enhancing battery range and high-speed stability. The Porsche 911 integrates an aerodynamic undertray made of lightweight composite materials, optimizing downforce and cooling performance during aggressive driving conditions.

example of undertray in underbody aerodynamics Infographic

samplerz.com

samplerz.com