A knock sensor is an essential component in modern automotive engines, designed to detect engine knocking or pinging caused by premature combustion. This sensor generates an electronic signal that the engine control unit (ECU) uses to adjust ignition timing and prevent damage. For example, the Bosch 0261231033 knock sensor is widely used in various engine models to optimize performance and protect internal components. This sensor operates by converting vibrations from engine knock into electrical signals, which are then processed by the ECU. In vehicles such as the Honda Civic and Toyota Camry, the knock sensor plays a critical role in maintaining fuel efficiency and engine durability. Accurate data from the knock sensor helps maintain smooth engine operation and reduces harmful emissions, ensuring compliance with environmental standards.

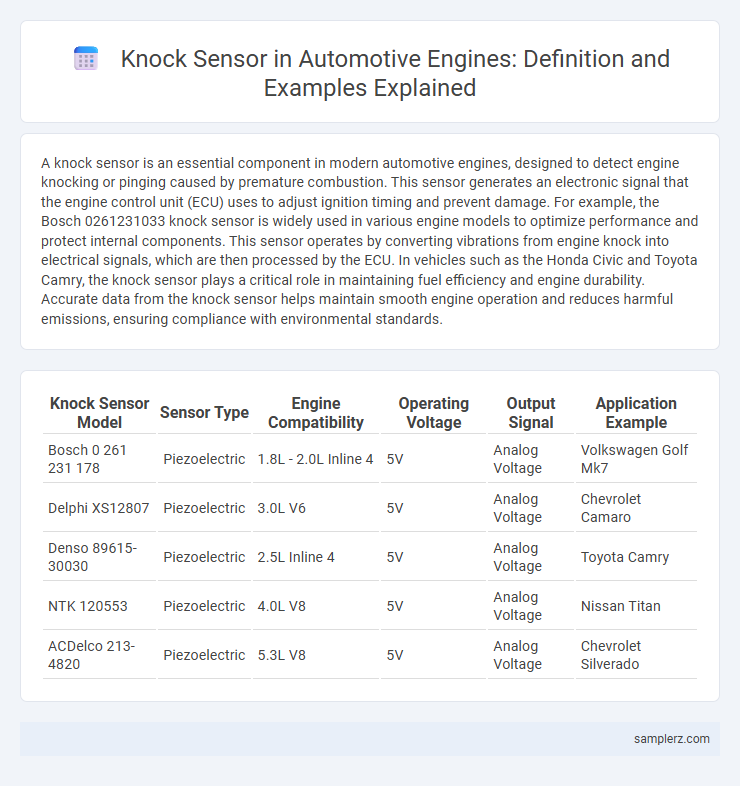

Table of Comparison

| Knock Sensor Model | Sensor Type | Engine Compatibility | Operating Voltage | Output Signal | Application Example |

|---|---|---|---|---|---|

| Bosch 0 261 231 178 | Piezoelectric | 1.8L - 2.0L Inline 4 | 5V | Analog Voltage | Volkswagen Golf Mk7 |

| Delphi XS12807 | Piezoelectric | 3.0L V6 | 5V | Analog Voltage | Chevrolet Camaro |

| Denso 89615-30030 | Piezoelectric | 2.5L Inline 4 | 5V | Analog Voltage | Toyota Camry |

| NTK 120553 | Piezoelectric | 4.0L V8 | 5V | Analog Voltage | Nissan Titan |

| ACDelco 213-4820 | Piezoelectric | 5.3L V8 | 5V | Analog Voltage | Chevrolet Silverado |

Introduction to Knock Sensors in Automotive Engines

Knock sensors in automotive engines detect abnormal combustion vibrations caused by engine knocking or pinging, preventing potential engine damage. These piezoelectric sensors convert pressure fluctuations into electrical signals that the engine control unit uses to adjust ignition timing. Efficient knock sensor integration enhances engine performance and fuel efficiency while reducing emissions.

How Knock Sensors Work: Basic Principles

A knock sensor detects engine knocking by sensing vibrations caused by abnormal combustion using a piezoelectric element that converts these vibrations into electrical signals. When the sensor detects knocking, it sends voltage signals to the engine control unit (ECU), which adjusts the ignition timing to prevent engine damage. This process ensures optimal engine performance, fuel efficiency, and reduced emissions by maintaining proper combustion timing.

Common Types of Knock Sensors Used in Engines

Common types of knock sensors used in automotive engines include piezoelectric sensors and accelerometer-based sensors, both designed to detect abnormal combustion vibrations. Piezoelectric knock sensors generate voltage signals in response to engine knock vibrations, enabling precise ignition timing adjustments. Accelerometer-based sensors provide enhanced sensitivity by measuring engine block vibrations, improving knock detection accuracy for better engine performance and efficiency.

Real-World Examples of Knock Sensors in Modern Vehicles

Tesla Model S utilizes a high-sensitivity knock sensor integrated into its electric motor control system to detect abnormal vibrations, improving combustion efficiency in its range-extender variant. The Honda Accord employs a piezoelectric knock sensor on its 1.5L turbocharged engine, enabling precise ignition timing adjustments to prevent engine knocking under various load conditions. BMW's B48 engine series incorporates a dual knock sensor configuration that monitors cylinder-specific vibrations, optimizing performance and reducing emissions through real-time data analysis.

Case Study: Knock Sensor Application in Toyota Engines

Toyota engines utilize knock sensors to detect engine knocking by monitoring vibrations and pressure changes within the combustion chamber. These sensors send real-time signals to the engine control unit (ECU), allowing precise ignition timing adjustments that enhance fuel efficiency and engine longevity. The implementation of knock sensors in Toyota models like the Camry and Corolla significantly reduces harmful detonation, improving overall performance and emissions compliance.

Impact of Faulty Knock Sensors on Engine Performance

A faulty knock sensor disrupts the engine's ability to detect abnormal combustion, leading to inefficient ignition timing and increased engine knocking. This malfunction results in reduced fuel efficiency, elevated emissions, and potential long-term damage to pistons and valves. Detecting sensor failure early helps maintain optimal engine performance and prevents costly repairs.

How OEMs Integrate Knock Sensors for Enhanced Efficiency

OEMs integrate knock sensors directly onto the engine block or cylinder head to monitor combustion vibrations in real-time, enabling precise ignition timing adjustments. Advanced knock sensors utilize piezoelectric materials to detect abnormal knocking frequencies, allowing the engine control unit (ECU) to optimize fuel-air mixture and improve engine efficiency. This integration reduces engine knock, lowers emissions, and enhances overall vehicle performance by ensuring smoother combustion cycles.

Diagnosing Knock Sensor Issues: Symptoms and Solutions

Engine misfires, reduced fuel efficiency, and persistent knocking noises indicate potential knock sensor malfunctions in automotive engines. Diagnostic tools detect abnormal vibrations and irregular ignition timing to pinpoint sensor failures. Replacing faulty knock sensors and ensuring proper wiring connections restore engine performance and prevent long-term damage.

Advances in Knock Sensor Technology for Automotive Applications

Modern knock sensors utilize piezoelectric materials to detect engine vibrations caused by pre-ignition, allowing real-time adjustment of ignition timing for optimal performance. Advanced sensor designs incorporate integrated microelectromechanical systems (MEMS) to enhance sensitivity and reduce noise interference, improving combustion efficiency and reducing emissions. These innovations enable precise engine control, contributing to improved fuel economy and compliance with stringent emission regulations.

Choosing the Right Knock Sensor for Your Engine Model

Selecting the appropriate knock sensor for your engine model ensures precise detection of engine knocking, optimizing performance and preventing damage. Engine-specific sensors vary in sensitivity and frequency range, matching the ignition timing and combustion characteristics unique to each model. Installing a compatible knock sensor enhances fuel efficiency, reduces emissions, and extends engine lifespan.

example of knock sensor in engine Infographic

samplerz.com

samplerz.com