A locknut in steering systems is a specialized fastener designed to secure components like tie rod ends and steering linkages, preventing loosening due to vibrations. It features a unique design, such as a nylon insert or deformed threads, which grips the mating threads firmly under dynamic loads. This ensures the steering assembly maintains alignment and improves vehicle safety by reducing the risk of steering failure. Tie rod locknuts are commonly used in passenger cars and commercial trucks to maintain precise steering geometry. These locknuts are typically made from high-strength steel with corrosion-resistant coatings to withstand harsh automotive environments. Proper installation torque is critical to ensure optimal clamping force and to avoid loosening during operation, thereby enhancing the reliability of the steering system.

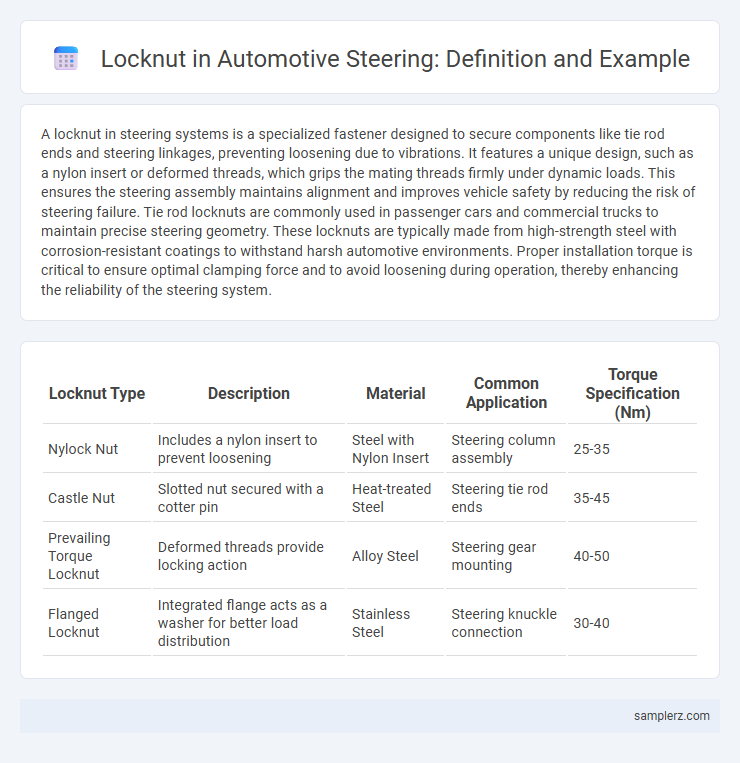

Table of Comparison

| Locknut Type | Description | Material | Common Application | Torque Specification (Nm) |

|---|---|---|---|---|

| Nylock Nut | Includes a nylon insert to prevent loosening | Steel with Nylon Insert | Steering column assembly | 25-35 |

| Castle Nut | Slotted nut secured with a cotter pin | Heat-treated Steel | Steering tie rod ends | 35-45 |

| Prevailing Torque Locknut | Deformed threads provide locking action | Alloy Steel | Steering gear mounting | 40-50 |

| Flanged Locknut | Integrated flange acts as a washer for better load distribution | Stainless Steel | Steering knuckle connection | 30-40 |

Introduction to Locknuts in Automotive Steering

Locknuts in automotive steering are specialized fasteners designed to secure steering components and resist loosening caused by vibrations and torque fluctuations. Common types include nylon insert locknuts and prevailing torque locknuts, both engineered to maintain tightness under dynamic driving conditions. The use of locknuts enhances steering system reliability, improves safety, and reduces maintenance frequency by preventing component disengagement.

Importance of Locknuts for Steering Safety

Locknuts in steering systems secure critical components, preventing loosening caused by vibrations or road shocks. High-quality locknuts maintain alignment and structural integrity, directly contributing to precise steering control and overall vehicle safety. Their reliability reduces maintenance needs and the risk of steering failure, ensuring driver confidence and accident prevention.

Common Types of Locknuts Used in Steering Systems

Common types of locknuts used in steering systems include nylon-insert locknuts, prevailing torque locknuts, and castellated locknuts. Nylon-insert locknuts feature a polymer ring that resists loosening due to vibration, commonly applied in tie rod ends. Castellated locknuts are paired with cotter pins for secure locking, frequently used in ball joints to ensure safety in dynamic steering conditions.

Example: Jam Nut in Steering Linkage

A jam nut in steering linkage serves as a locknut that prevents loosening in critical connections between tie rods and steering arms. By tightening the jam nut against the main adjusting nut, it secures steering alignment and enhances vehicle safety. This simple yet effective component ensures precise steering response by maintaining proper tension under vibration and dynamic driving conditions.

Example: Slotted Nut with Cotter Pin in Tie Rod Ends

A slotted nut with a cotter pin is commonly used in tie rod ends to secure the steering linkage, ensuring a firm connection that prevents rotation and loosening under dynamic loads. This locknut design enhances safety by allowing the cotter pin to pass through aligned slots in the nut and a drilled hole in the bolt, effectively locking the assembly in place. Such assemblies are critical for maintaining precise steering control and vehicle stability in automotive steering systems.

Example: Nylon Insert Locknut on Steering Shaft

The nylon insert locknut on a steering shaft provides reliable vibration resistance and secures the steering components firmly in place, preventing loosening over time. This type of locknut features a nylon collar that creates friction against the threads, ensuring stability under dynamic driving conditions. Its application in automotive steering assemblies enhances safety by maintaining consistent steering precision and minimizing maintenance needs.

Application of Staked Locknuts in Steering Columns

Staked locknuts are crucial in steering columns to prevent loosening under vibration and torque, ensuring secure fastening of the steering shaft to the steering gear. Their mechanical deformation provides a reliable locking mechanism, maintaining consistent steering performance and safety. This application is vital in automotive design to enhance driver control and prevent potential steering failures.

Locknut Usage in Power Steering Rack Assemblies

Locknuts in power steering rack assemblies secure the tie rod ends to the steering rack, preventing loosening under constant vibration and torque. High-grade steel locknuts with nylon inserts are commonly used to maintain tight clamping force, enhancing steering precision and safety. Proper installation of locknuts helps ensure reliable vehicle handling and minimizes maintenance needs.

Steering U-Joint Locknut Example and Function

The Steering U-Joint Locknut secures the universal joint to the steering shaft, preventing loosening under vibrations and torque stresses common in automotive steering systems. This locknut maintains precise alignment of the steering components, ensuring responsive and stable vehicle handling. High-strength materials and thread-locking features optimize durability and safety in demanding driving conditions.

Maintenance Tips for Locknuts in Steering Mechanisms

Regular inspection of locknuts in steering mechanisms is essential to prevent loosening that could compromise vehicle control and safety. Applying appropriate torque specifications and using thread-locking compounds during reassembly ensures secure fastening and reduces the risk of vibration-induced movement. Lubricating locknuts with anti-corrosive agents helps prevent rust and extends the lifespan of steering components in various driving conditions.

example of locknut in steering Infographic

samplerz.com

samplerz.com