In the automotive industry, a tramp in the axle refers to a rapid oscillation or shaking of the axle shaft, commonly caused by imbalance or misalignment. This phenomenon often results from uneven tire wear, bent axle components, or damaged wheel bearings, which disrupt the smooth rotation of the axle. Such vibrations can lead to increased wear on suspension parts and negatively impact vehicle handling and safety. Tramp in the axle is frequently observed in vehicles with high mileage or those subjected to rough terrain, where physical stress compromises axle integrity. Automotive technicians use diagnostic tools like vibration analyzers and wheel alignment systems to identify the source of the tramp effect. Corrective actions include wheel balancing, axle straightening, or replacing worn components to restore optimal drive axle function and enhance vehicle performance.

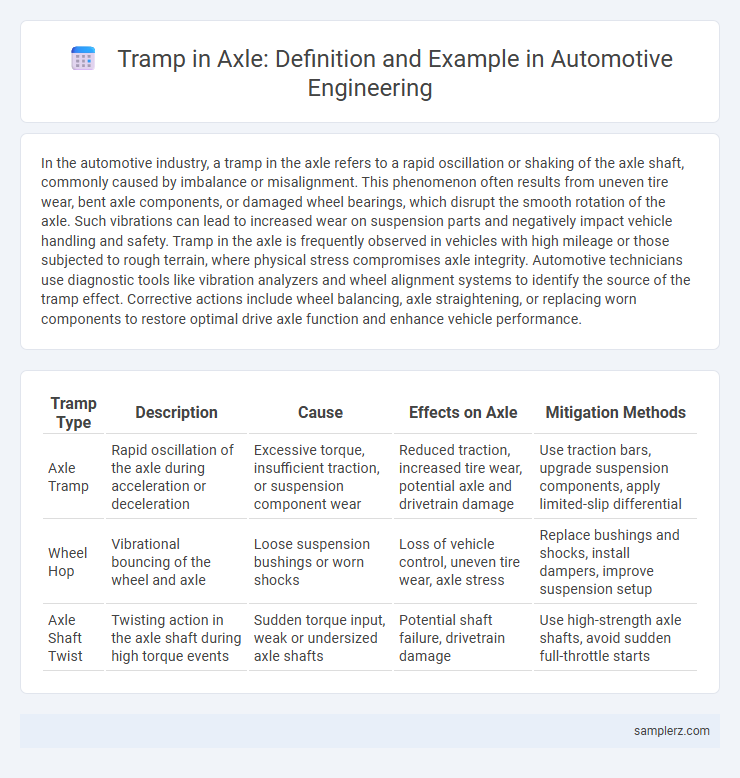

Table of Comparison

| Tramp Type | Description | Cause | Effects on Axle | Mitigation Methods |

|---|---|---|---|---|

| Axle Tramp | Rapid oscillation of the axle during acceleration or deceleration | Excessive torque, insufficient traction, or suspension component wear | Reduced traction, increased tire wear, potential axle and drivetrain damage | Use traction bars, upgrade suspension components, apply limited-slip differential |

| Wheel Hop | Vibrational bouncing of the wheel and axle | Loose suspension bushings or worn shocks | Loss of vehicle control, uneven tire wear, axle stress | Replace bushings and shocks, install dampers, improve suspension setup |

| Axle Shaft Twist | Twisting action in the axle shaft during high torque events | Sudden torque input, weak or undersized axle shafts | Potential shaft failure, drivetrain damage | Use high-strength axle shafts, avoid sudden full-throttle starts |

Understanding Tramp in Automotive Axles

Tramp in automotive axles refers to the oscillatory motion or hopping of the drive axle under acceleration or braking, often caused by excessive torque and suspension system dynamics. This condition leads to reduced traction, accelerated tire and drivetrain wear, and can impact vehicle stability. Effective diagnosis involves inspecting axle components, suspension bushings, and torque arm conditions to mitigate tramp and maintain optimal vehicle performance.

Common Causes of Axle Tramp

Axle tramp commonly occurs due to worn or damaged suspension components such as bushings, control arms, or shocks that fail to properly control axle movement. Incorrect or loose U-bolts and leaf spring issues can also contribute to axle tramp by allowing excessive axle wrap under acceleration. High torque loads combined with insufficient damping often result in the characteristic hopping or jerking motion associated with axle tramp in trucks and performance vehicles.

Symptoms of Axle Tramp in Vehicles

Axle tramp in vehicles is characterized by rapid, uncontrolled oscillations of the drive axle under heavy acceleration, causing a noticeable shudder or vibration in the chassis. Common symptoms include a rhythmic clunking noise, reduced traction, and uneven tire wear, which directly affect vehicle stability and handling. Drivers may also experience difficulty maintaining consistent speed as the axle movement disrupts power delivery and suspension performance.

Real-World Examples of Axle Tramp

Axle tramp commonly occurs in high-performance drag racing where excessive torque causes the rear axle to oscillate uncontrollably, leading to loss of traction and potential damage to suspension components. In heavy-duty trucks, axle tramp can result from uneven road surfaces combined with worn-out leaf springs, causing vibrations that reduce vehicle stability and accelerate tire wear. Off-road vehicles frequently encounter axle tramp during rapid acceleration over rough terrain, highlighting the need for reinforced axles and upgraded traction control systems to maintain optimal performance.

The Impact of Tramp on Vehicle Stability

Axle tramp, characterized by rapid oscillations of the axle under acceleration or braking, significantly compromises vehicle stability by causing uneven tire contact with the road surface. This phenomenon increases vibrations transmitted to the chassis, leading to reduced traction and impaired steering responsiveness. Mitigating axle tramp through suspension tuning and traction control systems enhances overall vehicular control and safety during dynamic driving conditions.

Case Study: Tramp Occurrence in Heavy Trucks

Tramp in the axle of heavy trucks often results from uneven torque distribution and worn suspension components, leading to oscillations that compromise vehicle stability and increase tire wear. A case study analyzing a fleet of Class 8 trucks revealed that tramp frequency peaked under high load conditions during acceleration, correlating with axle misalignment and suboptimal shock absorber performance. Implementing upgraded dampers and routine axle inspections reduced tramp incidents by 40%, enhancing both safety and operational efficiency.

Tramp vs. Other Axle Vibrations

Tramp in axle refers to high-frequency, oscillating vibrations caused by uneven torque transfer or worn U-joints, leading to jerky motion and increased wear. Unlike other axle vibrations such as imbalance or misalignment, tramp specifically results from torque fluctuations during acceleration or deceleration cycles. Identifying tramp is crucial for improving drivetrain performance and preventing premature damage in automotive axles.

Diagnosing Tramp in Live and Dead Axles

Tramp in live and dead axles manifests as rapid, uncontrollable vertical wheel motion caused by irregular torque or uneven load distribution. Diagnosing axle tramp involves inspecting suspension components, checking for worn bushings, and analyzing tire wear patterns to identify the source of oscillation. Using vibration analysis tools and axle load sensors enhances accuracy in pinpointing specific causes of tramp in both live and dead axle configurations.

Preventive Measures to Avoid Axle Tramp

Axle tramp can be effectively prevented by upgrading to heavy-duty suspension components such as high-performance shocks and leaf springs that absorb and dissipate torsional forces. Regularly checking and maintaining proper torque settings on axle U-bolts and ensuring balanced tire pressure reduces stress concentrations that contribute to tramp. Implementing traction-enhancing devices like traction bars or ladder bars stabilizes the axle during acceleration, minimizing unwanted axle movement and vibration.

Solutions and Repairs for Axle Tramp Issues

Axle tramp, a common issue in performance and heavy-duty vehicles, can be effectively addressed through solutions such as upgrading to heavy-duty leaf springs or installing traction bars to stabilize axle movement. Repair techniques often involve reinforcing the suspension system and replacing worn-out bushings or shocks to reduce excessive axle oscillation and improve traction. Implementing these strategies results in enhanced vehicle stability, reduced tire wear, and optimized power transfer during acceleration.

example of tramp in axle Infographic

samplerz.com

samplerz.com