In the automotive industry, a biscuit in a torque converter refers to a small, resilient component used to cushion and connect parts within the torque converter assembly. This element helps dampen vibrations and absorb shock, enhancing the smooth transmission of power from the engine to the drivetrain. Typically made from durable rubber or composite materials, the biscuit plays a crucial role in improving the torque converter's performance and longevity. Torque converters with biscuits are commonly found in automatic transmissions, where precise control of torque transfer is essential for optimal vehicle operation. The biscuit ensures efficient torque multiplication by maintaining proper alignment and reducing wear between the stator and turbine components. Automotive engineers design biscuits to withstand high temperatures and mechanical stress, contributing to the overall reliability of the transmission system.

Table of Comparison

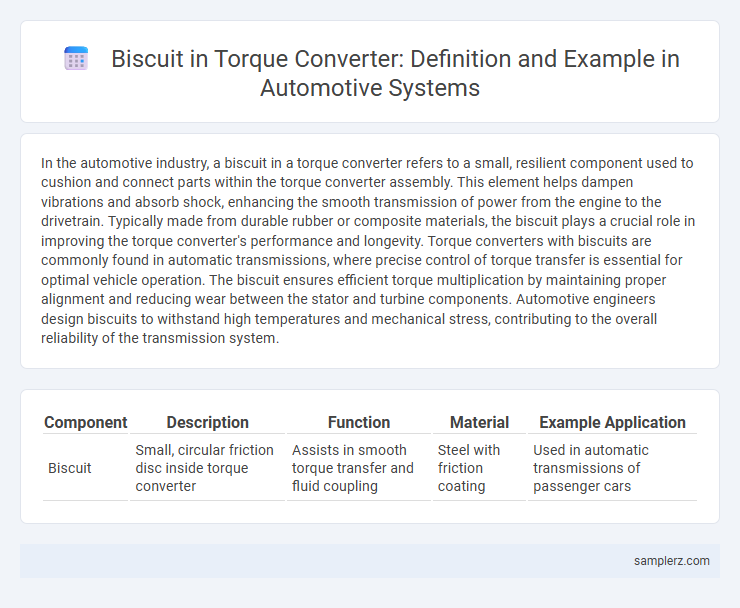

| Component | Description | Function | Material | Example Application |

|---|---|---|---|---|

| Biscuit | Small, circular friction disc inside torque converter | Assists in smooth torque transfer and fluid coupling | Steel with friction coating | Used in automatic transmissions of passenger cars |

Understanding the "Biscuit" in Torque Converters

The "biscuit" in a torque converter refers to a thin, disc-shaped component typically made from friction material, positioned between the impeller and turbine. This element plays a crucial role in modulating torque transfer and reducing slippage during gear shifts, enhancing transmission efficiency. Understanding the biscuit's material composition and placement helps automotive engineers optimize powertrain performance and improve vehicle fuel economy.

Functions of the Biscuit Component in Automotive Torque Converters

The biscuit in automotive torque converters serves as a cushion that dampens torsional vibrations, enhancing power transmission smoothness between the engine and transmission. This component absorbs shock loads during gear shifts, reducing noise and wear on drivetrain parts. By improving vibration isolation, the biscuit contributes to extended torque converter durability and optimized vehicle performance.

Common Materials Used for Biscuits in Torque Converters

Biscuits in torque converters are commonly made from steel and aluminum alloys due to their high strength and resistance to wear under extreme pressure. These materials ensure efficient energy transfer and durability within the torque converter's clutch mechanism. Advanced composites and heat-treated metals are also utilized to enhance thermal stability and reduce friction losses in high-performance automotive applications.

Key Examples of Biscuit Applications in Torque Converter Design

Key examples of biscuit applications in torque converter design include the use of multi-layer friction biscuits that optimize torque transfer efficiency while minimizing heat generation. These biscuits, typically made from composite materials like carbon fiber or organic resins, provide enhanced durability and improved clutch engagement under high-stress conditions. Integrating biscuit elements into the lock-up clutch system significantly reduces slippage, resulting in better fuel economy and smoother vehicle acceleration.

How the Biscuit Impacts Torque Converter Performance

The biscuit in a torque converter acts as a crucial component that regulates hydraulic pressure and fluid flow within the unit, directly influencing torque multiplication efficiency. Its material composition and precise fit affect heat dissipation and durability, ensuring consistent performance under varying engine loads. Optimizing biscuit design enhances the smoothness of power transmission and reduces energy losses, leading to improved fuel efficiency and overall vehicle responsiveness.

Diagnosing Biscuit Failure in Torque Converters

Biscuit failure in torque converters often manifests through symptoms such as shuddering during acceleration, increased transmission temperature, and erratic gear shifts. Diagnosing this issue involves inspecting for compromised friction material on the clutch bicycle, checking for contamination or wear, and conducting stall speed tests to identify torque transfer inefficiencies. Early detection of biscuit degradation prevents severe transmission damage and ensures optimal vehicle performance.

Signs of a Worn or Damaged Torque Converter Biscuit

Worn or damaged torque converter biscuits often exhibit symptoms such as excessive shuddering or vibration during gear shifts, indicating compromised fluid coupling efficiency. Drivers may also notice delayed acceleration or slipping gears, caused by the biscuit's inability to maintain proper torque transfer. Unusual noises like rattling or grinding from the torque converter housing further signify internal component deterioration requiring immediate inspection.

Steps for Replacing the Biscuit in a Torque Converter

Start by draining the transmission fluid and removing the torque converter from the vehicle to access the biscuit. Carefully extract the old biscuit, ensuring no debris falls into the housing, then install the new biscuit by aligning it properly within the torque converter assembly. Reassemble the torque converter, refill with the recommended transmission fluid, and test for proper operation to complete the replacement process.

Innovations in Biscuit Technology for Torque Converters

Innovations in biscuit technology for torque converters have significantly enhanced energy efficiency and thermal management by utilizing advanced composite materials that reduce weight while maintaining durability. The integration of high-performance polymers and precision-engineered geometries improves the torque transfer ratio and minimizes slippage, directly contributing to smoother power delivery and fuel economy. Emerging designs also incorporate nano-coatings to resist wear and corrosion, extending component lifespan and reducing maintenance costs in modern automotive drivetrains.

Frequently Asked Questions About Biscuits in Automotive Torque Converters

Biscuits in automotive torque converters refer to the friction plates that improve the transmission's efficiency by engaging and disengaging clutch packs. These components are essential for smooth power transfer between the engine and the transmission, reducing slippage and enhancing performance. Common FAQs address their material composition, lifespan, and maintenance requirements to prevent torque converter failure.

example of biscuit in torque converter Infographic

samplerz.com

samplerz.com