A dog ring in a gearbox is a crucial mechanical component used to engage gears in manual transmissions. It consists of a slotted ring that fits around the gear shaft, allowing the gears to lock together for smooth power transfer. This part improves the precision and responsiveness of gear shifts, enhancing overall vehicle performance. Dog rings are typically made of hardened steel to withstand high torque and wear during gear engagement. They work in conjunction with synchronizer rings to reduce gear clash and ensure seamless transitions. The design and quality of dog rings directly impact the durability and efficiency of automotive gearboxes.

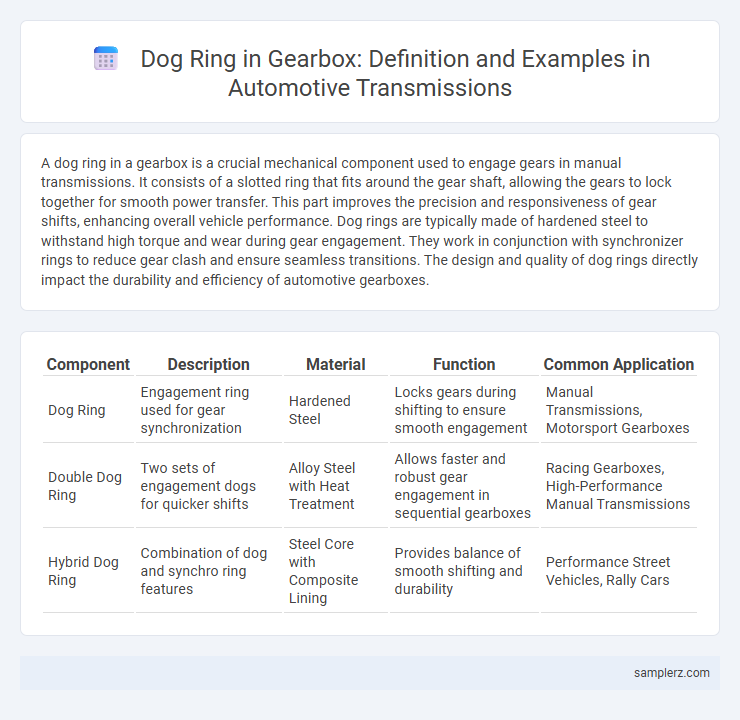

Table of Comparison

| Component | Description | Material | Function | Common Application |

|---|---|---|---|---|

| Dog Ring | Engagement ring used for gear synchronization | Hardened Steel | Locks gears during shifting to ensure smooth engagement | Manual Transmissions, Motorsport Gearboxes |

| Double Dog Ring | Two sets of engagement dogs for quicker shifts | Alloy Steel with Heat Treatment | Allows faster and robust gear engagement in sequential gearboxes | Racing Gearboxes, High-Performance Manual Transmissions |

| Hybrid Dog Ring | Combination of dog and synchro ring features | Steel Core with Composite Lining | Provides balance of smooth shifting and durability | Performance Street Vehicles, Rally Cars |

Understanding the Function of a Dog Ring in Gearboxes

A dog ring in a gearbox serves as a critical component for engaging and disengaging gears by physically locking them into place, ensuring smooth power transmission between the engine and the drivetrain. Its design allows quick gear shifts without synchromesh, commonly found in racing or heavy-duty automotive transmissions. By facilitating direct mechanical coupling, the dog ring enhances gear engagement efficiency and reduces wear on internal gearbox components.

Key Components of a Dog Ring Mechanism

A dog ring in a gearbox consists primarily of the dog ring itself, which features engagement slots or teeth designed to mesh with corresponding dog teeth on the gear hubs, enabling positive gear engagement without slipping. Key components include the dog teeth for locking gears, the ring body housing these teeth, and the shift blocker mechanism that prevents accidental engagement. This system ensures seamless power transfer and precise gear changes within manual transmissions used in automotive applications.

How Dog Rings Enable Faster Gear Shifts

Dog rings in gearboxes provide precise engagement of gears by locking them directly to the shaft, eliminating the need for synchronizers and reducing shift time. Their robust design allows instant gear meshing under high torque, which is crucial for performance vehicles requiring rapid acceleration and deceleration. The mechanical efficiency of dog rings minimizes power loss during shifts, enabling faster and smoother gear transitions in automotive transmissions.

Dog Ring vs Synchromesh Gearbox: Main Differences

Dog rings in gearboxes provide direct mechanical engagement for rapid gear shifts, enhancing performance in racing or off-road vehicles. Synchromesh gearboxes utilize synchronizer rings to match gear speeds before engagement, ensuring smooth and quiet shifts suitable for everyday driving. The main difference lies in dog rings offering quick, durable shifts with potential gear clash, while synchromesh prioritizes comfort and ease of use at lower RPMs.

Real-World Applications of Dog Rings in Motorsports

Dog rings in motorsports gearboxes provide quick and precise gear engagement, essential for high-performance racing vehicles. These components enable rapid shifting under extreme conditions, minimizing power loss and enhancing acceleration on circuits. Real-world applications include rally cars and Formula racing, where the durability and reliability of dog rings contribute significantly to competitive advantage.

Advantages of Using Dog Rings in Performance Vehicles

Dog rings in performance vehicle gearboxes enable rapid gear shifts by providing a direct mechanical engagement between gears, minimizing shift time and enhancing acceleration. They offer increased durability under high torque conditions, reducing wear compared to synchromesh systems. This robust engagement improves overall drivetrain efficiency and vehicle responsiveness on the track or during spirited driving.

Maintenance Tips for Dog Ring Gearboxes

Regular lubrication with high-quality gear oil prevents wear and ensures smooth engagement of dog ring gearboxes. Inspect dog rings and selector forks periodically for signs of chips or excessive wear to avoid transmission malfunction. Timely replacement of damaged components enhances gearbox lifespan and maintains optimal shifting performance.

Common Issues and Wear Patterns in Dog Rings

Dog rings in automotive gearboxes commonly exhibit wear patterns such as chipping and rounded edges due to repeated engagement under high torque conditions. Common issues include difficulty in gear shifting and increased noise, often caused by metal fatigue and improper lubrication. Monitoring these wear patterns is crucial for preventing gearbox failure and ensuring smooth transmission performance.

Upgrading to a Dog Ring Gearbox: What to Consider

Upgrading to a dog ring gearbox enhances shifting speed and durability by utilizing interlocking teeth that reduce gear slippage, essential for high-performance automotive applications. Consider compatibility with existing transmission components, material quality, and the impact on vehicle drivability, including the need for precise clutch engagement. Proper installation and tuning ensure the dog ring gearbox delivers optimal power transfer and longevity under demanding driving conditions.

Case Study: Dog Ring Gearboxes in Touring Cars

Dog ring gearboxes in touring cars demonstrate exceptional durability and rapid gear engagement, crucial for high-performance racing conditions. Case studies reveal that the precision-machined dog rings minimize gear clash and enable seamless power transfer, enhancing acceleration and lap times. Optimized materials like heat-treated steel improve wear resistance and extend the gearbox lifespan under intense track stresses.

example of dog ring in gearbox Infographic

samplerz.com

samplerz.com