Casting flash in an engine block refers to the excess thin layer of metal that forms along the parting line or seams of the mold during the casting process. This defect occurs when molten metal leaks between the mold halves or cores, creating unwanted material that must be removed to ensure proper engine block assembly. Common locations for casting flash include the cylinder bores, water jackets, and deck surfaces of the engine block. The presence of casting flash can affect the engine block's dimensional accuracy, leading to issues such as improper sealing, coolant leaks, or interference with moving components. Manufacturers use precision machining and grinding techniques to remove the flash and restore the correct engine block dimensions. Detecting and controlling casting flash early in production improves engine performance and reduces scrap rates in automotive manufacturing.

Table of Comparison

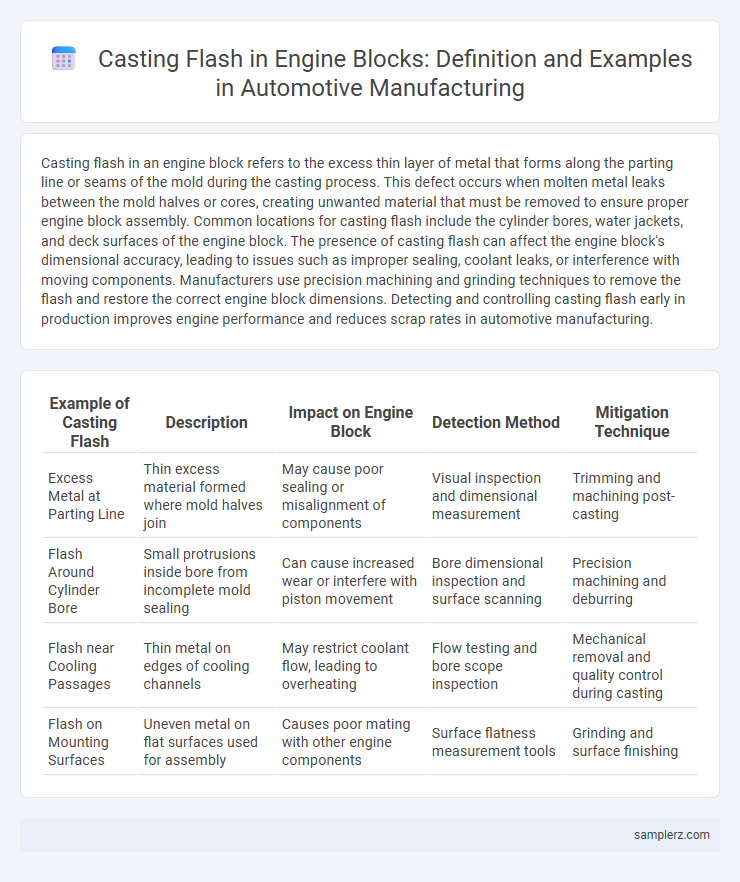

| Example of Casting Flash | Description | Impact on Engine Block | Detection Method | Mitigation Technique |

|---|---|---|---|---|

| Excess Metal at Parting Line | Thin excess material formed where mold halves join | May cause poor sealing or misalignment of components | Visual inspection and dimensional measurement | Trimming and machining post-casting |

| Flash Around Cylinder Bore | Small protrusions inside bore from incomplete mold sealing | Can cause increased wear or interfere with piston movement | Bore dimensional inspection and surface scanning | Precision machining and deburring |

| Flash near Cooling Passages | Thin metal on edges of cooling channels | May restrict coolant flow, leading to overheating | Flow testing and bore scope inspection | Mechanical removal and quality control during casting |

| Flash on Mounting Surfaces | Uneven metal on flat surfaces used for assembly | Causes poor mating with other engine components | Surface flatness measurement tools | Grinding and surface finishing |

Introduction to Casting Flash in Engine Blocks

Casting flash in engine blocks occurs when excess molten metal seeps out between the mold halves during the casting process, resulting in thin, unwanted metal protrusions along parting lines. This defect can interfere with the engine block's precision surfaces, affecting sealing and assembly of components such as cylinder heads and gaskets. Detecting and removing casting flash through machining or grinding is essential to maintain engine block integrity and performance.

Common Locations of Casting Flash in Engine Blocks

Casting flash in engine blocks commonly appears along parting lines where the mold halves meet, often resulting in thin, excess metal ridges. These flashes are frequently found around cylinder bores, deck surfaces, and main bearing saddles, areas critical to engine performance and sealing. Detecting and removing casting flash in these locations ensures proper component fitment, prevents oil or coolant leaks, and maintains optimal engine reliability.

Visual Characteristics of Casting Flash

Casting flash in engine blocks appears as thin, irregular protrusions along the parting lines and mating surfaces, often exhibiting rough edges and inconsistent thickness. These flashes result from molten metal seeping into the clearance between the mold halves during the casting process. Visually, casting flash can cause misalignment with adjoining components, negatively impacting the engine block's sealing surfaces and overall dimensional accuracy.

Impact of Casting Flash on Engine Performance

Casting flash on an engine block, characterized by excess material along mating surfaces, creates uneven sealing surfaces that lead to oil and coolant leaks. Such defects disrupt proper combustion chamber pressure, resulting in reduced engine efficiency and increased emissions. Addressing casting flash during manufacturing is crucial to ensure optimal engine performance, durability, and fuel economy.

Identification Techniques for Casting Flash

Casting flash in engine blocks is identified through visual inspection using magnification tools and enhanced lighting to detect excess material along mold parting lines. Advanced non-destructive testing methods like ultrasonic scanning and 3D surface laser profiling provide precise measurements of flash thickness and location. Implementing these identification techniques ensures improved quality control and reduces the risk of engine block defects impacting performance.

Causes of Casting Flash During Engine Block Production

Casting flash in engine block production occurs due to molten metal leaking between the parting surfaces of the mold during the casting process. Improper mold alignment, excessive metal pouring pressure, and worn or damaged mold surfaces contribute significantly to the formation of casting flash. Controlling these factors through precise mold maintenance and optimized pouring parameters minimizes defects and enhances engine block quality.

Methods for Removing Casting Flash

Casting flash on an engine block, often appearing as thin excess metal along parting lines, can be removed through several effective methods. Mechanical techniques such as grinding and machining provide precise removal of flash, ensuring smooth surfaces and proper fitment of engine components. Advanced methods like abrasive blasting and robotic trimming enhance efficiency and consistency while minimizing damage to critical engine block features.

Effects of Unremoved Flash on Engine Durability

Unremoved casting flash on an engine block creates uneven surfaces that lead to poor sealing and increased wear in critical engine components. This results in oil leaks, reduced compression, and accelerated corrosion, drastically diminishing overall engine durability. Persistent flash defects can cause premature engine failure due to compromised structural integrity and improper coolant flow.

Quality Control Processes to Minimize Casting Flash

Casting flash in an engine block, a thin excess layer of metal that forms along the parting line during the casting process, can compromise engine performance and durability. Rigorous quality control processes such as precise mold alignment, consistent metal temperature monitoring, and automated flash detection systems are crucial for minimizing casting flash defects. Implementing real-time inspection techniques using machine vision and sensor technology enhances defect identification, ensuring higher engine block integrity and compliance with automotive industry standards.

Real-World Examples of Casting Flash in Engine Block Manufacturing

Casting flash in engine block manufacturing often appears as thin, excess material along the parting line of the mold, commonly seen around cylinder bores and coolant passages. Real-world examples include misaligned mold halves in high-volume production causing flash that affects the engine block's sealing surfaces and dimensional accuracy, resulting in leaks or assembly issues. Correcting flash requires precise mold maintenance, quality inspection protocols, and sometimes secondary machining to ensure engine block integrity.

example of casting flash in engine block Infographic

samplerz.com

samplerz.com