A dogbone mount in automotive applications refers to a small, rigid component designed to reduce engine vibrations and movement by connecting the engine or transmission to the vehicle chassis. This mount typically features a solid metal rod with rubber or polyurethane bushings at each end, resembling a dog bone shape, which helps absorb shocks and maintain alignment during vehicle operation. Its primary function is to enhance ride comfort and prevent damage by stabilizing the drivetrain under various driving conditions. Manufacturers often install dogbone mounts in front-wheel-drive vehicles, securing the engine to the subframe to control torque induced movement. Data shows that effective dogbone mounts can reduce engine movement by up to 50%, resulting in improved powertrain stability and decreased noise, vibration, and harshness (NVH) levels. Automotive engineers select mounting materials and designs to optimize durability while maintaining flexibility for dynamic load variations encountered during acceleration, deceleration, and cornering.

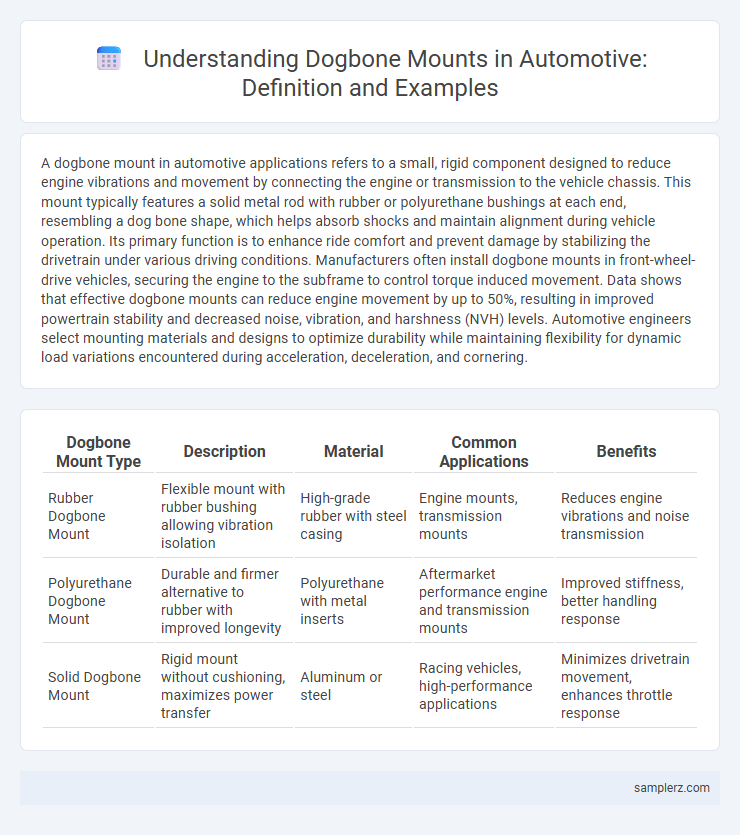

Table of Comparison

| Dogbone Mount Type | Description | Material | Common Applications | Benefits |

|---|---|---|---|---|

| Rubber Dogbone Mount | Flexible mount with rubber bushing allowing vibration isolation | High-grade rubber with steel casing | Engine mounts, transmission mounts | Reduces engine vibrations and noise transmission |

| Polyurethane Dogbone Mount | Durable and firmer alternative to rubber with improved longevity | Polyurethane with metal inserts | Aftermarket performance engine and transmission mounts | Improved stiffness, better handling response |

| Solid Dogbone Mount | Rigid mount without cushioning, maximizes power transfer | Aluminum or steel | Racing vehicles, high-performance applications | Minimizes drivetrain movement, enhances throttle response |

Introduction to Dogbone Mounts in Automotive Applications

Dogbone mounts in automotive applications serve as specialized engine or transmission mounts designed to reduce vibrations and enhance DRIVETRAIN stability. Typically fabricated from durable rubber bonded to metal, these mounts absorb TORQUE REACTIONS and minimize NVH (noise, vibration, and harshness), improving overall VEHICLE handling and comfort. Commonly found in HIGH-PERFORMANCE vehicles, dogbone mounts are crucial for maintaining ENGINE alignment and preventing excessive movement under load.

Understanding the Function of Dogbone Mounts

Dogbone mounts, commonly used in automotive suspension systems, serve to reduce engine and transmission vibrations transmitted to the chassis while maintaining drivetrain alignment. These mounts are designed with a rigid metal core surrounded by flexible rubber or polyurethane, allowing them to absorb torsional forces and restrict unwanted movement. By stabilizing the powertrain, dogbone mounts enhance vehicle handling, ride comfort, and reduce noise, vibration, and harshness (NVH) levels.

Common Types of Dogbone Mounts in Vehicles

Common types of dogbone mounts in vehicles include hydraulic mounts, rubber mounts, and solid mounts, each designed to reduce engine vibrations and improve drivetrain stability. Hydraulic dogbone mounts contain fluid-filled chambers that absorb engine motion more effectively, while rubber mounts utilize elastomeric materials to dampen vibrations. Solid dogbone mounts, typically made from metal, offer maximum rigidity and are often used in performance vehicles for enhanced power transfer and reduced engine movement.

Materials Used for Automotive Dogbone Mounts

Automotive dogbone mounts commonly utilize materials such as natural rubber and polyurethane, chosen for their superior vibration damping and durability. Some high-performance applications employ reinforced compounds or elastomer blends to enhance load-bearing capacity and resistance to wear. The selection of materials directly impacts ride comfort, noise reduction, and engine stability in vehicle operation.

Key Advantages of Dogbone Mounts in Engine Systems

Dogbone mounts in engine systems reduce torsional vibrations and improve powertrain stability by absorbing rotational energy between the engine and chassis. Their compact design enhances vehicle NVH (noise, vibration, and harshness) performance, leading to smoother acceleration and reduced drivetrain shock. This mount type also extends component lifespan by minimizing stress on engine brackets and transmission supports.

Example: Dogbone Mount in Volkswagen and Audi Models

The dogbone mount in Volkswagen and Audi models, such as the VW Golf and Audi A4, plays a crucial role in stabilizing the engine by absorbing vibrations and minimizing torque fluctuations during acceleration and deceleration. This elastomeric engine mount connects the engine to the chassis, enhancing ride comfort and drivetrain durability. Its design optimizes force distribution, contributing to the smooth performance and longevity of these vehicles' powertrains.

Dogbone Mount Placement: Where They Are Installed

Dogbone mounts are strategically installed between the engine and the chassis or subframe to absorb vibrations and reduce noise, enhancing ride comfort. Commonly positioned near the transmission or engine block, these mounts stabilize the powertrain by limiting excessive movement during acceleration and deceleration. Proper dogbone mount placement is crucial for maintaining driveline alignment and preventing premature wear on engine components.

Signs of Failing Dogbone Mounts and Their Impact

Signs of failing dogbone mounts include excessive engine movement, noticeable vibrations, and clunking noises during acceleration or gear shifts. These symptoms lead to compromised drivetrain stability, increased wear on transmission components, and reduced overall vehicle performance. Early detection and replacement of worn dogbone mounts prevent costly damage and maintain smooth, efficient power delivery.

Aftermarket vs. OEM Dogbone Mounts: A Comparative Overview

Aftermarket dogbone mounts in automotive applications often offer enhanced durability and improved vibration isolation compared to OEM counterparts, utilizing advanced materials like polyurethane instead of standard rubber. OEM dogbone mounts prioritize factory specifications and compatibility, ensuring seamless integration and consistent performance aligned with the vehicle's original design parameters. Choosing between aftermarket and OEM dogbone mounts depends on factors such as desired ride quality, performance needs, and budget considerations.

Maintenance Tips for Prolonging Dogbone Mount Life

Regularly inspect the dogbone mount for cracks or excessive wear, focusing on rubber bushings to prevent premature failure. Apply appropriate lubricants to reduce friction and avoid corrosion, enhancing durability under engine vibrations. Replace the mount promptly if signs of deterioration appear to maintain optimal engine stability and prevent further damage.

example of dogbone in mount Infographic

samplerz.com

samplerz.com