Engine knock, also known as detonation or pinging, occurs when the air-fuel mixture in the combustion chamber ignites prematurely. This untimely ignition causes a knocking or pinging sound, which can be damaging to engine components over time. Knock sensors detect these vibrations and adjust the ignition timing to prevent further damage. A common example of knock is experienced during heavy acceleration or with lower octane fuel than required by the engine. Modern vehicles use electronic control units (ECUs) to monitor knock sensor data and optimize combustion timing. Persistent knock can lead to reduced engine performance, increased emissions, and long-term mechanical failure.

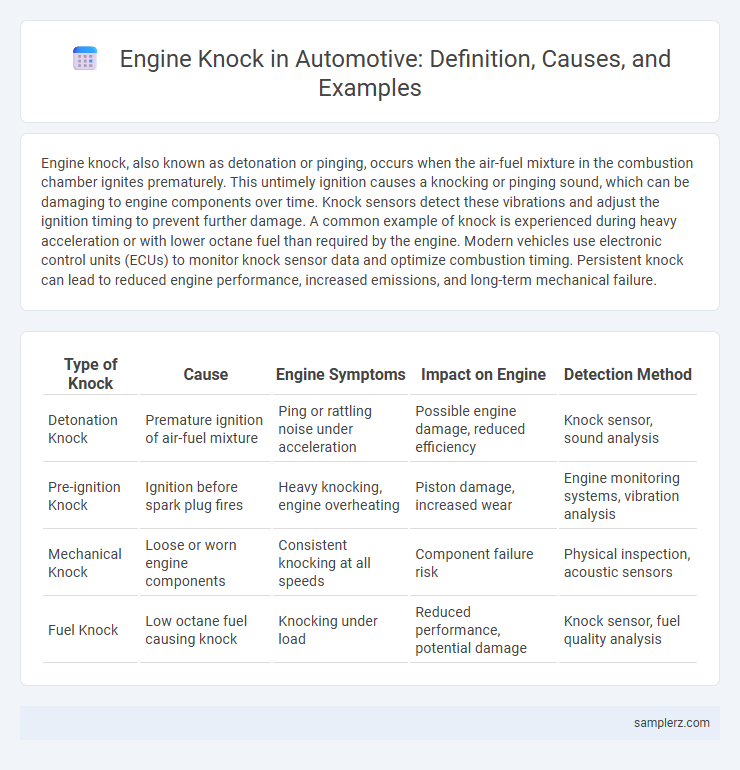

Table of Comparison

| Type of Knock | Cause | Engine Symptoms | Impact on Engine | Detection Method |

|---|---|---|---|---|

| Detonation Knock | Premature ignition of air-fuel mixture | Ping or rattling noise under acceleration | Possible engine damage, reduced efficiency | Knock sensor, sound analysis |

| Pre-ignition Knock | Ignition before spark plug fires | Heavy knocking, engine overheating | Piston damage, increased wear | Engine monitoring systems, vibration analysis |

| Mechanical Knock | Loose or worn engine components | Consistent knocking at all speeds | Component failure risk | Physical inspection, acoustic sensors |

| Fuel Knock | Low octane fuel causing knock | Knocking under load | Reduced performance, potential damage | Knock sensor, fuel quality analysis |

Understanding Engine Knock: Definition and Causes

Engine knock, also known as detonation, occurs when fuel-air mixture in the cylinder ignites prematurely or unevenly, causing a knocking or pinging sound. This phenomenon is typically caused by factors such as low-octane fuel, incorrect ignition timing, or excessive engine temperature, leading to damaging pressure spikes within the combustion chamber. Understanding engine knock is crucial for optimizing performance and preventing long-term damage to pistons, bearings, and cylinder walls.

Common Examples of Engine Knock in Modern Vehicles

Common examples of engine knock in modern vehicles include pre-ignition and detonation caused by low-octane fuel, carbon buildup inside the combustion chamber, and incorrect ignition timing. These issues lead to abnormal combustion, resulting in a metallic rattling noise and decreased engine performance. Sensors and advanced engine control units (ECUs) detect knock events to adjust fuel mixture and timing, preventing potential engine damage.

Symptoms that Indicate Engine Knock

Engine knock typically presents as a metallic pinging or knocking noise during acceleration or under heavy load, often accompanied by reduced power and decreased fuel efficiency. Drivers may notice rough idling or hesitation during throttle response, signaling abnormal combustion events. Persistent engine knock can lead to increased emissions and potential engine damage if not addressed promptly.

The Science Behind Engine Detonation

Engine knock occurs when air-fuel mixture in the combustion chamber detonates prematurely, causing shockwaves that generate a metallic banging noise. This abnormal combustion results from high cylinder pressure and temperature, often exacerbated by factors like low-octane fuel or advanced ignition timing. Understanding the molecular breakdown during autoignition reveals that rapid pressure rise disrupts the normal flame front, reducing engine efficiency and increasing wear on pistons and valves.

Impact of Low-Quality Fuel on Engine Knock

Low-quality fuel with low octane ratings causes early ignition in combustion chambers, resulting in engine knock that damages pistons and cylinder walls. This premature combustion increases engine temperature and pressure, accelerating wear and reducing overall engine performance. Consistent use of inferior fuel leads to costly repairs and diminished fuel efficiency in automotive engines.

Real-Life Case Studies of Engine Knocking

A real-life case study of engine knocking involved a 2018 Honda Civic where premature ignition of the air-fuel mixture caused persistent knocking, resulting in reduced engine efficiency and increased emissions. Diagnostic tests revealed low-octane fuel and carbon deposits on the pistons as primary contributors, leading to pre-ignition. After engine decarbonization and switching to higher-octane fuel, the knocking was eliminated and engine performance restored.

Engine Knock vs. Normal Combustion: Key Differences

Engine knock occurs when fuel-air mixture ignites prematurely or unevenly, causing sharp, metallic noises and potential damage to pistons and cylinders. Normal combustion involves a controlled ignition initiated by the spark plug at the optimal timing, ensuring smooth engine operation and maximum power output. Detecting knock early using knock sensors helps maintain engine performance and prevent costly repairs in automotive engines.

How Ignition Timing Affects Engine Knock

Ignition timing significantly influences engine knock by determining when the spark plug ignites the air-fuel mixture within the combustion chamber. Advancing the ignition timing causes the mixture to ignite too early, increasing cylinder pressure and temperature, which intensifies knocking. Retarding the timing allows combustion to occur later in the cycle, reducing knock risk but potentially decreasing engine power and efficiency.

Preventing and Addressing Engine Knock Issues

Engine knock, often caused by premature fuel combustion, leads to reduced performance and potential damage to pistons and cylinders. Preventing engine knock involves using high-octane fuel, maintaining proper ignition timing, and regularly inspecting spark plugs and air filters. Addressing persistent knock issues requires professional diagnostics to adjust fuel mixture or replace faulty sensors, ensuring optimal engine operation and longevity.

Consequences of Ignoring Engine Knock in Automobiles

Ignoring engine knock in automobiles can lead to severe damage such as piston cracking, cylinder wall scoring, and compromised ignition timing, resulting in reduced engine performance and fuel efficiency. Prolonged engine knocking increases the risk of catastrophic engine failure, demanding costly repairs or complete engine replacement. Early diagnosis and intervention are critical to prevent irreversible wear and maintain optimal engine longevity.

example of knock in engine Infographic

samplerz.com

samplerz.com