A drag link in an automotive steering mechanism is a crucial component that connects the pitman arm to the steering arm, facilitating the transfer of motion from the steering wheel to the wheels. It ensures precise steering control and maintains alignment by transmitting lateral forces effectively. Commonly found in conventional parallelogram steering systems, the drag link plays a vital role in heavy-duty vehicles and trucks. The drag link is typically constructed from high-strength steel to withstand the stress and torque generated during steering maneuvers. It features adjustable ends such as ball joints or tie rod ends for fine-tuning alignment and reducing wear. Proper maintenance and inspection of the drag link are essential to avoid steering play and ensure vehicle safety on the road.

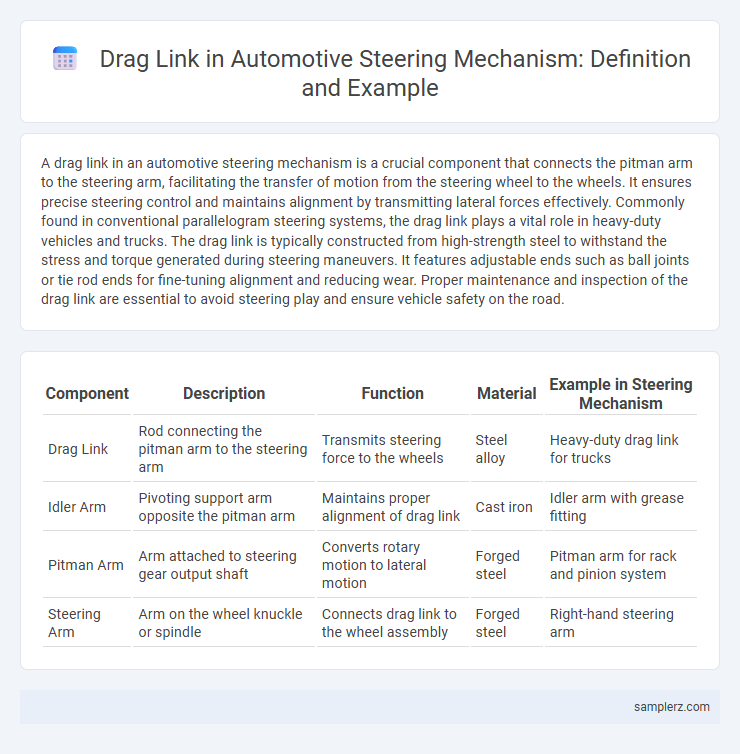

Table of Comparison

| Component | Description | Function | Material | Example in Steering Mechanism |

|---|---|---|---|---|

| Drag Link | Rod connecting the pitman arm to the steering arm | Transmits steering force to the wheels | Steel alloy | Heavy-duty drag link for trucks |

| Idler Arm | Pivoting support arm opposite the pitman arm | Maintains proper alignment of drag link | Cast iron | Idler arm with grease fitting |

| Pitman Arm | Arm attached to steering gear output shaft | Converts rotary motion to lateral motion | Forged steel | Pitman arm for rack and pinion system |

| Steering Arm | Arm on the wheel knuckle or spindle | Connects drag link to the wheel assembly | Forged steel | Right-hand steering arm |

Introduction to Drag Link in Automotive Steering

The drag link in automotive steering connects the pitman arm to the steering arm, translating rotational motion from the steering gear into linear movement for wheel control. It plays a crucial role in maintaining precise steering alignment and responsiveness, especially in commercial trucks and off-road vehicles. High-strength steel construction and adjustable ball joints enhance durability and allow for fine-tuning in diverse driving conditions.

Role of Drag Link in Steering Mechanisms

The drag link connects the pitman arm to the steering arm, transmitting steering force from the steering box to the wheels for directional control. It plays a crucial role in maintaining alignment and ensuring smooth, responsive steering by transferring motion precisely. Proper function of the drag link is essential for vehicle stability, handling, and overall safety on the road.

Key Components of a Drag Link Assembly

A drag link assembly in automotive steering systems primarily consists of the drag link itself, tie rod ends, and ball joints, which work together to transfer steering motion from the pitman arm to the steering knuckle. High-strength steel or alloy materials are often used for the drag link to ensure durability and precise control under various driving conditions. Proper lubrication of the ball joints and secure attachment of tie rod ends are critical for maintaining smooth steering response and reducing wear.

Types of Drag Link Configurations

Drag link configurations in automotive steering mechanisms primarily include center-mounted, side-mounted, and offset types. Center-mounted drag links connect the pitman arm directly to the steering arm, offering balanced force distribution and improved steering precision. Side-mounted and offset drag links provide flexibility in alignment and clearance, accommodating various suspension designs and vehicle geometries.

How Drag Link Functions in Recirculating Ball Steering

The drag link in recirculating ball steering connects the pitman arm to the steering arm, transmitting motion from the steering box to the wheels. It converts the rotary motion of the steering gear into linear motion, enabling precise wheel alignment and responsive turning. This component plays a crucial role in maintaining steering accuracy and vehicle stability during operation.

Real-World Example: Drag Link in Heavy-Duty Trucks

The drag link in heavy-duty trucks connects the pitman arm to the steering arm, transmitting steering force while maintaining precise wheel alignment under high loads. Its robust design ensures durability against constant vibrations and torque, essential for handling rough terrains and heavy cargo. Real-world applications reveal drag links made from forged steel alloys to withstand the demanding conditions of commercial trucking operations.

Application of Drag Link in Passenger Cars

The drag link in passenger cars serves as a critical component in the steering mechanism, connecting the pitman arm to the steering arm and facilitating precise wheel alignment and directional control. Commonly found in vehicles with traditional recirculating ball steering systems, the drag link transmits the movement from the steering gearbox to the wheels, ensuring responsive and stable handling. Its design and material must withstand significant mechanical stress and contribute to improved steering accuracy and overall driving safety.

Signs of a Faulty Drag Link

Signs of a faulty drag link in a steering mechanism include uneven tire wear, excessive play or looseness in the steering wheel, and a clunking or knocking noise when turning. A damaged or worn drag link can cause misalignment leading to poor vehicle handling and reduced steering responsiveness. Inspecting the drag link for bent or loose components helps prevent potential steering failures and ensures safe vehicle operation.

Maintenance Tips for Drag Link Longevity

Regular inspection of the drag link, including checking for wear in ball joints and tie rod ends, prevents premature failure in steering systems. Applying high-quality grease to lubrication points reduces friction and protects against corrosion, ensuring smooth operation. Replacing damaged or bent drag links promptly maintains vehicle alignment and safety, extending the lifespan of the steering mechanism.

Drag Link vs. Tie Rod: Key Differences in Automotive Steering

The drag link connects the pitman arm to the steering arm, translating rotary motion from the steering gearbox into linear motion to turn the wheels, while the tie rod links the steering knuckles on either side to synchronize wheel movement. Unlike the drag link, which handles directional input, tie rods primarily maintain wheel alignment and ensure parallel steering. Understanding the distinct functions of the drag link and tie rod is essential for diagnosing steering issues and enhancing vehicle handling performance.

example of drag link in steering mechanism Infographic

samplerz.com

samplerz.com