Scrubbing in the contact patch refers to the small lateral or longitudinal movements between the tire and the road surface as the tire rolls. This phenomenon occurs due to the deformation of the tire tread and the frictional forces acting during cornering, braking, or acceleration. The contact patch is the actual area where the tire meets the road, and scrubbing affects vehicle handling, tire wear, and traction efficiency. During cornering, lateral scrubbing causes the tire to slightly slide relative to the road, generating necessary grip forces for turning. In braking scenarios, longitudinal scrubbing helps the tire maintain traction while slowing down the vehicle. Understanding scrubbing in the contact patch is critical for optimizing tire design, suspension tuning, and overall automotive performance.

Table of Comparison

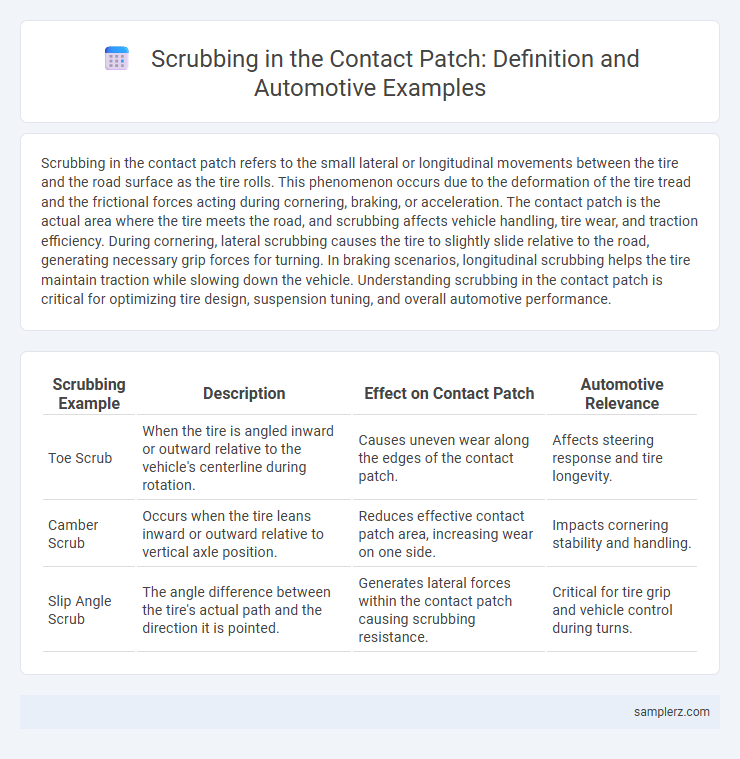

| Scrubbing Example | Description | Effect on Contact Patch | Automotive Relevance |

|---|---|---|---|

| Toe Scrub | When the tire is angled inward or outward relative to the vehicle's centerline during rotation. | Causes uneven wear along the edges of the contact patch. | Affects steering response and tire longevity. |

| Camber Scrub | Occurs when the tire leans inward or outward relative to vertical axle position. | Reduces effective contact patch area, increasing wear on one side. | Impacts cornering stability and handling. |

| Slip Angle Scrub | The angle difference between the tire's actual path and the direction it is pointed. | Generates lateral forces within the contact patch causing scrubbing resistance. | Critical for tire grip and vehicle control during turns. |

Understanding Scrubbing in the Tire Contact Patch

Scrubbing in the tire contact patch occurs when the tire's tread blocks experience lateral sliding relative to the road surface, causing increased friction and wear. This phenomenon is influenced by factors such as tire geometry, load distribution, and steering angle, leading to localized heat generation and rubber degradation. Understanding scrubbing helps optimize tire design and vehicle dynamics to enhance grip, improve fuel efficiency, and prolong tire life.

Common Causes of Scrubbing in Automotive Tires

Scrubbing in automotive tires often results from misalignment issues such as improper toe settings, causing uneven wear on the contact patch. Excessive camber angles and worn suspension components contribute to irregular tire-surface contact, increasing friction and scrubbing. Poor tire inflation and road debris can further exacerbate contact patch scrubbing, reducing tire lifespan and vehicle efficiency.

How Scrubbing Affects Tire Performance

Scrubbing in the contact patch refers to the lateral sliding motion between the tire and the road surface during cornering, causing increased friction and heat buildup. This phenomenon reduces tire grip by wearing down the tread unevenly and generating additional rolling resistance, which negatively impacts fuel efficiency and handling precision. Proper tire alignment and suspension tuning help minimize scrubbing, enhancing overall tire performance and vehicle stability.

Examples of Scrubbing During Cornering Maneuvers

Scrubbing in the contact patch occurs when tires experience lateral slip due to uneven forces during cornering, such as when a front wheel alignment results in excessive toe angle or camber change. For example, during tight cornering at high speed, the inside tire may scrub as it attempts to maintain traction while turning sharply, causing increased tire wear and heat buildup. Another instance is when aggressive trail braking shifts load forward, inducing scrubbing on the front contact patches and affecting vehicle stability.

Scrubbing in Contact Patch During Braking Events

Scrubbing in the contact patch during braking events refers to the lateral or angular movement between the tire and road surface as the brake forces generate frictional resistance. This phenomenon affects tire grip, heat generation, and tread wear, influencing overall vehicle stability and braking performance. Optimizing contact patch behavior through advanced tire compounds and suspension design enhances braking efficiency and safety.

Impact of Wheel Alignment on Scrubbing Patterns

Wheel alignment significantly influences scrubbing patterns within the contact patch by altering the tire's angle relative to the road surface. Misalignment, such as incorrect camber or toe settings, causes uneven scrubbing, increasing tire wear and reducing traction efficiency. Precise alignment ensures uniform contact patch distribution, optimizing vehicle handling and minimizing energy loss due to scrubbing.

Identifying Scrubbing Through Tire Wear Indicators

Scrubbing in the contact patch is identified by uneven tire wear patterns, particularly accelerated wear on the inner or outer edges of the tread, which signals misalignment or improper camber angles. Tire wear indicators, such as tread wear bars, highlight areas where wear exceeds optimal limits, helping diagnose scrubbing-related issues early. Regular inspection of these indicators ensures timely adjustments to suspension or alignment, preserving tire performance and vehicle safety.

Scrubbing Behavior on Different Road Surfaces

Scrubbing behavior in the contact patch varies significantly across different road surfaces, affecting tire wear and vehicle handling. On asphalt, scrubbing results in moderate friction and uniform tread wear, while gravel surfaces increase scrubbing forces, causing accelerated tire degradation and reduced stability. Wet or icy conditions amplify scrubbing inconsistencies, leading to diminished traction and unpredictable vehicle dynamics.

Minimizing Scrubbing for Enhanced Tire Longevity

Minimizing scrubbing in the tire contact patch involves precise suspension alignment and optimal camber angles to reduce lateral tire slip during cornering. Utilizing advanced tread compounds and maintaining correct tire pressure further decreases frictional wear. These measures enhance tire longevity by ensuring even tread wear and reducing heat buildup in the contact area.

Real-World Case Studies of Scrubbing in Vehicle Dynamics

Scrubbing in the contact patch occurs when the tire's rotational axis is offset from the plane of motion, causing increased tire wear and altered steering response, as observed in high-performance racing vehicles navigating tight corners. Real-world case studies demonstrate that precise suspension tuning minimizes scrubbing, enhancing grip and vehicle stability during aggressive maneuvers. Data from motorsport telemetry confirms that reducing scrubbing reduces lateral tire forces, improving overall handling and lap times.

example of scrubbing in contact patch Infographic

samplerz.com

samplerz.com