The squish area in a combustion chamber is the region where the piston comes very close to the cylinder head, causing the air-fuel mixture to rapidly compress and generate turbulence. This turbulence enhances the mixing of fuel and air, leading to improved combustion efficiency and reduced emissions. Common examples of squish areas are found in flat-top pistons with shallow cavities or in pent-roof combustion chambers where the piston crown nearly meets the deck surface. In modern automotive engines, squish areas are carefully designed to optimize combustion chamber shape and increase thermal efficiency. High-performance engines often use squish zones to promote faster flame propagation and improve power output. Measurement of squish clearance and chamber volume is critical for tuning engine performance and meeting emission standards.

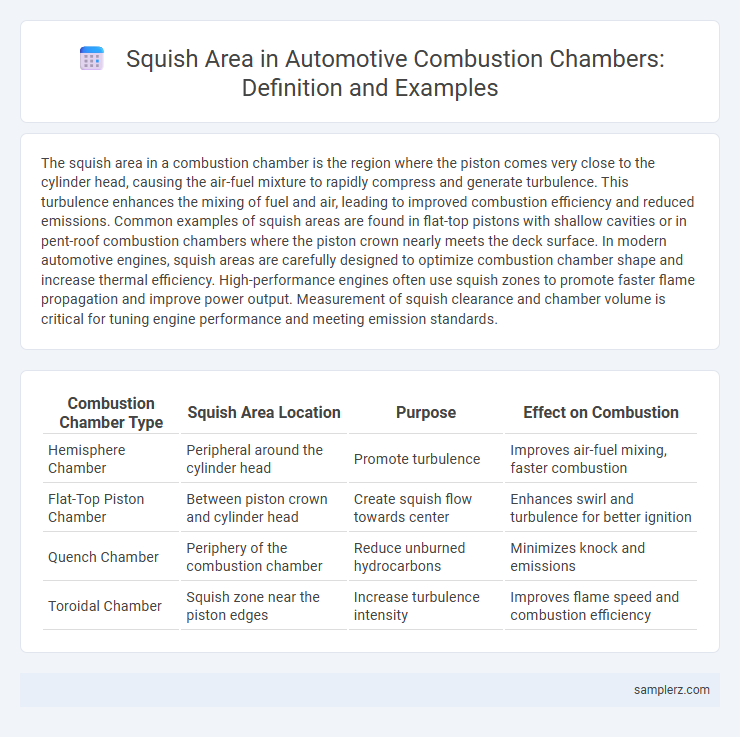

Table of Comparison

| Combustion Chamber Type | Squish Area Location | Purpose | Effect on Combustion |

|---|---|---|---|

| Hemisphere Chamber | Peripheral around the cylinder head | Promote turbulence | Improves air-fuel mixing, faster combustion |

| Flat-Top Piston Chamber | Between piston crown and cylinder head | Create squish flow towards center | Enhances swirl and turbulence for better ignition |

| Quench Chamber | Periphery of the combustion chamber | Reduce unburned hydrocarbons | Minimizes knock and emissions |

| Toroidal Chamber | Squish zone near the piston edges | Increase turbulence intensity | Improves flame speed and combustion efficiency |

Understanding the Squish Area in Combustion Chambers

The squish area in combustion chambers refers to the narrow region between the piston crown and the cylinder head where the air-fuel mixture is rapidly compressed during the compression stroke. This design enhances turbulence, promoting better mixing of the air-fuel mixture and leading to more efficient and complete combustion in automotive engines. Optimizing the squish area improves engine performance and reduces emissions by facilitating quicker flame propagation and reducing knock tendencies.

Importance of Squish Area in Engine Performance

The squish area in a combustion chamber is a critical design feature that enhances air-fuel mixture turbulence, leading to faster and more complete combustion. By reducing crevice volumes and promoting rapid flame propagation, the squish effect improves thermal efficiency and reduces harmful emissions. Optimizing the squish area directly contributes to increased engine power output, better fuel economy, and lower knock tendencies.

Types of Combustion Chamber Designs Featuring Squish Areas

Combustion chamber designs featuring squish areas include hemispherical, pent-roof, and wedge-shaped chambers, each enhancing fuel-air mixture turbulence for improved combustion efficiency. Hemispherical chambers provide a large squish zone that promotes rapid flame propagation and higher thermal efficiency. Pent-roof chambers incorporate angled squish zones to optimize vortex formation, while wedge-shaped chambers utilize a tapered squish area for better flame speed and reduced emissions.

Function and Influence of the Squish Area

The squish area in a combustion chamber functions to rapidly compress the air-fuel mixture by pushing it towards the center of the chamber during the piston's upward stroke, enhancing turbulence for improved mixing and combustion efficiency. This intensified turbulence leads to faster flame propagation, resulting in higher thermal efficiency and reduced emissions in internal combustion engines. Optimizing the squish area shape and clearance directly influences engine performance, power output, and fuel economy by improving volumetric efficiency and minimizing unburned fuel residues.

Example of Squish Area in Hemispherical Combustion Chambers

The squish area in hemispherical combustion chambers is typically positioned around the perimeter of the chamber where the piston crown closely approaches the cylinder head at top dead center. This design creates high-velocity air-fuel mixture motion towards the chamber center, enhancing turbulence for better mixing and faster flame propagation. For example, in performance engines like those used in muscle cars, the hemispherical chamber's squish area significantly improves combustion efficiency and power output.

Example of Squish Area in Wedge-Shaped Chambers

The squish area in wedge-shaped combustion chambers is typically located between the piston crown and the cylinder head, designed to force the air-fuel mixture towards the spark plug for improved combustion efficiency. In a wedge-shaped chamber, the squish band is formed along the narrow edge of the wedge, promoting turbulence and faster flame propagation. This configuration enhances power output and reduces emissions by ensuring more complete fuel burn.

Example of Squish Area in Pentroof Cylinder Heads

The squish area in pentroof cylinder heads is exemplified by the narrow clearance between the piston crown and the flat or slightly curved chamber roof around the periphery of the combustion chamber. This design promotes rapid turbulence and efficient air-fuel mixing, enhancing combustion stability and reducing emissions. Typical squish clearance in pentroof configurations ranges from 0.8 to 1.5 millimeters, optimizing flame propagation and thermal efficiency.

Example of Squish Area in Bathtub-Style Chambers

The squish area in bathtub-style combustion chambers is typically the flat region surrounding the concave piston bowl, designed to enhance air-fuel mixture turbulence at top dead center. This increased turbulence improves combustion efficiency and reduces emissions by promoting better flame propagation. Examples include Honda's earlier VTEC engines, where the squish band effectively increased the turbulence in the combustion chamber for optimized performance.

Optimizing Squish Area for Improved Fuel Efficiency

Optimizing the squish area in a combustion chamber enhances air-fuel mixture turbulence, promoting more complete combustion and reducing fuel consumption. A well-designed squish area minimizes unburned hydrocarbons and lowers emissions by improving flame propagation speed. Precise squish clearance and shape adjustments directly influence fuel efficiency and engine performance in automotive engines.

Common Automotive Engines Utilizing Squish Area Design

Common automotive engines utilizing squish area design include Honda's VTEC series, Toyota's Dynamic Force engines, and Ford's EcoBoost line, all engineered to enhance combustion efficiency by promoting rapid air-fuel mixture turbulence. The squish area, typically found between the piston crown and cylinder head, improves flame propagation and volumetric efficiency, resulting in increased power output and reduced emissions. This design optimization is critical in modern internal combustion engines aiming for better fuel economy while meeting stringent emission standards.

example of squish area in combustion chamber Infographic

samplerz.com

samplerz.com