A pushrod in an automotive engine is a critical component used in overhead valve (OHV) engines to transfer motion from the camshaft to the valves. It is a slender metal rod that moves up and down, actuating the rocker arms which then open and close the intake and exhaust valves. Pushrods enable precise valve timing essential for efficient engine performance and combustion. The use of pushrods is common in V8 engines and many American muscle cars due to their compact design and reliability. Data shows pushrod engines often deliver robust torque at lower RPMs, making them ideal for heavy-duty and performance applications. This mechanism contrasts with overhead camshaft designs, relying on fewer moving parts and providing ease of maintenance and durability.

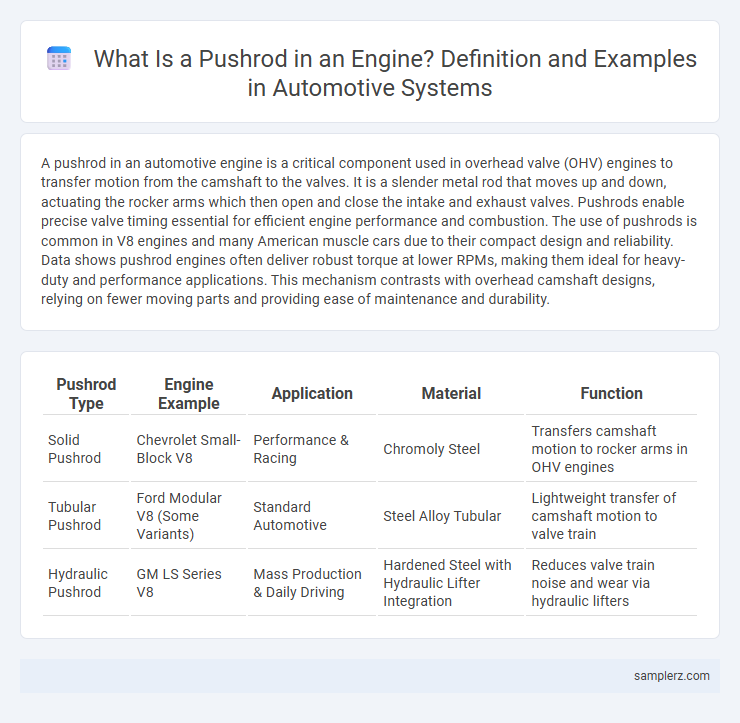

Table of Comparison

| Pushrod Type | Engine Example | Application | Material | Function |

|---|---|---|---|---|

| Solid Pushrod | Chevrolet Small-Block V8 | Performance & Racing | Chromoly Steel | Transfers camshaft motion to rocker arms in OHV engines |

| Tubular Pushrod | Ford Modular V8 (Some Variants) | Standard Automotive | Steel Alloy Tubular | Lightweight transfer of camshaft motion to valve train |

| Hydraulic Pushrod | GM LS Series V8 | Mass Production & Daily Driving | Hardened Steel with Hydraulic Lifter Integration | Reduces valve train noise and wear via hydraulic lifters |

Introduction to Pushrod Engines

Pushrod engines utilize a solid rod to transfer motion from the camshaft located in the engine block to the rocker arms that open and close the valves in the cylinder head. This design simplifies the valvetrain by reducing the number of moving parts above the cylinder head, often resulting in a compact engine architecture preferred in classic American V8 engines like those produced by Chevrolet and Ford. The pushrod system offers advantages in low-end torque and durability, making it favored in trucks and muscle cars despite some limitations in high-revving performance.

What Is a Pushrod in Automotive Engines?

A pushrod in automotive engines is a slender metal rod that transfers motion from the camshaft to the rocker arms, enabling the opening and closing of valves. Commonly used in overhead valve (OHV) engines, pushrods play a critical role in the valve train mechanism by maintaining precise timing and efficient airflow within combustion chambers. Their robust design supports reliable engine performance, particularly in V8 and performance engines where compact valve train architecture is essential.

Historical Overview: Pushrod Technology in Cars

Pushrod technology in automotive engines dates back to the early 20th century, prominently used in flathead and overhead valve (OHV) engine designs. Iconic vehicles like the Chevrolet Small-Block V8, introduced in 1955, exemplify the durability and simplicity of pushrod systems that contributed to widespread adoption in muscle cars and trucks. Despite advancements in overhead camshaft engines, pushrod designs remain favored for their compact size and robust torque characteristics in modern V8 engines.

Key Components of a Pushrod System

A pushrod system in an engine primarily includes the pushrod itself, the rocker arm, and the lifter or cam follower. The pushrod transfers motion from the camshaft to the rocker arm, which then actuates the valve to control airflow in the combustion chamber. These key components are made of durable materials like steel or chromoly to withstand high stress and ensure precise timing in valve operation.

Classic Examples of Pushrod Engines

Classic examples of pushrod engines include the Chevrolet Small-Block V8 and the Chrysler HEMI V8, both renowned for their robust pushrod valvetrain designs that optimize compactness and torque delivery. These engines employ pushrods to transfer motion from the camshaft to the rocker arms, enabling efficient valve actuation within a simpler overhead valve (OHV) configuration. The durability and maintenance simplicity of pushrod engines have made them a staple in American muscle cars and trucks, highlighting their enduring engineering value.

Modern Applications of Pushrods in Vehicles

Pushrods remain a crucial component in modern overhead valve (OHV) engines, especially in muscle cars and trucks, where they contribute to compact engine designs and enhanced durability. Advanced materials like lightweight steel alloys improve pushrod strength and reduce valvetrain weight, optimizing engine performance and fuel efficiency. Manufacturers such as Chevrolet and Dodge continue to use pushrod engines in models like the Corvette and Ram 1500, balancing power delivery with cost-effective production.

Benefits of Pushrod Engine Designs

Pushrod engine designs offer compact engine architecture, enabling smaller engine bays and reducing overall vehicle weight. The simplified valvetrain in pushrod engines enhances reliability and lowers manufacturing costs compared to overhead camshaft systems. This design also provides strong low-end torque, improving vehicle performance in everyday driving conditions.

Limitations of Pushrod Systems in Automotive Engineering

Pushrod systems in automotive engines often face limitations such as restricted valve timing flexibility and higher valvetrain inertia, which can reduce engine efficiency and performance at high RPMs. These constraints hinder the ability to implement advanced variable valve timing and limit the engine's overall power output. Furthermore, pushrod designs typically result in increased mechanical complexity and wear, potentially affecting long-term durability and maintenance.

Maintenance and Durability: Pushrod Engines

Pushrod engines require regular valve lash adjustments to maintain optimal performance and prevent premature wear of the pushrods and valve train components. High-quality pushrod materials, such as hardened steel or chromoly, enhance durability by resisting bending and fatigue under high-stress conditions. Proper lubrication using engine oil with adequate viscosity protects pushrod lifters and rocker arms, ensuring long-term reliability in automotive applications.

Future Trends for Pushrod Engines in the Automotive Industry

Future trends for pushrod engines in the automotive industry emphasize enhanced fuel efficiency and reduced emissions through advanced materials and precision engineering. Integration of electronic valve timing and variable valve lift technology aims to optimize performance while maintaining the compact design advantages of pushrod layouts. Continued development in hybrid powertrains incorporating pushrod engines supports improved torque delivery and durability for light trucks and performance vehicles.

example of pushrod in engine Infographic

samplerz.com

samplerz.com