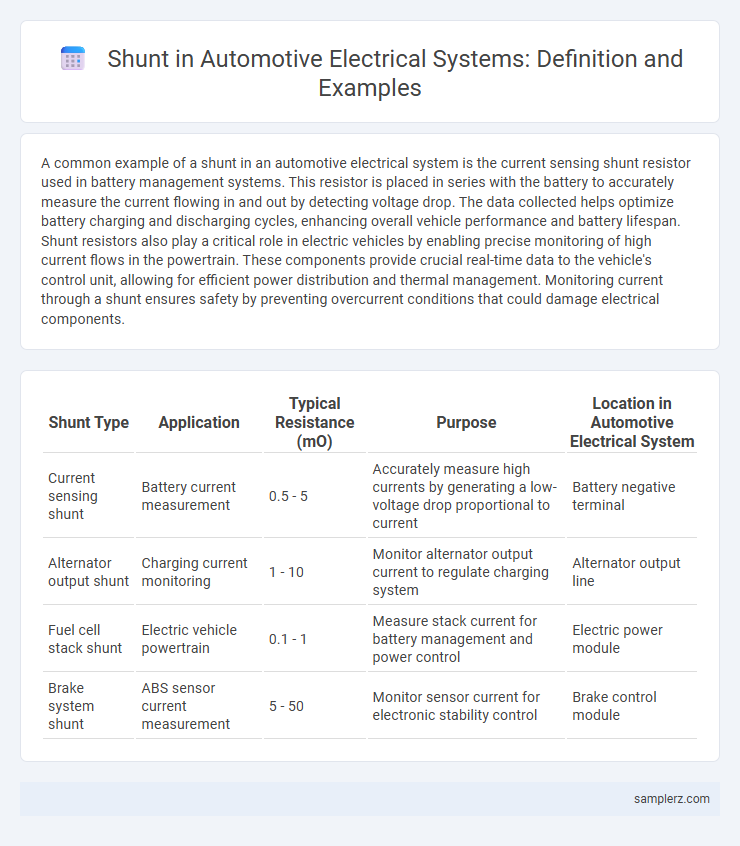

A common example of a shunt in an automotive electrical system is the current sensing shunt resistor used in battery management systems. This resistor is placed in series with the battery to accurately measure the current flowing in and out by detecting voltage drop. The data collected helps optimize battery charging and discharging cycles, enhancing overall vehicle performance and battery lifespan. Shunt resistors also play a critical role in electric vehicles by enabling precise monitoring of high current flows in the powertrain. These components provide crucial real-time data to the vehicle's control unit, allowing for efficient power distribution and thermal management. Monitoring current through a shunt ensures safety by preventing overcurrent conditions that could damage electrical components.

Table of Comparison

| Shunt Type | Application | Typical Resistance (mO) | Purpose | Location in Automotive Electrical System |

|---|---|---|---|---|

| Current sensing shunt | Battery current measurement | 0.5 - 5 | Accurately measure high currents by generating a low-voltage drop proportional to current | Battery negative terminal |

| Alternator output shunt | Charging current monitoring | 1 - 10 | Monitor alternator output current to regulate charging system | Alternator output line |

| Fuel cell stack shunt | Electric vehicle powertrain | 0.1 - 1 | Measure stack current for battery management and power control | Electric power module |

| Brake system shunt | ABS sensor current measurement | 5 - 50 | Monitor sensor current for electronic stability control | Brake control module |

Understanding Shunt Applications in Automotive Electrical Systems

Shunts are essential components in automotive electrical systems used to measure high current by providing a low-resistance path that allows accurate voltage drop measurement. Commonly integrated into battery management systems and current sensing circuits, shunts enable precise monitoring of alternator output and battery discharge rates. Effective shunt applications help optimize electrical performance, ensuring reliable operation of critical vehicle functions like engine control units and electric power steering.

Common Types of Shunt Devices Used in Vehicles

Common types of shunt devices used in automotive electrical systems include resistive shunts, Hall-effect sensors, and Rogowski coils, each designed to measure current flow accurately without interrupting the circuit. Resistive shunts are often embedded in battery management systems for precise current sensing, while Hall-effect sensors detect magnetic fields generated by current, enabling non-intrusive measurements in alternators and starter motors. Rogowski coils, although less common, provide flexible, lightweight solutions for monitoring high transient currents in hybrid and electric vehicle powertrains.

Key Functions of Shunts in Car Electrical Circuits

Shunts in car electrical circuits serve as precise current measurement devices by providing low-resistance pathways that allow accurate amperage readings without interrupting the circuit. They enable the monitoring of battery health and alternator output by converting high current to a proportional voltage drop detectable by the vehicle's control units. This facilitates enhanced management of electrical load distribution and prevents system overloads, ensuring reliable operation of critical automotive components.

Example: Battery Current Shunt for Accurate Charging Monitoring

A battery current shunt in automotive electrical systems is a precision resistor installed in series with the battery's negative terminal to measure current flow accurately. By detecting voltage drop across the shunt, the vehicle's battery management system monitors charging and discharging currents, ensuring optimal battery health and performance. This real-time current measurement enhances charging control, extends battery life, and improves overall automotive electrical system efficiency.

Shunt Placement in Automotive Fuse Boxes

Shunt placement in automotive fuse boxes is critical for accurate current measurement and system protection. Typically positioned parallel to the load circuit, shunts enable precise monitoring of electrical flow without interrupting the main power stream. Proper integration of shunt resistors ensures optimized fault detection and enhances the reliability of vehicle electrical systems.

Role of Shunts in Alternator Output Measurement

Shunts in automotive electrical systems serve as precision resistors that allow accurate measurement of alternator output current by creating a known voltage drop proportional to the current flow. This voltage drop, typically in millivolts, is used by the vehicle's electronic control unit (ECU) or ammeters to monitor charging system performance and ensure optimal battery charging. Accurate current measurement through shunts helps prevent alternator overload and enhances electrical system reliability.

Using Precision Shunts for Electric Vehicle Power Management

Precision shunts play a critical role in electric vehicle power management by providing accurate current measurement within the battery management system (BMS), ensuring safe and efficient energy consumption. These components help monitor high currents flowing between the battery pack and the inverter, enabling real-time data for optimizing charging cycles and preventing overcurrent conditions. High-accuracy shunt resistors contribute to extending battery life and enhancing overall vehicle performance through precise power monitoring and control.

Diagnostic Advantages of Shunt-Based Current Sensing

Shunt-based current sensing in automotive electrical systems offers precise measurement of current flow by detecting voltage drop across a known low-resistance element, enabling accurate diagnostics of battery health and alternator performance. This method enhances fault detection capabilities, such as identifying short circuits or overloads, by providing real-time current data with high resolution. The diagnostic advantages include improved powertrain efficiency monitoring and early detection of electrical anomalies, contributing to vehicle reliability and maintenance optimization.

Shunt Selection Considerations for Automotive Engineers

Selecting a shunt resistor for automotive electrical systems requires careful evaluation of current rating, resistance value, and temperature coefficient to ensure accurate current measurement and system safety. Engineers must consider the automotive environment's thermal stresses and vibration, opting for shunts with robust construction and stable materials to maintain performance under harsh conditions. Precise calibration and compatibility with the vehicle's voltage range are essential to minimize energy loss and support reliable real-time monitoring in battery management and motor control systems.

Safety Precautions When Installing Electrical Shunts in Cars

When installing electrical shunts in automotive systems, ensure the battery is disconnected to prevent electric shock and short circuits. Use insulated tools and wear protective gloves to avoid accidental contact with live wires while securing the shunt to the battery terminal or busbar. Verify all connections are tight and corrosion-free to maintain accurate current measurements and prevent overheating hazards.

example of shunt in electrical system Infographic

samplerz.com

samplerz.com