A ladder chassis is a fundamental structural component used in automotive engineering, particularly in trucks and off-road vehicles. It consists of two long, parallel beams connected by several cross members, forming a shape resembling a ladder. This design provides high strength and durability, supporting heavy loads and withstanding rough terrain conditions. The ladder chassis is often made from steel for its combination of rigidity and cost-effectiveness. It supports key components such as the engine, transmission, and axle assemblies, ensuring stability and safety during vehicle operation. Manufacturers like Toyota and Ford frequently use ladder chassis designs in their pickup trucks and SUVs to achieve enhanced performance and durability.

Table of Comparison

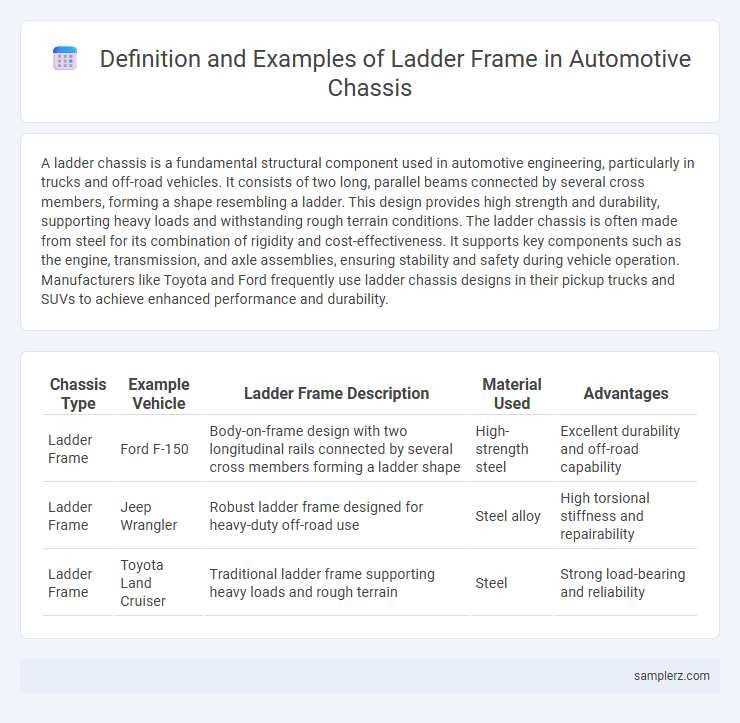

| Chassis Type | Example Vehicle | Ladder Frame Description | Material Used | Advantages |

|---|---|---|---|---|

| Ladder Frame | Ford F-150 | Body-on-frame design with two longitudinal rails connected by several cross members forming a ladder shape | High-strength steel | Excellent durability and off-road capability |

| Ladder Frame | Jeep Wrangler | Robust ladder frame designed for heavy-duty off-road use | Steel alloy | High torsional stiffness and repairability |

| Ladder Frame | Toyota Land Cruiser | Traditional ladder frame supporting heavy loads and rough terrain | Steel | Strong load-bearing and reliability |

Introduction to Ladder Frame Chassis

The ladder frame chassis is a foundational automotive structure characterized by two longitudinal rails connected by several lateral cross members, resembling a ladder. This design offers high strength and durability, making it ideal for trucks, SUVs, and off-road vehicles that require robust support and load-bearing capability. Its simplicity in construction allows for easier modifications and repairs compared to unibody frames.

Key Features of Ladder Chassis Design

The ladder chassis design features two longitudinal beams connected by several cross-members, providing excellent rigidity and strength for heavy-duty automotive applications. It supports high load capacity and easy repairability due to its simple, modular construction, making it ideal for trucks and SUVs. The chassis also enhances vehicle stability and durability, contributing to improved off-road performance and safety.

Historical Evolution of Ladder Frame in Automobiles

The ladder frame chassis, first introduced in early 20th-century automobiles like the Ford Model T, provided a simple yet robust foundation that supported vehicle weight and improved durability. Throughout the mid-1900s, advancements in metallurgy and welding techniques enhanced the ladder frame's strength-to-weight ratio, making it a preferred choice for trucks and off-road vehicles. Modern ladder frames incorporate cross members and boxed sections to further increase torsional rigidity and resistance to twisting forces in heavy-duty automotive applications.

Popular Vehicles Utilizing Ladder Frame Chassis

Popular vehicles utilizing ladder frame chassis include the Toyota Land Cruiser, Ford F-150, and Jeep Wrangler, known for their durability and off-road capability. This chassis design provides excellent strength and rigidity, making it ideal for trucks, SUVs, and heavy-duty vehicles. Ladder frames support higher payloads and better resistance to torsion compared to unibody structures, enhancing performance in rugged environments.

Structural Advantages of Ladder Chassis

The ladder chassis in automotive design provides excellent structural rigidity due to its simple, rectangular frame that evenly distributes load forces. This configuration enhances durability and impact resistance, making it ideal for heavy-duty vehicles and off-road applications. Its straightforward construction also facilitates easier repairs and modifications, optimizing maintenance efficiency.

Comparison: Ladder vs. Monocoque Chassis

A ladder chassis consists of two parallel steel beams connected by several cross-members, providing a strong and rigid foundation ideal for heavy-duty vehicles like trucks and SUVs. In contrast, a monocoque chassis integrates the body and frame into a single unit, delivering superior weight reduction and improved fuel efficiency, commonly used in passenger cars. The ladder chassis excels in durability and off-road performance, while the monocoque design prioritizes structural rigidity and crash safety.

Application of Ladder Chassis in SUVs and Trucks

Ladder chassis are widely applied in SUVs and trucks due to their robust structure and high load-bearing capacity, providing superior durability on rough terrains. This type of chassis supports heavy-duty suspension systems, enhancing off-road performance and stability under substantial weight. Manufacturers often choose ladder frames for vehicles requiring enhanced towing capabilities and increased resistance to torsional stress.

Ladder Chassis in Off-Road and Heavy-Duty Vehicles

Ladder chassis, characterized by two parallel longitudinal beams connected by multiple cross members, provides exceptional strength and durability essential for off-road and heavy-duty vehicles. Its robust design enhances load distribution and resists torsional stresses, making it ideal for rough terrains and heavy payloads. Manufacturers often use high-strength steel to ensure the chassis withstands extreme conditions, contributing to vehicle longevity and performance.

Modern Innovations in Ladder Frame Technology

Modern innovations in ladder frame technology include the use of high-strength steel alloys and aluminum composites that significantly reduce chassis weight while enhancing rigidity. Integration of advanced welding techniques, such as laser welding and robotic automation, improves structural integrity and manufacturing precision. These advancements contribute to improved vehicle handling, crash safety, and fuel efficiency in contemporary automotive chassis design.

Summary: The Future of Ladder Chassis in Automotive Engineering

Ladder chassis, traditionally known for its simplicity and durability, continues to evolve with advanced materials like high-strength steel and aluminum alloys enhancing vehicle performance and fuel efficiency. Modern automotive engineering integrates ladder chassis designs with modular platforms and electric vehicle architectures, optimizing weight distribution and structural integrity. Emerging trends suggest that ladder chassis will play a crucial role in off-road and heavy-duty electric trucks, balancing robustness with sustainability in future automotive innovations.

example of ladder in chassis Infographic

samplerz.com

samplerz.com