Squish in a cylinder refers to the rapid movement of the air-fuel mixture towards the combustion chamber during the compression stroke in an internal combustion engine. This phenomenon occurs as the piston approaches the top dead center, narrowing the space and forcing the mixture to "squish" outwards. Squish improves the air-fuel mixture's turbulence, promoting better combustion efficiency and reducing engine knocking. Manufacturers optimize the squish area in the cylinder head and piston design to enhance engine performance and emissions control. The precise geometry of the squish region influences the swirl and tumble motion of the gases, leading to more complete fuel burning. Engine simulation software often models squish dynamics to predict combustion characteristics and improve engine calibration.

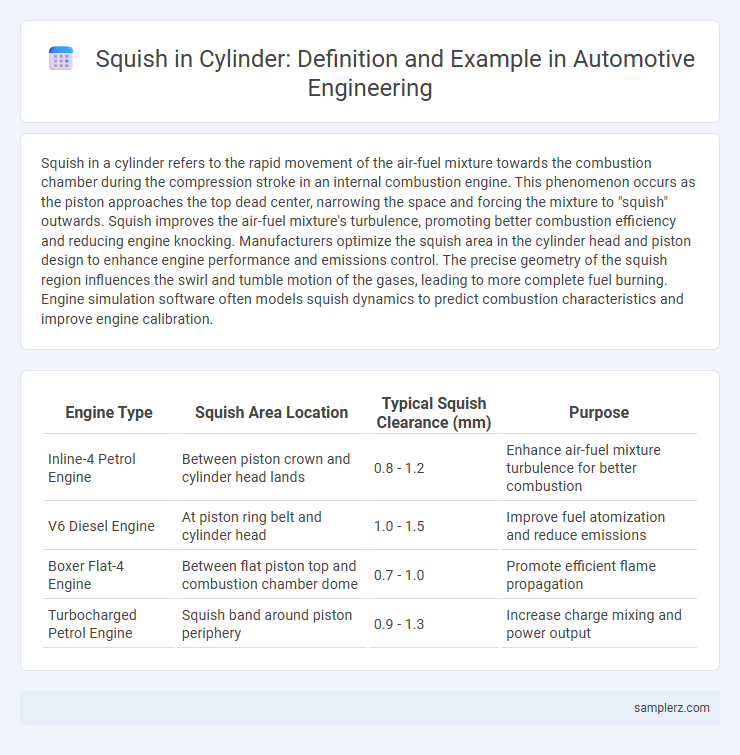

Table of Comparison

| Engine Type | Squish Area Location | Typical Squish Clearance (mm) | Purpose |

|---|---|---|---|

| Inline-4 Petrol Engine | Between piston crown and cylinder head lands | 0.8 - 1.2 | Enhance air-fuel mixture turbulence for better combustion |

| V6 Diesel Engine | At piston ring belt and cylinder head | 1.0 - 1.5 | Improve fuel atomization and reduce emissions |

| Boxer Flat-4 Engine | Between flat piston top and combustion chamber dome | 0.7 - 1.0 | Promote efficient flame propagation |

| Turbocharged Petrol Engine | Squish band around piston periphery | 0.9 - 1.3 | Increase charge mixing and power output |

Understanding Squish in Automotive Cylinders

Squish in automotive cylinders refers to the rapid movement of the air-fuel mixture toward the combustion chamber's central region during the piston's compression stroke, enhancing turbulence and mixing for efficient combustion. Optimizing squish areas within cylinder heads and piston crowns increases flame speed, reduces knock, and improves fuel efficiency. Engine designs utilize precise squish geometry to maximize power output while minimizing emissions and unburned fuel.

How Squish Enhances Combustion Efficiency

Squish in a cylinder refers to the rapid movement of air-fuel mixture towards the combustion chamber's spark plug area during compression, creating turbulence that improves air-fuel mixing. This enhanced turbulence accelerates flame propagation and promotes more complete combustion, leading to increased power output and reduced emissions. Optimizing squish geometry in engines is critical for improving thermal efficiency and fuel economy in modern automotive designs.

Classic Examples of Squish Area Design

Classic examples of squish area design in automotive cylinders include flat-top pistons paired with shallow combustion chambers, which promote efficient air-fuel mixture turbulence and improved combustion efficiency. Hemispherical (hemi) combustion chambers feature raised squish zones that enhance flame propagation speed and reduce knock tendencies. Another notable design is the pent-roof chamber, where multiple squish zones optimize mixture swirl for better power output and emission control.

Role of Squish in Modern Engine Performance

Squish in a cylinder refers to the rapid movement of the air-fuel mixture toward the combustion chamber's center, enhancing turbulence for better atomization and mixing. This improved turbulence increases combustion efficiency and reduces emissions by promoting more complete fuel burn. Modern engines utilize squish design to optimize power output and fuel economy while meeting stringent environmental regulations.

Hemispherical vs. Pentroof: Squish Differences

Hemispherical combustion chambers exhibit moderate squish, concentrating the air-fuel mixture toward the spark plug for efficient ignition, while pentroof designs offer higher squish velocities that enhance turbulence and mixing within the cylinder. The pentroof chamber's angled valve placement and flatter crown create intense squish zones, improving combustion speed and reducing emissions. Hemispherical chambers prioritize flame propagation through symmetrical shape, but pentroof designs optimize volumetric efficiency and thermal performance through superior squish dynamics.

Visualizing Squish Zones in Cylinder Heads

Squish zones in cylinder heads are critical for enhancing combustion efficiency by creating turbulent air-fuel mixtures near the piston crown. Visualizing these zones involves using computational fluid dynamics (CFD) to simulate the airflow and identify areas where the gap between the piston and cylinder head rapidly compresses the mixture. Optimized squish zones improve flame propagation, reduce emissions, and increase engine performance in modern automotive engines.

Impact of Squish on Emission Reduction

Squish in the cylinder creates intense turbulence in the air-fuel mixture, enhancing combustion efficiency and promoting more complete fuel burn. This improved combustion reduces unburned hydrocarbons (HC) and carbon monoxide (CO) emissions by minimizing fuel-rich zones and lowering peak flame temperatures. Optimizing squish geometry directly contributes to cleaner exhaust gases and compliance with stringent emission regulations.

Real-world Applications of Cylinder Squish

Cylinder squish plays a critical role in real-world automotive engines by enhancing air-fuel mixture turbulence, which promotes more efficient combustion and reduces emissions. In high-performance racing engines, optimized squish areas increase flame propagation speed, resulting in improved power output and fuel efficiency. Modern turbocharged engines also utilize cylinder squish to prevent knock by achieving better mixture homogeneity and stable combustion under high pressure.

Optimizing Squish for High-Performance Engines

Optimizing squish in high-performance engine cylinders enhances combustion efficiency by creating rapid turbulence and promoting better air-fuel mixture. Precise squish clearance adjustments, typically between 0.7 to 1.2 mm, increase the velocity of the mixture, resulting in improved flame propagation and higher power output. Engineers utilize computational fluid dynamics (CFD) simulations to refine squish geometry, ensuring maximum pressure and temperature benefits without risking detonation.

Future Trends in Squish Technology

Future trends in squish technology within automotive engines emphasize advanced combustion optimization through variable squish area designs and integrated smart control systems. Emerging materials and manufacturing techniques enable more precise cylinder head geometries, enhancing fuel efficiency and reducing emissions. Innovations in squish dynamics contribute to improved thermal management and support the transition toward cleaner, high-performance internal combustion engines.

example of squish in cylinder Infographic

samplerz.com

samplerz.com