A trunnion in automotive chassis refers to a pivoting support that allows components to rotate or move smoothly under stress. It is commonly found in suspension systems where it connects control arms or stabilizer bars to the vehicle frame. This component is critical for maintaining proper wheel alignment and ensuring stability during vehicle operation. Trunnions are typically made from durable materials such as hardened steel or reinforced alloys to withstand continuous loads and impacts. They often feature bushings or bearings to reduce friction and wear over time. By facilitating controlled movement, trunnions help improve ride comfort, handling precision, and overall chassis durability in automotive design.

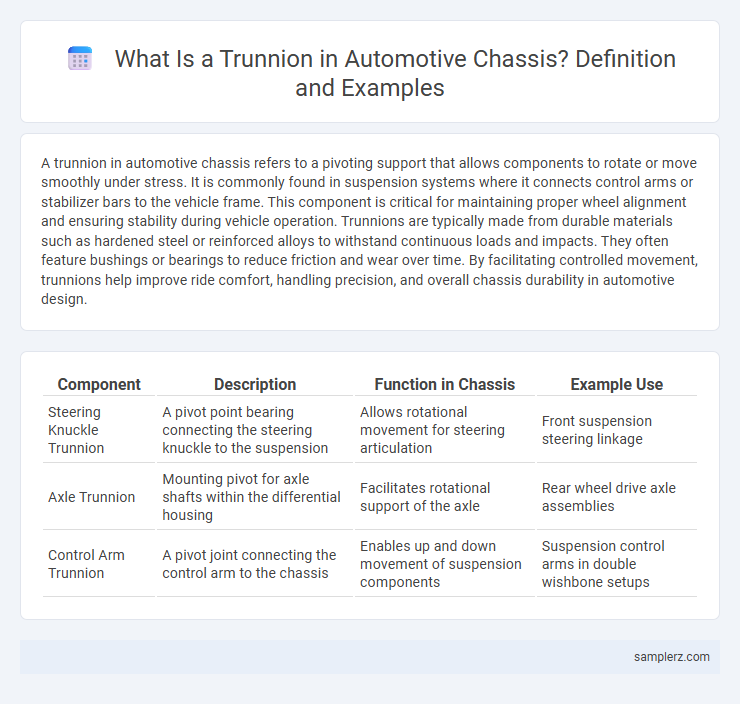

Table of Comparison

| Component | Description | Function in Chassis | Example Use |

|---|---|---|---|

| Steering Knuckle Trunnion | A pivot point bearing connecting the steering knuckle to the suspension | Allows rotational movement for steering articulation | Front suspension steering linkage |

| Axle Trunnion | Mounting pivot for axle shafts within the differential housing | Facilitates rotational support of the axle | Rear wheel drive axle assemblies |

| Control Arm Trunnion | A pivot joint connecting the control arm to the chassis | Enables up and down movement of suspension components | Suspension control arms in double wishbone setups |

Introduction to Trunnions in Automotive Chassis

Trunnions in automotive chassis serve as pivotal components that enable rotational movement between suspension parts, enhancing vehicle stability and handling. These cylindrical bearings or shafts are typically integrated within the control arms or axle assemblies to support load transfer and reduce friction during steering and articulation. Their precise engineering and durable materials ensure long-lasting performance under dynamic driving conditions and varying road impacts.

Definition and Function of Trunnion in Vehicle Chassis

A trunnion in a vehicle chassis is a cylindrical pivot or axle that supports rotational movement and is commonly used in suspension systems to allow controlled articulation. It functions as a critical connection point enabling components like control arms or stabilizer bars to pivot smoothly, enhancing vehicle stability and ride comfort. Trunnions contribute to precise wheel alignment and durability by reducing friction and wear in moving chassis parts.

Historical Development of Trunnion Usage

Trunnion use in automotive chassis dates back to early 20th-century vehicle designs, where they served as pivotal points in suspension systems for improved load distribution and steering control. The evolution of trunnion components paralleled advancements in materials and manufacturing techniques, enabling more durable and precise articulation joints in modern chassis assemblies. Historical adoption of trunnion mounts significantly influenced the development of independent suspension systems, enhancing ride comfort and vehicle handling dynamics.

Key Locations of Trunnions in Chassis Design

Trunnions in chassis design are commonly found at suspension pivot points, enabling controlled rotational motion between the axle and chassis frame. These key locations include front and rear suspension mounts, where trunnions provide durability and precise articulation under varying loads. Proper placement of trunnions enhances vehicle stability and ride comfort by distributing forces efficiently through the chassis structure.

Example: Trunnion Joints in Leaf Spring Suspension

Trunnion joints in leaf spring suspension systems serve as pivotal connection points between the leaf springs and the vehicle chassis, allowing controlled angular movement while supporting heavy loads. These joints typically consist of a cylindrical pin or shaft mounted within a bearing, providing durability and reducing friction under dynamic conditions. This configuration enhances ride stability and maintains suspension alignment in trucks and heavy-duty vehicles.

Trunnion Application in Rear Axle Assemblies

Trunnions in rear axle assemblies serve as pivotal mounting points that facilitate the articulation and alignment of suspension components, enhancing vehicle stability and handling. Their robust design supports the load transmission between the axle housing and suspension arms, ensuring optimal performance under dynamic driving conditions. Precision-engineered trunnion bearings reduce friction and wear, contributing to the durability and longevity of chassis rear-end assemblies in automotive applications.

Benefits of Using Trunnions for Chassis Stability

Trunnions in automotive chassis provide crucial pivot points that enhance suspension flexibility and improve overall vehicle stability during dynamic driving conditions. Their robust design allows for better load distribution, reducing structural stress and increasing the lifespan of chassis components. By enabling controlled articulation, trunnions contribute to superior handling and ride comfort, especially on uneven terrain.

Common Materials Used for Automotive Trunnions

Automotive trunnions in chassis systems are commonly manufactured from high-strength steel alloys and ductile iron due to their excellent load-bearing capacity and resistance to wear and fatigue. Alloy compositions such as chromium-molybdenum steel enhance durability while maintaining lightweight properties essential for vehicle performance. Heat treatment processes like quenching and tempering further improve the mechanical properties, ensuring long service life under dynamic stress conditions.

Modern Alternatives to Traditional Trunnion Design

Modern alternatives to traditional trunnion design in automotive chassis incorporate advanced composite materials and integrated suspension systems to enhance durability and reduce weight. These innovations improve load distribution and vibration damping, resulting in superior vehicle handling and ride comfort. Enhanced manufacturing techniques such as additive manufacturing enable precise customization of trunnion components tailored for electric and autonomous vehicle platforms.

Maintenance and Inspection of Trunnion Assemblies

Regular maintenance and inspection of trunnion assemblies in automotive chassis are critical to ensure safe vehicle operation and prolong component lifespan. Technicians should routinely check for signs of wear, corrosion, and proper lubrication, as neglected trunnions can lead to misalignment or suspension failure. Using advanced diagnostic tools enhances the accuracy of inspections, helping detect early defects in the trunnion pins, bushings, and mounting points.

example of trunnion in chassis Infographic

samplerz.com

samplerz.com