An overcenter spring in a clutch pedal system is a specialized component designed to assist in the smooth operation of the clutch mechanism. This spring is positioned so that when the pedal is pressed or released, it passes through a center point, providing a stable balance between tension and compression. By leveraging this overcenter action, the spring helps reduce pedal effort and improves driver comfort. In automotive applications, overcenter springs are often found in manual transmission vehicles to enhance clutch pedal responsiveness. The spring's design ensures that once the pedal crosses the center position, the force exerted assists in maintaining the pedal's position without requiring continuous pressure from the driver. This mechanism is essential for efficient clutch engagement and helps increase the longevity of the clutch components.

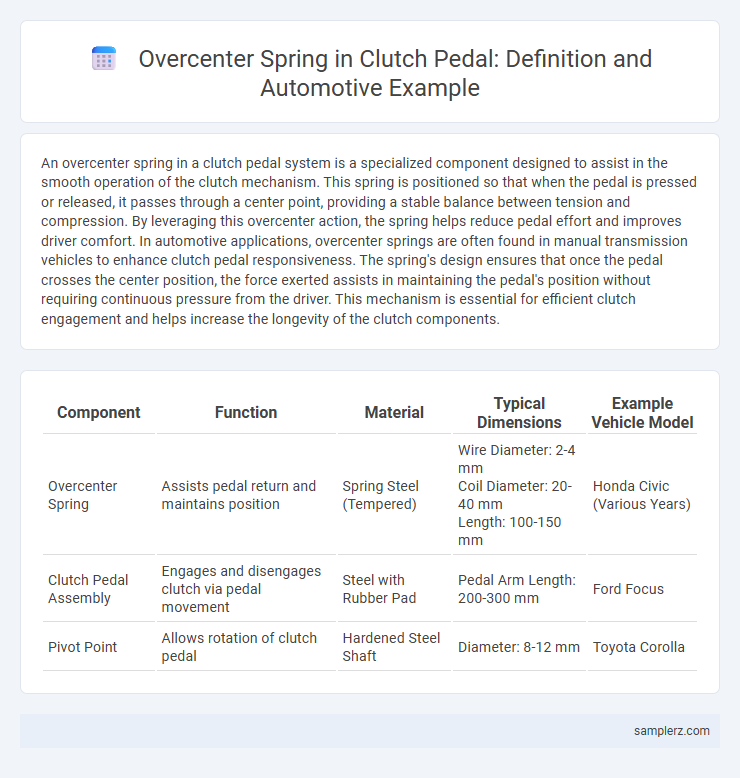

Table of Comparison

| Component | Function | Material | Typical Dimensions | Example Vehicle Model |

|---|---|---|---|---|

| Overcenter Spring | Assists pedal return and maintains position | Spring Steel (Tempered) | Wire Diameter: 2-4 mm Coil Diameter: 20-40 mm Length: 100-150 mm |

Honda Civic (Various Years) |

| Clutch Pedal Assembly | Engages and disengages clutch via pedal movement | Steel with Rubber Pad | Pedal Arm Length: 200-300 mm | Ford Focus |

| Pivot Point | Allows rotation of clutch pedal | Hardened Steel Shaft | Diameter: 8-12 mm | Toyota Corolla |

Understanding Overcenter Springs in Automotive Clutch Pedals

Overcenter springs in automotive clutch pedals provide consistent pedal return force and prevent pedal droop by locking in a stable position when fully pressed or released. These springs enhance driver control and reduce pedal effort by maintaining a balanced tension throughout the clutch engagement cycle. Typical applications include manual transmission systems where precise pedal feedback and reliability are critical for smooth gear shifts.

The Role of Overcenter Springs in Clutch Operation

Overcenter springs in clutch pedals provide precise control by maintaining pedal position and reducing driver effort during engagement and disengagement. These springs store mechanical energy that assists in returning the pedal to its resting state, enhancing clutch system responsiveness and durability. Properly designed overcenter springs contribute to smoother gear shifts and improved overall driving experience.

Key Components of a Clutch Pedal Overcenter Spring Mechanism

The clutch pedal overcenter spring mechanism consists primarily of a torsion spring, a pivot bracket, and a return lever, which work together to maintain pedal stability and assist driver operation. The torsion spring stores energy when the pedal is depressed and releases it as the pedal returns, reducing driver effort and enhancing responsiveness. The pivot bracket acts as the fulcrum, while the return lever ensures smooth engagement and disengagement, preventing pedal rattling and maintaining consistent pressure.

How Overcenter Springs Enhance Clutch Pedal Feel

Overcenter springs in clutch pedals provide a counteracting force that stabilizes pedal movement, reducing driver fatigue during prolonged use. These springs create a distinct tactile feedback, ensuring smooth engagement and disengagement of the clutch while improving overall pedal responsiveness. Enhanced pedal feel contributes to precise clutch control, resulting in better driving performance and safety.

Step-by-Step Example: Overcenter Spring in a Manual Transmission Vehicle

An overcenter spring in a manual transmission clutch pedal provides consistent pedal return and reduces driver fatigue by maintaining tension as the pedal moves past its neutral point. For example, when the driver depresses the clutch pedal, the overcenter spring stretches and then snaps over the pivot point, securing the pedal in position and ensuring smooth disengagement of the clutch. This mechanism improves pedal feel and reliability by preventing slack and maintaining precise clutch control throughout vehicle operation.

Benefits of Using Overcenter Springs in Clutch Pedal Assemblies

Overcenter springs in clutch pedal assemblies provide consistent pedal return force, enhancing driver comfort and reducing fatigue during prolonged use. These springs improve pedal stability by maintaining the clutch in a neutral position, preventing unintended engagement or disengagement. Incorporating overcenter springs also increases the durability of the clutch mechanism by minimizing wear on the pivot and linkage components.

Overcenter Spring Adjustment Procedure for Clutch Pedals

The overcenter spring adjustment procedure for clutch pedals involves ensuring the spring maintains optimal tension to assist pedal return and reduce driver effort. Technicians adjust the spring's position or preload to achieve proper engagement and disengagement, preventing pedal misalignment or excessive free play. Precise calibration enhances clutch responsiveness and prolongs the lifespan of pedal components in automotive applications.

Common Signs of Overcenter Spring Failure in Clutch Pedals

Common signs of overcenter spring failure in clutch pedals include a spongy or inconsistent pedal feel, increased pedal travel, and difficulty disengaging the clutch. Drivers may notice that the pedal does not return smoothly to its resting position or remains stuck in a depressed state. These indicators often lead to clutch engagement issues and can compromise overall vehicle drivability.

Comparing Overcenter Spring Clutch Pedals to Non-Overcenter Designs

Overcenter spring clutch pedals provide a tactile feedback advantage by maintaining consistent pedal return force, improving driver control and reducing fatigue compared to non-overcenter designs. The mechanical advantage in overcenter springs optimizes pedal travel and engagement, enhancing clutch actuation precision in various automotive applications. In contrast, non-overcenter clutch pedals rely on simpler spring mechanisms that may result in less responsiveness and increased wear over time.

Real-World Applications: Popular Cars Using Overcenter Spring Clutch Pedals

Overcenter spring clutch pedals are commonly used in popular vehicles such as the Honda Civic, Ford Mustang, and Toyota Camry to enhance pedal feel and reduce driver fatigue. These springs provide a mechanical advantage by maintaining consistent pressure against the clutch release mechanism, improving control during gear changes. Their integration in mainstream models highlights the engineering focus on durability and ergonomic performance in modern automotive clutch systems.

example of overcenter spring in clutch pedal Infographic

samplerz.com

samplerz.com