The MacPherson strut is a prevalent suspension component in automotive chassis design, commonly found in front suspension systems of many passenger vehicles. It integrates a shock absorber and coil spring into a single unit, optimizing space and improving vehicle handling. This design simplifies the suspension system, reducing weight and manufacturing costs while maintaining effective damping and support. In automotive engineering, the MacPherson strut connects the wheel hub directly to the chassis, allowing for compact packaging and efficient load distribution. It enables precise steering control through its integration with the steering knuckle and provides a crucial role in absorbing road shocks to enhance ride comfort. Data from vehicle dynamics tests often show improved response times and stability, verifying the MacPherson strut's effectiveness in modern chassis systems.

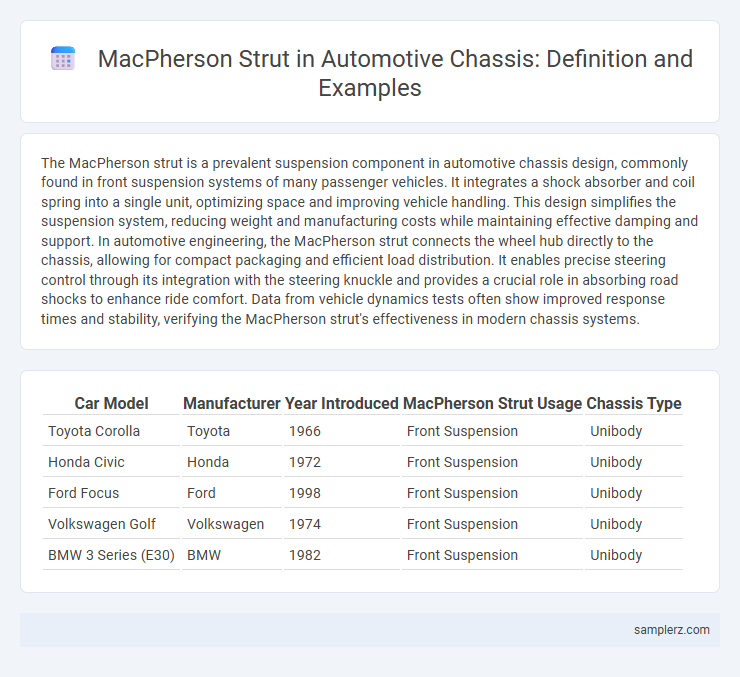

Table of Comparison

| Car Model | Manufacturer | Year Introduced | MacPherson Strut Usage | Chassis Type |

|---|---|---|---|---|

| Toyota Corolla | Toyota | 1966 | Front Suspension | Unibody |

| Honda Civic | Honda | 1972 | Front Suspension | Unibody |

| Ford Focus | Ford | 1998 | Front Suspension | Unibody |

| Volkswagen Golf | Volkswagen | 1974 | Front Suspension | Unibody |

| BMW 3 Series (E30) | BMW | 1982 | Front Suspension | Unibody |

Introduction to MacPherson Strut in Automotive Chassis

The MacPherson strut is a pivotal component in automotive chassis design, combining a shock absorber and coil spring into a single compact unit that supports both suspension and steering functions. Widely used in front-wheel-drive vehicles, it enhances ride comfort while maintaining efficient space utilization and durability. Iconic models such as the Ford Focus and Toyota Corolla exemplify the effective integration of MacPherson strut suspension systems in modern passenger cars.

Historical Development of MacPherson Strut Suspension

The MacPherson strut suspension, developed by Earle S. MacPherson in the 1940s, revolutionized automotive chassis design by combining a shock absorber and coil spring into a single compact unit, which significantly reduced weight and complexity. Its first major application was in the 1950 Ford Vedette, followed by widespread adoption in the 1950s and 1960s across many compact and mid-size vehicles due to its cost-effectiveness and space efficiency. This suspension design fundamentally transformed front-wheel-drive layouts, enhancing vehicle handling and manufacturing efficiency.

Key Components of the MacPherson Strut System

The MacPherson strut system includes a coil spring, a shock absorber, and a strut housing that combines these components into a single unit for suspension support. The upper strut mount connects the strut assembly to the vehicle chassis, allowing pivoting for steering. This design reduces space and weight while providing effective damping and structural rigidity in automotive chassis systems.

Common Vehicles Featuring MacPherson Strut Chassis

Common vehicles featuring MacPherson strut chassis include the Toyota Camry, Honda Civic, and Ford Focus, which utilize this suspension system for its simplicity and cost-effectiveness. The MacPherson strut integrates a shock absorber and coil spring into a single unit, providing efficient front suspension and improved handling in compact and midsize cars. Its widespread adoption in vehicles from manufacturers like Volkswagen and Hyundai highlights its reliability and performance in everyday driving conditions.

Structural Integration of MacPherson Strut in Vehicle Frames

The MacPherson strut's structural integration in vehicle frames enhances chassis rigidity by combining the shock absorber and coil spring into a single, compact unit that directly mounts to the car body and steering knuckle. This design reduces unsprung weight and improves structural efficiency, facilitating better handling and ride comfort. Modern automotive engineers optimize the attachment points and reinforcements around the MacPherson strut to distribute loads evenly and maintain frame integrity under dynamic driving conditions.

Advantages of MacPherson Strut in Modern Chassis Design

MacPherson struts offer a compact and lightweight suspension solution that enhances vehicle handling and stability by reducing unsprung weight. This design simplifies the chassis structure, resulting in cost-effective manufacturing and easier maintenance compared to multi-link systems. Their integration into modern chassis improves ride comfort while maintaining precise wheel alignment and improved road contact.

Limitations of MacPherson Strut Systems

MacPherson strut systems often face limitations in handling high lateral loads, resulting in reduced stability during aggressive cornering. The design restricts suspension travel and camber control, limiting performance in off-road or rough terrain conditions. Additionally, this suspension type can contribute to uneven tire wear and a harsher ride compared to multi-link setups.

Real-World Example: MacPherson Strut in the Toyota Corolla

The Toyota Corolla employs the MacPherson strut suspension system in its front chassis, enhancing ride comfort and handling precision. This design integrates a coil spring and shock absorber into a single unit, reducing weight and improving space efficiency in the vehicle's front assembly. The MacPherson strut in the Corolla contributes to responsive steering and stability, making it a widely adopted choice in compact and midsize passenger cars.

Performance Impact of MacPherson Strut on Ride and Handling

The MacPherson strut significantly enhances ride comfort and vehicle handling by providing a compact, lightweight suspension design that reduces unsprung mass. Its integrated coil spring and shock absorber improve road grip and absorb irregularities, resulting in better stability during cornering and smoother ride quality. This suspension type is commonly utilized in front-wheel-drive vehicles to optimize space efficiency and maintain precise steering control.

Future Trends in MacPherson Strut Suspension Adoption

Emerging innovations in MacPherson strut suspension design leverage lightweight materials and advanced composites to improve vehicle handling and fuel efficiency. Integration of adaptive damping technologies and electronically controlled actuators enables real-time adjustments, enhancing ride comfort and safety in modern automotive chassis systems. Increasing adoption of these smart suspension solutions aligns with industry trends toward electrification and autonomous driving platforms.

example of MacPherson strut in chassis Infographic

samplerz.com

samplerz.com