In automotive engineering, a spider gear is a critical component found in a differential. It consists of small bevel gears mounted on a cross shaft inside the differential carrier. These gears enable the wheels to rotate at different speeds, especially important during cornering to improve traction and vehicle stability. Spider gears interact directly with side gears connected to the vehicle's axle shafts. The differential's spider gear assembly distributes torque evenly between the left and right wheels. This mechanism helps manage the power delivered from the engine, allowing smooth turns without wheel slippage or drivetrain strain.

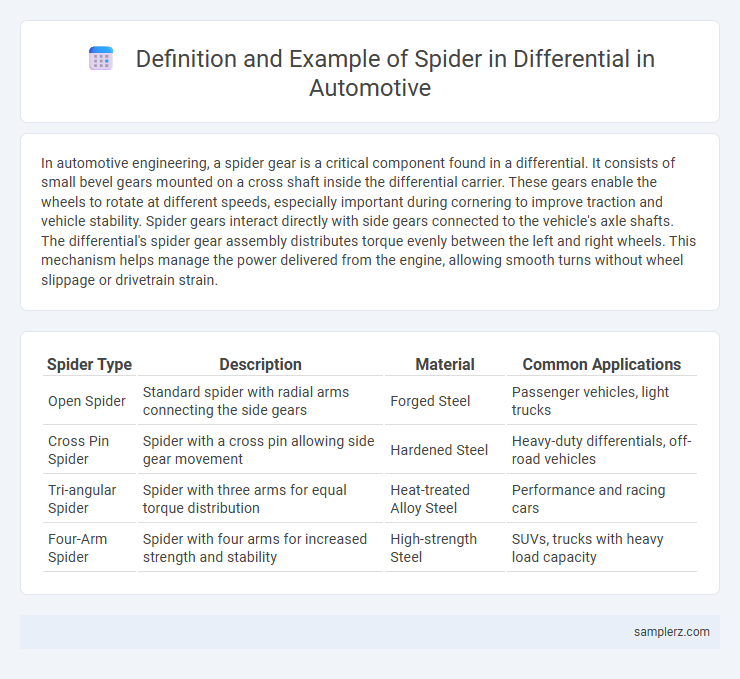

Table of Comparison

| Spider Type | Description | Material | Common Applications |

|---|---|---|---|

| Open Spider | Standard spider with radial arms connecting the side gears | Forged Steel | Passenger vehicles, light trucks |

| Cross Pin Spider | Spider with a cross pin allowing side gear movement | Hardened Steel | Heavy-duty differentials, off-road vehicles |

| Tri-angular Spider | Spider with three arms for equal torque distribution | Heat-treated Alloy Steel | Performance and racing cars |

| Four-Arm Spider | Spider with four arms for increased strength and stability | High-strength Steel | SUVs, trucks with heavy load capacity |

Understanding the Role of the Spider Gear in Differentials

The spider gear in an automotive differential enables the wheels to rotate at different speeds while maintaining power distribution, crucial for smooth cornering. Positioned at the center of the differential carrier, these small bevel gears engage with side gears connected to the axle shafts. Their operation balances torque transfer between wheels, enhancing traction and vehicle handling on diverse road conditions.

Key Components: What Is a Differential Spider?

A differential spider is a critical component within an automotive differential, featuring small, cross-shaped gears known as spider gears. These spider gears allow the wheels to rotate at different speeds while ensuring torque distribution, essential for smooth cornering and improved vehicle handling. Positioned between the side gears, the differential spider facilitates the transfer of power from the driveshaft to the wheels, optimizing traction and stability.

How Spider Gears Enable Smooth Cornering

Spider gears in an automotive differential rotate on a cross shaft, allowing wheels to spin at different speeds when the vehicle turns. These small, bevel gears transfer torque from the drive shaft to the axle shafts, compensating for the difference in distance traveled by the inner and outer wheels. This mechanism reduces tire wear and improves traction, enabling smooth and stable cornering.

Types of Spider Gears Used in Automotive Differentials

Spider gears in automotive differentials typically include two primary types: straight bevel and hypoid gears. Straight bevel spider gears are characterized by their conical shape and straight teeth, offering efficient torque distribution in open differentials. Hypoid spider gears feature an offset pinion, enabling a lower driveshaft position and improved ground clearance, commonly used in modern rear-wheel-drive vehicles for enhanced strength and quieter operation.

Spider Gear Arrangement: Exploded View and Diagram

The spider gear arrangement in a differential features a central cross shaft holding small bevel gears, known as spider gears, which mesh with the side gears attached to the axles. An exploded view or diagram illustrates the precise placement of each spider gear, side gear, and pinion shaft within the differential housing, highlighting their interaction for torque distribution. Understanding this configuration is essential for diagnosing drivetrain issues and performing differential rebuilds in automotive engineering.

Common Materials Used for Differential Spider Gears

Differential spider gears are commonly manufactured from high-strength alloy steels such as 8620 or 9310, which offer excellent durability and wear resistance in automotive applications. These materials are often heat-treated through carburizing processes to enhance toughness and fatigue life while maintaining precise dimensional stability. Using such specialized steel alloys ensures optimal performance and longevity in differential assemblies under varying torque and load conditions.

Real-World Example: Spider Gear Operation in an Open Differential

Spider gears in an open differential allow wheels to rotate at different speeds while distributing engine torque effectively. In a real-world example, when a vehicle turns a corner, the spider gears rotate, enabling the outer wheel to spin faster than the inner wheel, preventing tire slippage and enhancing traction. This mechanism ensures smooth cornering and improved vehicle stability under varying road conditions.

Signs of Spider Gear Wear or Failure in Vehicles

Spider gears in a vehicle's differential often show signs of wear through excessive noise like whining or clunking during acceleration or turns, indicating gear misalignment or damage. Uneven tire wear and vibration while driving can also signal spider gear failure, as these symptoms arise from compromised power distribution to the wheels. Early detection of these signs is crucial to prevent differential lockup or complete drivetrain failure, reducing costly repairs and ensuring vehicle safety.

Upgrading Spider Gears for Performance Applications

Upgrading spider gears in a differential enhances torque distribution and strengthens the gear assembly for high-performance driving conditions. High-quality materials like forged steel and precise machining improve durability and reduce gear slippage in aggressive acceleration and cornering. Installing upgraded spider gears optimizes power transfer efficiency, essential for racing, off-roading, and other demanding automotive applications.

Maintenance Tips for Longevity of Differential Spider Gears

Regularly inspect differential spider gears for wear, corrosion, and proper lubrication to prevent premature failure. Use high-quality gear oil with recommended additives to maintain optimal gear mesh and reduce friction. Ensure timely fluid changes and avoid overloading the vehicle to extend the lifespan of differential spider gears.

example of spider in differential Infographic

samplerz.com

samplerz.com