The dogbone in automotive transmission refers to a small but critical rubber mount that reduces vibrations between the engine and transmission. This component is typically made from durable rubber bonded to metal, acting as a flexible link to absorb engine movement and minimize transmission noise. By isolating engine vibrations, the dogbone mount enhances driving comfort and protects transmission components from excessive wear. In many front-wheel-drive vehicles, the dogbone mount is positioned between the engine block and the transmission housing. Its strategic placement allows it to handle torque fluctuations and maintain optimal alignment of the drivetrain. Data from automotive engineers show that proper maintenance and timely replacement of the dogbone mount significantly improve vehicle stability and prolong transmission lifespan.

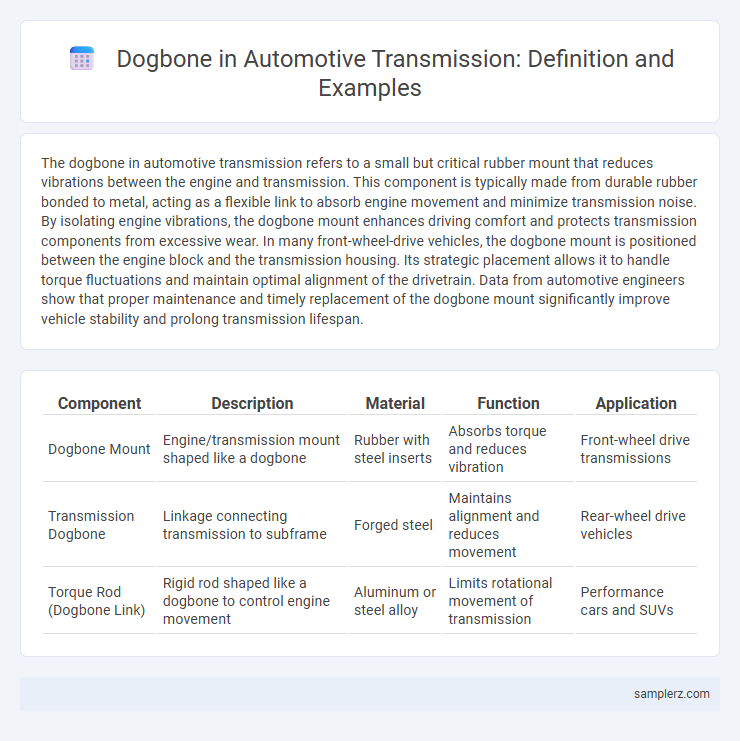

Table of Comparison

| Component | Description | Material | Function | Application |

|---|---|---|---|---|

| Dogbone Mount | Engine/transmission mount shaped like a dogbone | Rubber with steel inserts | Absorbs torque and reduces vibration | Front-wheel drive transmissions |

| Transmission Dogbone | Linkage connecting transmission to subframe | Forged steel | Maintains alignment and reduces movement | Rear-wheel drive vehicles |

| Torque Rod (Dogbone Link) | Rigid rod shaped like a dogbone to control engine movement | Aluminum or steel alloy | Limits rotational movement of transmission | Performance cars and SUVs |

Introduction to Dogbone Components in Automotive Transmissions

Dogbone components in automotive transmissions serve as critical linkage elements that absorb torque fluctuations and reduce vibration between the engine and drivetrain. These elastomeric or metal inserts are designed to enhance durability and smooth power transfer by compensating for minor misalignments. Commonly positioned between the transmission output shaft and driveshaft, dogbones improve overall vehicle performance and reliability.

Role of the Dogbone in Transmission Systems

The dogbone in automotive transmission systems functions as a critical stabilizer that reduces vibrations and misalignment between the engine and gearbox. By absorbing rotational forces and torque fluctuations, it ensures smoother power transfer and protects driveline components from excessive wear. Its ability to accommodate slight angular movements improves overall transmission efficiency and vehicle drivability.

Common Applications of Dogbone Mounts in Vehicles

Dogbone mounts are commonly used in vehicle transmissions to reduce vibrations and enhance drivetrain stability by connecting the engine or transmission to the chassis. These mounts are typically found in rear-wheel-drive and all-wheel-drive vehicles, where they absorb torque-induced movement and minimize noise, vibration, and harshness (NVH). Their application improves overall ride comfort and prolongs the lifespan of transmission components by isolating mechanical stresses.

Materials Used in Dogbone Transmission Mounts

Dogbone transmission mounts commonly utilize high-strength polyurethane and reinforced rubber to absorb vibrations and enhance durability. Steel or aluminum brackets provide structural support, ensuring the mount withstands torsional forces during gear shifts. Advanced composites are increasingly adopted for lightweight performance, improving overall vehicle efficiency and transmission stability.

How Dogbone Links Improve Drivetrain Stability

Dogbone links in automotive transmissions enhance drivetrain stability by minimizing vibrations and reducing torque fluctuations during gear shifts. These elastomeric connectors absorb engine movement and misalignment, ensuring smoother power transfer and improved component longevity. By stabilizing drivetrain dynamics, dogbone links contribute to precise handling and increased vehicle performance.

Symptoms of a Failing Transmission Dogbone

A failing transmission dogbone often causes excessive vibration and clunking noises during gear shifts due to worn or damaged bushings. Drivers may experience difficulty changing gears or a loose, unstable feeling in the drivetrain, indicating compromised torque transfer. Ignoring these symptoms can lead to increased wear on the transmission and drivetrain components, resulting in costly repairs.

Replacing a Dogbone Mount: Step-by-Step Guide

Replacing a dogbone mount in a transmission involves first lifting the vehicle securely and locating the worn mount connecting the transmission to the chassis. After removing the securing bolts with appropriate tools, carefully detach the old dogbone and align the new mount in place, ensuring proper fitment to prevent vibration and drivetrain misalignment. Tighten all fasteners to the manufacturer's torque specifications and test the vehicle for smooth power delivery and reduced engine movement.

Performance Upgrades: Aftermarket Dogbone Options

Aftermarket dogbone mounts in automotive transmissions significantly enhance performance by reducing engine movement and improving power transfer efficiency. High-quality materials such as billet aluminum or polyurethane offer increased durability and stiffness compared to stock rubber mounts. Upgrading to performance dogbones results in improved throttle response, reduced drivetrain slop, and a more connected driving experience.

Impact of Dogbone Wear on Transmission Performance

Dogbone wear in automotive transmissions leads to increased vibration and misalignment, causing inefficient power transfer and accelerated component fatigue. Worn dogbones reduce torque stability, resulting in rough gear shifts and potential transmission failure. Regular inspection and timely replacement of dogbone components directly enhance transmission durability and overall vehicle performance.

Maintenance Tips for Longevity of Transmission Dogbones

Regularly inspect the transmission dogbone for signs of wear or cracking, as early detection prevents costly drivetrain damage. Apply high-quality grease during maintenance intervals to reduce friction and avoid premature joint failure. Ensure bolts are torqued to manufacturer specifications to maintain proper alignment and minimize vibrations affecting transmission performance.

example of dogbone in transmission Infographic

samplerz.com

samplerz.com