In automotive engineering, a ping in an engine refers to abnormal combustion often described as engine knocking or detonation. This phenomenon occurs when the air-fuel mixture ignites prematurely or unevenly within the cylinder, causing a metallic knocking sound. Ping can lead to engine damage by increasing cylinder pressure and temperature beyond designed limits. Sensor data and engine control units (ECUs) play a vital role in detecting and managing ping. Knock sensors detect vibrations caused by abnormal combustion and send signals to the ECU, which adjusts ignition timing and fuel mixture to prevent knocking. Maintaining proper octane fuel, precise timing, and optimized air-fuel ratios helps minimize ping and improve engine efficiency.

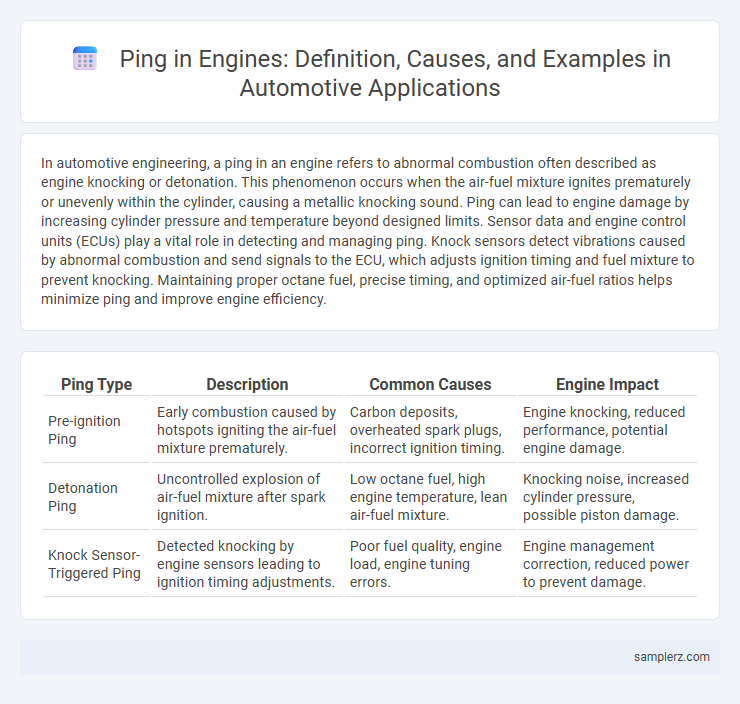

Table of Comparison

| Ping Type | Description | Common Causes | Engine Impact |

|---|---|---|---|

| Pre-ignition Ping | Early combustion caused by hotspots igniting the air-fuel mixture prematurely. | Carbon deposits, overheated spark plugs, incorrect ignition timing. | Engine knocking, reduced performance, potential engine damage. |

| Detonation Ping | Uncontrolled explosion of air-fuel mixture after spark ignition. | Low octane fuel, high engine temperature, lean air-fuel mixture. | Knocking noise, increased cylinder pressure, possible piston damage. |

| Knock Sensor-Triggered Ping | Detected knocking by engine sensors leading to ignition timing adjustments. | Poor fuel quality, engine load, engine tuning errors. | Engine management correction, reduced power to prevent damage. |

Understanding Engine Ping: What Is It?

Engine ping, also known as detonation or knocking, occurs when fuel-air mixture in the combustion chamber ignites prematurely, causing a sharp knocking noise and potential damage. Common triggers include low octane fuel, carbon deposits, or incorrect ignition timing, which disrupt smooth combustion. Detecting and resolving engine ping is crucial to maintaining engine efficiency and preventing expensive repairs.

Common Causes of Engine Ping

Engine ping, often referred to as knocking, is commonly caused by premature combustion of the air-fuel mixture in the combustion chamber. Factors such as low-octane fuel, excessive engine temperature, and incorrect ignition timing frequently contribute to this condition. Carbon deposits on piston crowns and valves can also increase compression, intensifying engine ping and risking engine damage.

Symptoms of Engine Ping in Modern Cars

Engine ping in modern cars often manifests as a metallic knocking noise during acceleration or under heavy load, indicating abnormal combustion. Drivers may notice reduced power output and decreased fuel efficiency as symptoms worsen. Persistent pinging can lead to engine damage, requiring timely diagnosis and corrective measures such as adjusting ignition timing or using higher-octane fuel.

Example Scenarios of Engine Ping

Engine ping, also known as knocking or detonation, occurs when fuel combusts unevenly in the engine cylinders, causing a sharp metallic sound. Common example scenarios include using lower-octane fuel than recommended, excessive engine load during acceleration, and overheating conditions affecting ignition timing. Detecting ping early can prevent potential damage to pistons and improve overall engine performance.

How Poor Fuel Quality Leads to Engine Ping

Poor fuel quality causes incomplete combustion, resulting in abnormal combustion events known as engine ping or knocking. Low-octane fuels have reduced resistance to auto-ignition, leading to early detonation and increased cylinder pressure fluctuations. This rapid combustion damages engine components over time and reduces overall performance and fuel efficiency.

The Role of Ignition Timing in Engine Ping

Engine ping occurs when the air-fuel mixture ignites prematurely due to incorrect ignition timing, causing knocking and reduced efficiency. Precise control of ignition timing ensures the spark plug fires at the optimal moment, preventing abnormal combustion and protecting engine components. Advanced engine management systems continuously adjust timing to minimize ping and maximize performance.

Effects of Engine Overheating on Ping

Engine overheating significantly increases the occurrence of ping or pre-ignition, disrupting the optimal combustion process. Elevated temperatures cause air-fuel mixtures to ignite prematurely, leading to knocking sounds, reduced power output, and potential engine damage. Persistent pinging from overheating can erode piston surfaces, cause cylinder head warping, and decrease overall engine efficiency and longevity.

Real-World Cases of Ping in Different Engines

Real-world cases of engine ping often occur in high-compression performance engines where low-octane fuel triggers detonation, such as in turbocharged vehicles like the Ford EcoBoost or Subaru WRX. Older carbureted engines, including classic muscle cars like the Chevrolet Camaro, frequently experience ping due to improper air-fuel mixtures and ignition timing issues. Diesel engines typically avoid ping but can show similar knocking sounds from fuel injector problems or premature combustion in models like the Ford Power Stroke.

Diagnosing Engine Ping: Practical Steps

Diagnosing engine ping involves listening for a distinctive knocking sound during acceleration and inspecting spark plugs for signs of pre-ignition or detonation. Use a timing light to verify ignition timing and adjust it if advanced beyond the manufacturer's specifications. Checking fuel quality and ensuring proper air-fuel mixture with a diagnostic scan tool helps identify causes of engine knock and optimize combustion performance.

Preventing Engine Ping: Best Maintenance Practices

Engine ping, also known as knocking, occurs when fuel burns unevenly in the combustion chamber, causing metallic knocking noises and potential engine damage. Preventing engine ping involves using high-octane fuel, regularly inspecting spark plugs for wear, and ensuring the ignition timing is correctly adjusted to manufacturer specifications. Maintaining a clean fuel system and timely oil changes also help promote efficient combustion and reduce ping risks.

example of ping in engine Infographic

samplerz.com

samplerz.com