In the automotive industry, a slipper clutch is a specialized component designed to reduce the effects of engine braking and prevent rear wheel lockup during aggressive downshifting. This clutch type allows the clutch to partially slip when the rear wheel tries to drive the engine faster than its speed, enhancing vehicle stability and control. Commonly found in high-performance motorcycles and racing vehicles, slipper clutches improve traction and rider safety by minimizing the chances of the rear wheel skidding. Slipper clutches operate using ramps and cam mechanisms that release pressure on the clutch plates when engine RPM exceeds wheel RPM. This design effectively manages torque transfer during rapid deceleration, allowing smoother transitions between gears. By optimizing torque modulation, slipper clutches contribute to better handling dynamics and extended durability of drivetrain components in automotive applications.

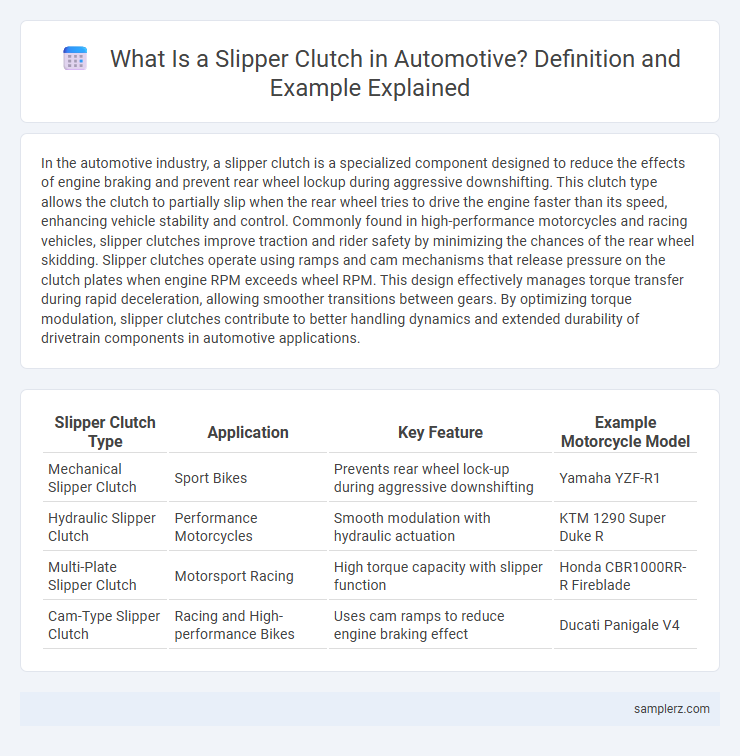

Table of Comparison

| Slipper Clutch Type | Application | Key Feature | Example Motorcycle Model |

|---|---|---|---|

| Mechanical Slipper Clutch | Sport Bikes | Prevents rear wheel lock-up during aggressive downshifting | Yamaha YZF-R1 |

| Hydraulic Slipper Clutch | Performance Motorcycles | Smooth modulation with hydraulic actuation | KTM 1290 Super Duke R |

| Multi-Plate Slipper Clutch | Motorsport Racing | High torque capacity with slipper function | Honda CBR1000RR-R Fireblade |

| Cam-Type Slipper Clutch | Racing and High-performance Bikes | Uses cam ramps to reduce engine braking effect | Ducati Panigale V4 |

Introduction to Slipper Clutch in Automotive Engineering

A slipper clutch in automotive engineering prevents rear wheel lockup during aggressive downshifting by partially disengaging under excessive back torque. This mechanism enhances vehicle stability and reduces drivetrain shock in high-performance motorcycles and racing cars. Designed to improve traction control, slipper clutches are critical components in modern automotive transmission systems.

Key Functions of a Slipper Clutch in Vehicles

A slipper clutch in vehicles primarily reduces the effects of engine braking by allowing partial clutch slippage during aggressive downshifting, preventing rear-wheel lockup. This mechanism enhances rider control and safety, especially in high-performance motorcycles and racing cars. It also helps to minimize drivetrain shock and extend the lifespan of transmission components by absorbing sudden torque spikes.

Top Examples of Slipper Clutch Applications in Motorcycles

Slipper clutches are essential in high-performance motorcycles such as the Kawasaki Ninja ZX-10R, Ducati Panigale V4, and Yamaha YZF-R1, where they prevent rear wheel lockup during aggressive downshifting. These systems enhance rider control by reducing engine braking effects and allowing smoother deceleration through corners. Popular models featuring slipper clutches demonstrate significant improvements in track performance and safety, making them a standard in sportbike engineering.

Automotive Brands Utilizing Slipper Clutch Technology

Honda and KTM are prominent automotive brands utilizing slipper clutch technology to enhance motorcycle performance and safety. Yamaha incorporates slipper clutches in several sportbike models, improving throttle response during aggressive downshifting. Ducati also integrates advanced slipper clutch systems to reduce rear-wheel hop and maintain stability in high-performance motorcycles.

Popular Car Models Featuring Slipper Clutch Systems

Popular car models featuring slipper clutch systems include the Honda Civic Type R, Subaru WRX STI, and Mitsubishi Lancer Evolution, all known for performance-driven engineering. These vehicles leverage slipper clutches to reduce drivetrain shock during aggressive downshifting, enhancing driving stability and control. The integration of slipper clutch technology in these models contributes to improved traction and smoother gear transitions under high-performance conditions.

Comparative Analysis: Standard Clutch vs. Slipper Clutch

A slipper clutch reduces back-torque during aggressive downshifting, preventing rear-wheel hop compared to a standard clutch. Standard clutches offer direct power transfer but are prone to wheel lockup under high engine braking. The slipper clutch's design enhances vehicle stability and control, especially in performance motorcycles and racing applications.

Performance Benefits of Slipper Clutch in Sports Cars

A slipper clutch in sports cars significantly reduces the risk of rear-wheel lockup during aggressive downshifting by allowing controlled slip between the clutch plates. This mechanism enhances vehicle stability and improves cornering performance by preventing sudden engine braking forces. Optimized power delivery and smoother gear transitions contribute to faster lap times and increased driver confidence on the track.

Real-World Scenarios: Slipper Clutch in Action

In high-performance motorcycles, slipper clutches prevent rear-wheel lockup during aggressive downshifting by partially disengaging the clutch, enhancing rider control and safety. Racing bikes utilize slipper clutches to reduce wheel hop and maintain stability under rapid deceleration. This technology improves traction and reduces drivetrain stress, making it essential in competitive motorsports and spirited street riding.

Common Issues Encountered with Slipper Clutches

Slipper clutches in automotive applications often face issues such as uneven wear on clutch plates, leading to reduced performance and increased slipping under high torque. Heat buildup during aggressive driving can cause clutch fade, compromising the smooth engagement and disengagement of the clutch system. Contaminants like oil or dirt infiltrating the clutch assembly also contribute to inconsistent slipper clutch operation and premature component failure.

Future Trends of Slipper Clutch Implementation in Automotive Industry

Future trends in slipper clutch implementation within the automotive industry emphasize enhanced electronic control systems to improve performance and safety in high-powered motorcycles and sport vehicles. Integration of smart sensors allows real-time adjustment of clutch slip to prevent rear-wheel lockup during aggressive downshifting, optimizing traction and stability. Manufacturers are investing in lightweight materials and adaptive software algorithms to support electric and hybrid powertrains, ensuring smoother power delivery and increased longevity of the clutch system.

example of slipper in clutch Infographic

samplerz.com

samplerz.com