In the automotive industry, a jounce occurs when the suspension compresses due to road impacts or heavy loads, causing the damper to absorb significant forces. The damper's role is to control the rebound and compression movements by dissipating kinetic energy as heat, enhancing vehicle stability and ride comfort. During jounce, the damper compresses within its stroke length, preventing metal-to-metal contact and reducing chassis vibrations. A common example of jounce in a damper can be observed in MacPherson strut suspensions found in many passenger vehicles. When the wheel encounters a pothole or speed bump, the damper compresses rapidly to manage the sudden jounce stroke. This action minimizes the upward motion transmitted to the vehicle body, improving tire contact with the road and overall handling performance.

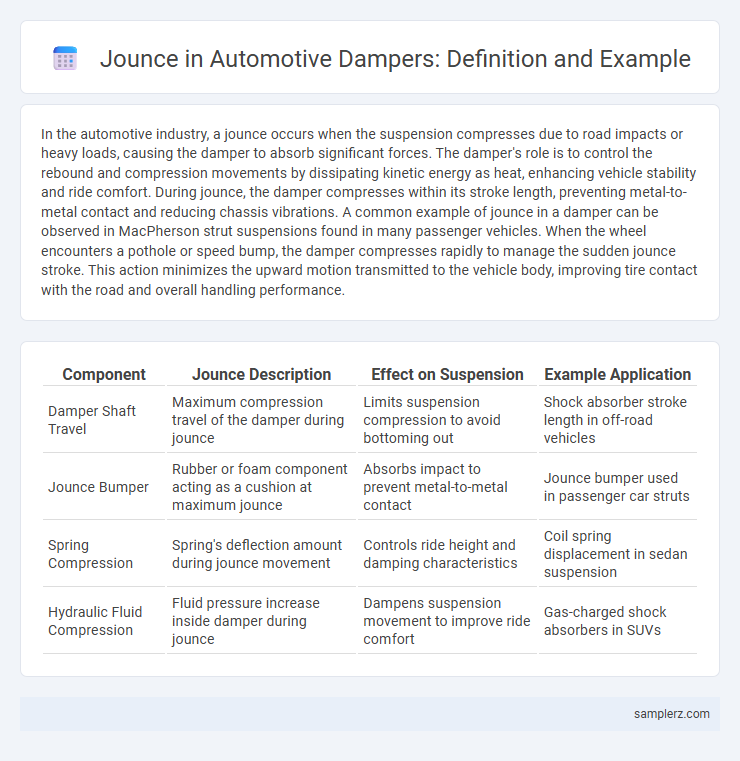

Table of Comparison

| Component | Jounce Description | Effect on Suspension | Example Application |

|---|---|---|---|

| Damper Shaft Travel | Maximum compression travel of the damper during jounce | Limits suspension compression to avoid bottoming out | Shock absorber stroke length in off-road vehicles |

| Jounce Bumper | Rubber or foam component acting as a cushion at maximum jounce | Absorbs impact to prevent metal-to-metal contact | Jounce bumper used in passenger car struts |

| Spring Compression | Spring's deflection amount during jounce movement | Controls ride height and damping characteristics | Coil spring displacement in sedan suspension |

| Hydraulic Fluid Compression | Fluid pressure increase inside damper during jounce | Dampens suspension movement to improve ride comfort | Gas-charged shock absorbers in SUVs |

Understanding Jounce in Automotive Dampers

Jounce in automotive dampers refers to the compression phase when the suspension fully compresses, causing the damper to absorb the maximum shock from road irregularities. Understanding jounce is essential for optimizing ride comfort and vehicle handling by preventing harsh impacts that occur at full suspension travel. High-performance dampers utilize advanced jounce bump stops and tunable valving to control energy dissipation during this critical suspension cycle.

The Role of Jounce in Suspension Systems

Jounce in suspension systems refers to the maximum upward compression of a vehicle's damper during impacts or sudden road irregularities, crucial for absorbing shocks and maintaining tire contact. Effective jounce control enhances ride comfort by minimizing harsh vibrations and protects suspension components from damage by preventing bottoming out. Modern dampers utilize optimized jounce travel and damping rates to improve handling stability and prolong suspension durability under various driving conditions.

Real-World Examples of Jounce Events

During a jounce event, such as when a vehicle abruptly hits a pothole or a speed bump, the damper compresses rapidly to absorb the impact and maintain tire-road contact. High-performance suspensions in SUVs and sport sedans employ monotube or twin-tube dampers specifically designed to handle extreme jounce compression without compromising ride comfort. Testing data from automotive labs shows that dampers can experience up to 100mm of jounce travel during off-road maneuvers, highlighting the critical role of damping force in preventing chassis damage.

How Dampers React During Jounce

During jounce, dampers compress as the vehicle's suspension moves upward, absorbing kinetic energy to reduce impact forces from road irregularities. The damper's piston moves through hydraulic fluid, generating resistance that controls the speed of compression and prevents excessive bouncing. This controlled reaction enhances ride comfort and vehicle stability by minimizing sudden suspension movements.

Jounce vs. Rebound: Key Differences

Jounce in a damper refers to the compression stroke when the suspension moves upward, absorbing impact forces from road irregularities. Rebound describes the extension stroke as the suspension returns to its original position, controlling oscillation and stability. The key difference lies in jounce managing impact absorption and rebound regulating suspension recovery dynamics.

Effects of Jounce on Vehicle Handling

Jounce in a damper refers to the compression limit of the suspension, significantly influencing vehicle handling by affecting ride comfort and stability during sharp impacts. Excessive jounce can lead to bottoming out, reducing tire contact with the road and compromising traction and control in high-speed maneuvers. Optimizing damper jounce characteristics enhances damping force distribution, improving vehicle responsiveness and safety in dynamic driving conditions.

Common Causes of Excessive Jounce

Excessive jounce in automotive dampers commonly results from worn-out shock absorbers, broken coil springs, or damaged bushings that fail to properly absorb road impact. Poorly maintained suspension systems and heavy vehicle loads also contribute to increased jounce travel and reduced ride quality. Detecting excessive jounce early helps prevent further suspension damage and ensures vehicle stability and safety.

Jounce Testing in Automotive Engineering

Jounce testing in automotive engineering evaluates a damper's response to compression forces during suspension load conditions, simulating real-world impacts on vehicle stability and ride comfort. This process measures the damper's ability to absorb shocks when the suspension reaches the maximum compression point, ensuring optimal performance and durability. Accurate jounce testing data helps engineers design dampers that enhance safety, handling, and passenger comfort in various driving environments.

Improving Jounce Performance in Dampers

Improving jounce performance in dampers involves optimizing the design to absorb high-impact forces during severe compression events, such as pothole impacts or off-road conditions. Advanced materials like high-density elastomers and progressive valving technologies enhance energy dissipation and reduce harshness. Integrating multi-stage hydraulic circuits allows for smoother transitions and improved ride comfort while maintaining suspension durability.

Innovations in Damper Design for Better Jounce Control

Innovations in damper design have introduced adaptive jounce bumpers that dynamically adjust stiffness to absorb high-impact forces during suspension compression, improving ride comfort and vehicle stability. Magnetorheological dampers utilize fluid whose viscosity changes in response to magnetic fields, allowing precise jounce control tailored to driving conditions. These advancements reduce harshness and enhance handling by effectively managing jounce events, optimizing overall suspension performance.

example of jounce in damper Infographic

samplerz.com

samplerz.com