A throwout bearing, also known as a clutch release bearing, plays a crucial role in the automotive clutch system. It is responsible for disengaging the clutch when the driver presses the clutch pedal, allowing smooth gear shifting. The bearing slides along the input shaft of the transmission, pressing against the pressure plate's release fingers to separate the clutch disc from the flywheel. In practical automotive applications, the throwout bearing must withstand high rotational speeds and significant friction. Failure or wear of the throwout bearing can lead to noise, difficulty in shifting gears, and complete clutch disengagement failure. Proper maintenance and timely replacement ensure optimal clutch performance and prolong the transmission system's lifespan.

Table of Comparison

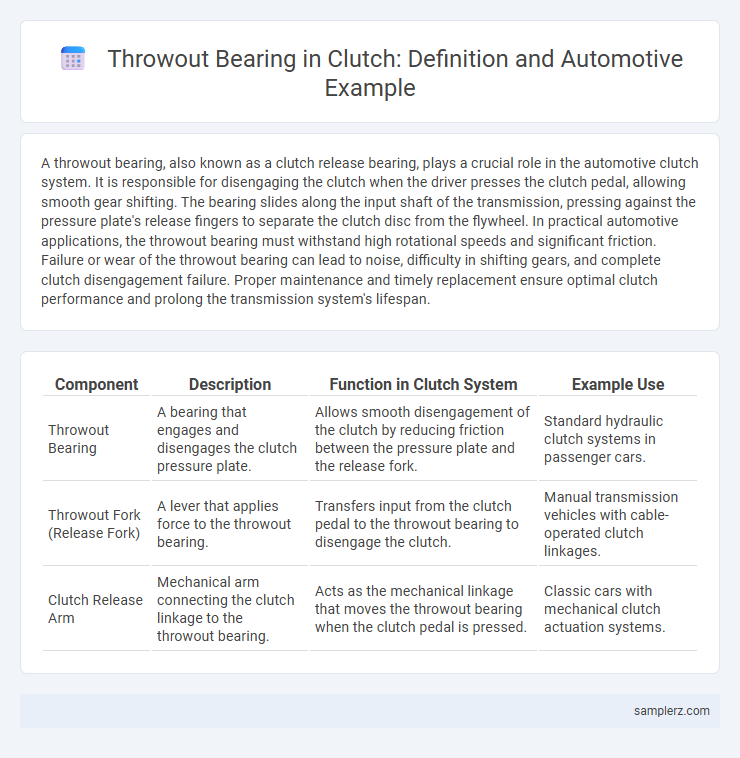

| Component | Description | Function in Clutch System | Example Use |

|---|---|---|---|

| Throwout Bearing | A bearing that engages and disengages the clutch pressure plate. | Allows smooth disengagement of the clutch by reducing friction between the pressure plate and the release fork. | Standard hydraulic clutch systems in passenger cars. |

| Throwout Fork (Release Fork) | A lever that applies force to the throwout bearing. | Transfers input from the clutch pedal to the throwout bearing to disengage the clutch. | Manual transmission vehicles with cable-operated clutch linkages. |

| Clutch Release Arm | Mechanical arm connecting the clutch linkage to the throwout bearing. | Acts as the mechanical linkage that moves the throwout bearing when the clutch pedal is pressed. | Classic cars with mechanical clutch actuation systems. |

Understanding Throwout Bearings in Clutch Systems

Throwout bearings in clutch systems play a critical role by allowing smooth disengagement when the clutch pedal is pressed, preventing friction between the rotating clutch assembly and the stationary linkage. These bearings reduce wear and tear on the clutch fork and enable efficient transfer of force from the pedal to the pressure plate. Proper maintenance and timely replacement of throwout bearings are essential to avoid clutch noise, vibration, or failure in automotive applications.

Common Signs of Throwout Bearing Failure

Common signs of throwout bearing failure in automotive clutches include a high-pitched squealing or chirping noise when the clutch pedal is depressed, grinding sounds during gear shifts, and difficulty in engaging or disengaging the clutch smoothly. Vibration or roughness felt through the clutch pedal often indicates worn or damaged throwout bearings. Early detection of these symptoms can prevent further damage to the clutch assembly and ensure proper vehicle operation.

Role of the Throwout Bearing in Automotive Clutches

The throwout bearing in automotive clutches plays a crucial role by facilitating smooth engagement and disengagement of the clutch system, reducing friction between the rotating clutch assembly and the stationary clutch fork. This component ensures efficient transmission of engine power to the drivetrain by allowing the pressure plate to release the clutch disc when the pedal is pressed. Proper functioning of the throwout bearing prevents premature wear of the clutch and enhances overall vehicle performance.

Examples of Throwout Bearing Malfunctions

Throwout bearing malfunctions in automotive clutches commonly include noise during clutch engagement, rough or stiff clutch pedal operation, and complete failure causing clutch slippage. A worn or damaged throwout bearing may produce a grinding or whining sound when the clutch pedal is depressed, indicating improper bearing rotation. In severe cases, the bearing can seize, preventing disengagement of the clutch, which compromises vehicle drivability and may damage other clutch components.

Symptoms of a Worn Clutch Throwout Bearing

A worn clutch throwout bearing typically causes a distinct grinding or whining noise when the clutch pedal is depressed, indicating metal-on-metal contact. Drivers may experience difficulty shifting gears or a spongy clutch pedal due to improper disengagement of the clutch. Persistent vibration or chatter during clutch engagement also signals potential failure of the throwout bearing in the clutch system.

How Throwout Problems Affect Clutch Performance

Throwout bearing issues can cause increased friction and heat, leading to premature clutch wear or failure. When the throwout bearing is damaged or misaligned, it impedes smooth disengagement of the clutch, resulting in noise, grinding, or difficulty shifting gears. Persistent throwout problems reduce clutch responsiveness and overall vehicle drivability, necessitating timely inspection and maintenance for optimal performance.

Diagnosing Throwout Bearing Issues in Cars

Diagnosing throwout bearing issues in cars involves listening for unusual noises such as squealing or grinding when the clutch pedal is pressed, which indicates wear or damage. Inspecting the bearing for roughness or play during clutch disassembly helps confirm the problem. Timely replacement of a faulty throwout bearing prevents clutch system failure and ensures smooth gear engagement.

Real-world Cases of Throwout Bearing Failure

Throwout bearing failure in automotive clutches often results from prolonged riding of the clutch pedal, causing excessive heat and wear on the bearing surface. Real-world cases frequently show that contaminants like dirt and lack of lubrication accelerate the bearing's degradation, leading to noisy operation and eventual clutch disengagement issues. Timely inspection and replacement are critical to maintaining clutch system reliability and preventing costly transmission damage.

Solutions for Throwout Bearing-Related Clutch Problems

Solutions for throwout bearing-related clutch problems include using high-quality, precision-engineered throwout bearings designed to withstand extreme pressure and heat, ensuring longer service life and smoother clutch operation. Regular maintenance and timely replacement prevent bearing wear and failure, which reduces noise, vibration, and clutch engagement issues. Upgrading to self-adjusting throwout bearing systems can also enhance performance by maintaining optimal bearing clearance and reducing operator effort.

Preventive Maintenance for Throwout Bearings

Regular inspection and lubrication of throwout bearings in automotive clutch systems significantly prolong their lifespan and prevent premature failure. Monitoring bearing noise and ensuring proper adjustment reduces the risk of clutch slippage and costly repairs. Implementing a scheduled preventive maintenance routine enhances vehicle performance and reliability by maintaining optimal throwout bearing function.

example of throwout in clutch Infographic

samplerz.com

samplerz.com