A stator in an alternator is a stationary component that contains coils of wire, often made of copper, arranged in a circular pattern. Its primary role is to generate a rotating magnetic field when electrical current flows through these coils. The stator works in conjunction with the rotor, which rotates inside it, to convert mechanical energy from the engine into electrical energy. In automotive applications, the alternator stator typically consists of three-phase windings that produce alternating current (AC) as the rotor spins. This AC current is then converted to direct current (DC) by the rectifier to charge the vehicle's battery and power electrical systems. Stators are designed to withstand significant heat and vibrations typical in engine compartments, ensuring reliable performance and longevity.

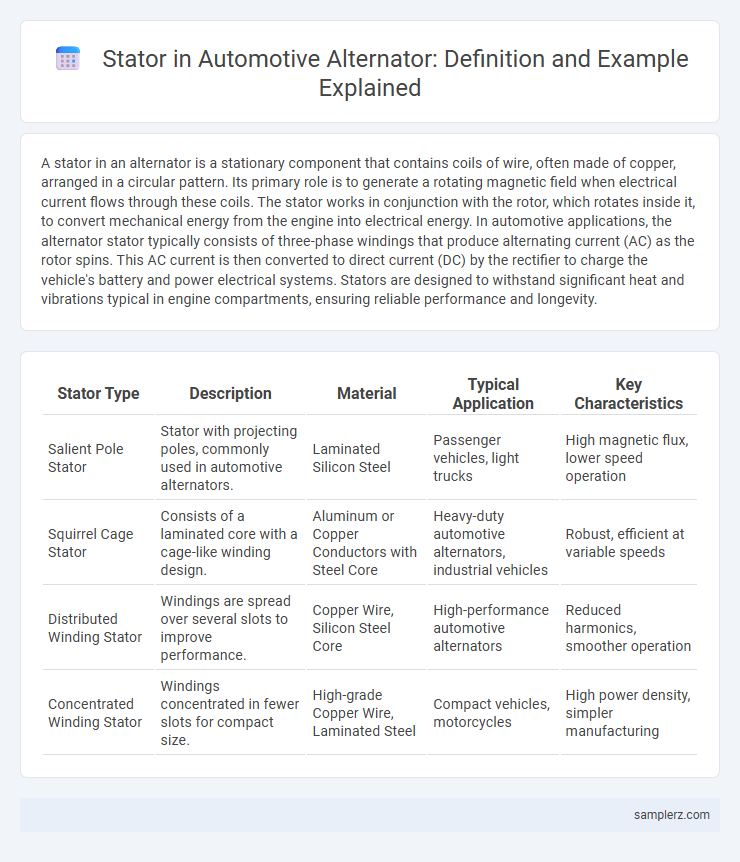

Table of Comparison

| Stator Type | Description | Material | Typical Application | Key Characteristics |

|---|---|---|---|---|

| Salient Pole Stator | Stator with projecting poles, commonly used in automotive alternators. | Laminated Silicon Steel | Passenger vehicles, light trucks | High magnetic flux, lower speed operation |

| Squirrel Cage Stator | Consists of a laminated core with a cage-like winding design. | Aluminum or Copper Conductors with Steel Core | Heavy-duty automotive alternators, industrial vehicles | Robust, efficient at variable speeds |

| Distributed Winding Stator | Windings are spread over several slots to improve performance. | Copper Wire, Silicon Steel Core | High-performance automotive alternators | Reduced harmonics, smoother operation |

| Concentrated Winding Stator | Windings concentrated in fewer slots for compact size. | High-grade Copper Wire, Laminated Steel | Compact vehicles, motorcycles | High power density, simpler manufacturing |

Introduction to Stator in Automotive Alternators

The stator in automotive alternators consists of a stationary set of wire windings that generate alternating current when the rotor spins inside it. This component plays a crucial role in converting mechanical energy from the engine into electrical energy to power the vehicle's electrical systems and charge the battery. High-quality stator designs enhance efficiency and durability, directly impacting the alternator's performance and longevity.

Key Functions of the Alternator Stator

The alternator stator plays a crucial role in converting mechanical energy into electrical energy by housing the stationary windings through which the rotating magnetic field induces alternating current. Its key functions include generating a consistent AC voltage, ensuring efficient magnetic flux interaction, and maintaining structural integrity to handle electromagnetic forces. This component directly impacts the overall performance and reliability of the vehicle's electrical charging system.

Construction and Design of Alternator Stators

The alternator stator consists of a laminated iron core with slots to accommodate copper wire windings, designed to maximize electromagnetic induction efficiency. High-grade silicon steel laminations reduce eddy current losses, enhancing the stator's durability and performance. Precise winding patterns and insulation materials ensure optimal electrical conductivity and thermal resistance within the stator assembly.

Common Materials Used in Stator Windings

Stator windings in automotive alternators are primarily made from copper due to its excellent electrical conductivity and thermal resistance, ensuring efficient energy conversion and durability under high-temperature conditions. Aluminum is occasionally used as a cost-effective alternative, but it offers lower conductivity and may impact overall performance. Insulating materials like enamel coatings on copper wire and phenolic resin are critical for preventing electrical shorts and enhancing the longevity of the stator assembly.

Working Principle: How the Stator Generates Electricity

The stator in an automotive alternator generates electricity through electromagnetic induction, where its stationary coil windings are exposed to a rotating magnetic field produced by the rotor. As the rotor spins, the magnetic flux changes within the stator windings, inducing an alternating current (AC). This AC is then converted to direct current (DC) by the rectifier to charge the vehicle's battery and power electrical systems.

Stator Types Used in Automotive Alternators

Automotive alternators commonly use stators with either claw-pole or laminated core designs to efficiently generate electrical power. Claw-pole stators feature an iron core with multiple coils wound around teeth, optimizing magnetic flux and improving durability in engine environments. Laminated core stators minimize eddy current losses through stacked steel plates, enhancing alternator efficiency and thermal management in modern vehicles.

Example of Stator Configuration in Modern Vehicles

Modern vehicle alternators typically feature a stator with a three-phase winding configuration, enhancing electrical output efficiency and reliability. This stator design consists of laminated iron cores with evenly spaced slots wound with copper wire, optimizing magnetic flux generation during engine operation. Advanced materials and precise coil arrangements improve durability and power delivery, supporting the high electrical demand of contemporary automotive systems.

Symptoms of a Faulty Alternator Stator

A faulty alternator stator can cause dim or flickering headlights, inconsistent dashboard warning lights, and difficulty starting the vehicle. Engine stalling and irregular electrical system performance often indicate stator coil damage or short circuits. Early detection of stator faults prevents battery drainage and ensures reliable power generation for the vehicle's electrical components.

Maintenance Tips for Alternator Stators

Regular inspection of the alternator stator for signs of wear, corrosion, or burnt windings ensures optimal electrical performance and prevents unexpected failures. Cleaning the stator using appropriate solvents removes dirt and debris that can cause overheating and shorts. Ensuring tight and secure connections within the stator coil reduces resistance and improves charging efficiency in automotive electrical systems.

Advancements in Stator Technology for Automotives

Advancements in stator technology for automotive alternators include the development of high-efficiency magnetic materials like silicon steel alloys and the integration of innovative winding techniques such as hairpin coils, which enhance conductivity and reduce energy losses. Precision manufacturing methods such as laser welding and automated winding enable tighter tolerances and improved thermal management, resulting in increased durability and performance under high-load conditions. These innovations contribute to more compact, lightweight alternators that support the growing electrical demands of modern vehicles, including advanced driver-assistance systems (ADAS) and electric powertrains.

example of stator in alternator Infographic

samplerz.com

samplerz.com