Flutter in a turbocharger refers to the rapid oscillation of the compressor wheel or turbine blades, often caused by unstable airflow or pressure fluctuations. This phenomenon occurs when the pressure downstream of the compressor drops below the compressor's outlet pressure, leading to airflow reversal and vibration. Data from automotive tests indicate that turbo flutter typically manifests at high boost pressures or during sudden throttle lift-off events. Engine calibration engineers monitor boost pressure sensors and mass airflow data to detect flutter events and prevent damage to the turbocharger components. Modern turbochargers incorporate anti-flutter valves or blow-off valves designed to release excess pressure and stabilize airflow. These components help maintain consistent boost pressure, protecting the turbocharger from mechanical stress and enhancing engine performance reliability.

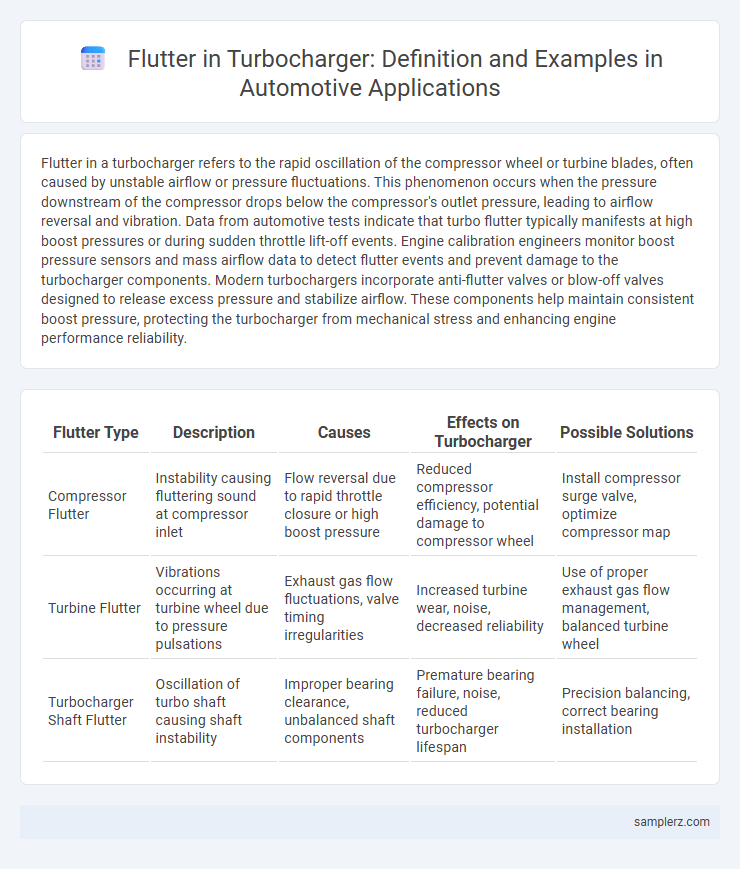

Table of Comparison

| Flutter Type | Description | Causes | Effects on Turbocharger | Possible Solutions |

|---|---|---|---|---|

| Compressor Flutter | Instability causing fluttering sound at compressor inlet | Flow reversal due to rapid throttle closure or high boost pressure | Reduced compressor efficiency, potential damage to compressor wheel | Install compressor surge valve, optimize compressor map |

| Turbine Flutter | Vibrations occurring at turbine wheel due to pressure pulsations | Exhaust gas flow fluctuations, valve timing irregularities | Increased turbine wear, noise, decreased reliability | Use of proper exhaust gas flow management, balanced turbine wheel |

| Turbocharger Shaft Flutter | Oscillation of turbo shaft causing shaft instability | Improper bearing clearance, unbalanced shaft components | Premature bearing failure, noise, reduced turbocharger lifespan | Precision balancing, correct bearing installation |

Understanding Flutter Phenomenon in Turbochargers

Flutter in turbochargers refers to the rapid oscillation of the compressor wheel caused by pressure fluctuations in the intake system, often leading to compressor surge. This phenomenon typically occurs when the throttle closes suddenly, causing a reversed airflow that forces the compressor wheel to stall and vibrate. Understanding flutter is crucial for optimizing turbocharger design and improving efficiency, durability, and overall engine performance.

Causes of Flutter in Automotive Turbocharger Systems

Flutter in automotive turbocharger systems primarily arises from compressor surge, which occurs when the throttle closes suddenly, causing reverse airflow through the compressor wheel. This flow instability generates pressure oscillations and damaging vibrations concentrated at specific frequencies related to the turbocharger's rotational speed and compressor map characteristics. Inadequate wastegate control and insufficient boost pressure management further exacerbate flutter, leading to reduced turbocharger efficiency and potential mechanical failure.

Symptoms and Signs of Turbocharger Flutter

Turbocharger flutter manifests as a distinctive chattering or rattling noise during acceleration, often caused by the rapid oscillation of the compressor wheel due to improper bypass valve function or boost pressure irregularities. Drivers may experience reduced engine performance, inconsistent boost delivery, and potential surge events that can lead to mechanical stress on the turbocharger components. Recognizing these symptoms early allows for inspection of the wastegate, blow-off valve, and compressor housing to prevent further damage.

Real-World Examples of Turbo Flutter in Vehicles

Turbo flutter, a distinct sound caused by compressed air rapidly reversing through the turbo system, is commonly observed in vehicles featuring performance turbochargers, such as the Subaru WRX STI and Ford Fiesta ST. This phenomenon occurs during gear changes or sudden throttle lifts, where the wastegate or blow-off valve momentarily traps excess boost pressure, producing the characteristic flutter noise. Enthusiasts often seek this effect for its aggressive auditory feedback, highlighting the interplay between turbocharger design and real-world driving dynamics.

Effects of Flutter on Turbocharger Performance

Flutter in turbochargers causes pressure fluctuations that reduce compressor efficiency and induce noise and vibration, leading to potential mechanical damage. These oscillations disrupt airflow stability, resulting in decreased boost pressure and delayed turbo response. Mitigating flutter through optimized turbine design improves overall engine performance and longevity.

Diagnosing Turbocharger Flutter in Modern Engines

Diagnosing turbocharger flutter in modern engines involves detecting abnormal vibrations and pressure fluctuations caused by compressor surge or rapid throttle changes. Using advanced sensors and engine control unit (ECU) diagnostics, technicians can monitor turbocharger speed, boost pressure, and airflow to identify flutter conditions. Early detection prevents compressor damage and ensures optimal turbocharger performance in high-efficiency gasoline and diesel engines.

Preventing Flutter: Best Practices for Turbo Maintenance

Preventing flutter in turbochargers involves regular inspection of the wastegate and blow-off valve to ensure proper operation and avoid pressure irregularities that cause compressor surge. Maintaining clean air filters and ensuring tight, leak-free intake piping reduces the risk of fluctuations that lead to flutter. Using high-quality lubricants and monitoring turbo shaft play during maintenance checks also helps preserve turbocharger health and prevent flutter-induced damage.

Impact of Turbo Flutter on Vehicle Reliability

Turbo flutter, a characteristic spooling noise caused by pressure waves in the turbocharger compressor, can indicate irregular airflow and result in compressor surge. This phenomenon increases stress on turbocharger components, accelerating wear and reducing the lifespan of critical parts like the turbine wheel and shaft. Persistent turbo flutter can ultimately compromise vehicle reliability by leading to premature turbocharger failure and degraded engine performance.

Innovations to Mitigate Turbocharger Flutter

Turbocharger flutter, characterized by rapid pressure oscillations, can cause significant noise and component wear in automotive engines. Innovations such as variable geometry turbochargers (VGT) and active wastegate controls optimize airflow, effectively reducing flutter by maintaining steady boost pressure. Advanced materials in turbine blades and enhanced compressor maps also contribute to improved durability and smoother performance, minimizing the impact of turbocharger flutter.

Future Trends in Addressing Flutter in Automotive Turbochargers

Emerging materials such as advanced ceramics and carbon composites improve flutter resistance in automotive turbochargers by enhancing structural integrity and reducing mass. Integration of real-time sensor networks paired with AI-driven control algorithms enables precise monitoring and adaptive adjustments to minimize flutter-induced vibrations. Future trends emphasize additive manufacturing to create optimized geometries that further suppress flutter and extend turbocharger lifespan.

example of flutter in turbocharger Infographic

samplerz.com

samplerz.com