Just-in-time (JIT) in business is a supply chain strategy where companies receive goods only as they are needed in the production process, minimizing inventory costs. Toyota is a prime example of JIT implementation, using this method to improve efficiency and reduce waste in automobile manufacturing. This approach allows Toyota to respond quickly to changes in customer demand while maintaining lower storage expenses. Many electronics manufacturers also use JIT to streamline operations and reduce excess inventory. Dell, for instance, assembles computers only after receiving customer orders, which limits overproduction and lowers holding costs. By aligning production schedules closely with sales orders, Dell enhances cash flow and maintains a lean inventory system.

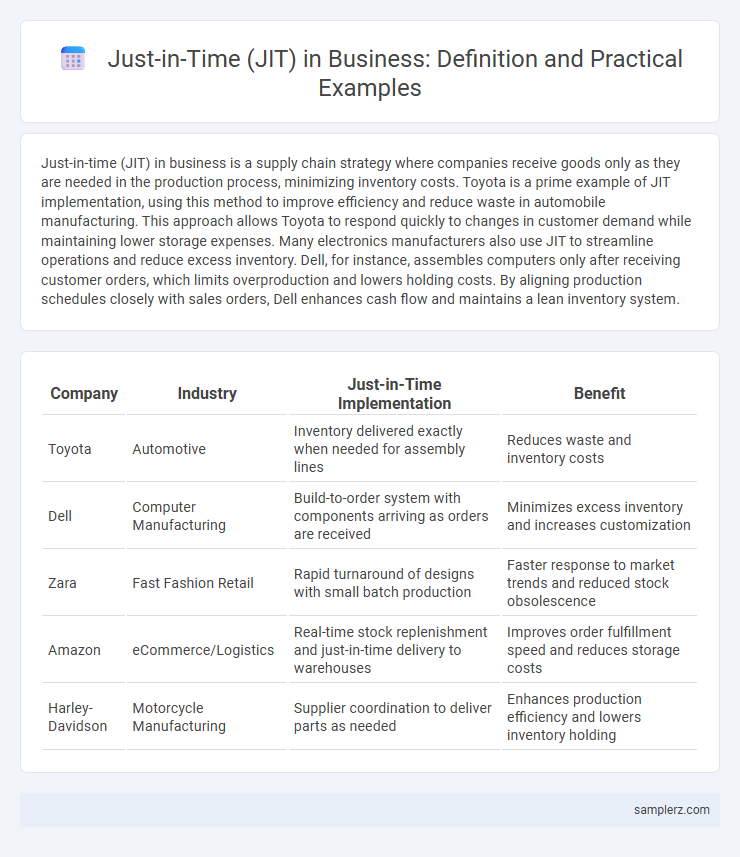

Table of Comparison

| Company | Industry | Just-in-Time Implementation | Benefit |

|---|---|---|---|

| Toyota | Automotive | Inventory delivered exactly when needed for assembly lines | Reduces waste and inventory costs |

| Dell | Computer Manufacturing | Build-to-order system with components arriving as orders are received | Minimizes excess inventory and increases customization |

| Zara | Fast Fashion Retail | Rapid turnaround of designs with small batch production | Faster response to market trends and reduced stock obsolescence |

| Amazon | eCommerce/Logistics | Real-time stock replenishment and just-in-time delivery to warehouses | Improves order fulfillment speed and reduces storage costs |

| Harley-Davidson | Motorcycle Manufacturing | Supplier coordination to deliver parts as needed | Enhances production efficiency and lowers inventory holding |

Introduction to Just-in-Time (JIT) in Business

Just-in-Time (JIT) in business is an inventory management strategy aimed at reducing waste by receiving goods only as they are needed in the production process, improving efficiency and decreasing inventory costs. Toyota is a prime example of JIT implementation, drastically minimizing inventory levels while maintaining high product quality and streamlining operations. This approach aligns production schedules closely with demand forecasts, enabling companies to respond quickly to market changes and reduce overhead expenses.

Key Principles of Just-in-Time Methodology

The Just-in-Time (JIT) methodology emphasizes minimizing inventory levels by receiving goods only as they are needed in the production process, reducing waste and storage costs. Key principles include continuous improvement (Kaizen), maintaining a stable production schedule, and establishing strong supplier relationships to ensure timely delivery of materials. Implementing JIT requires precise demand forecasting and efficient communication channels across the supply chain to align production closely with customer demand.

Toyota: The Pioneer of JIT Implementation

Toyota revolutionized manufacturing with its Just-In-Time (JIT) system, significantly reducing inventory costs and enhancing production efficiency. By synchronizing component deliveries precisely with production schedules, Toyota minimized waste and improved cash flow. This innovative approach set a global standard, inspiring industries to adopt lean manufacturing principles worldwide.

Dell’s JIT Approach in Supply Chain Management

Dell's just-in-time (JIT) approach in supply chain management minimizes inventory costs by synchronizing component deliveries with production schedules, enabling customized PC assembly only after customer orders are received. This strategy reduces excess stock, accelerates response times, and enhances overall operational efficiency. By integrating suppliers closely and leveraging real-time data, Dell achieves cost savings and maintains a competitive advantage in the technology market.

McDonald’s Application of JIT in Food Service

McDonald's exemplifies just-in-time (JIT) inventory management by preparing food items only after receiving customer orders, minimizing waste and ensuring freshness. The company's streamlined supply chain delivers ingredients precisely when needed, reducing storage costs and enhancing operational efficiency. This application of JIT supports McDonald's rapid service model and maintains high-quality standards in a fast-paced food service environment.

Zara’s Fast Fashion and JIT Inventory Strategy

Zara's fast fashion model relies heavily on its just-in-time (JIT) inventory strategy, enabling the company to design, produce, and deliver new clothing items to stores within weeks, minimizing excess stock and reducing carrying costs. By closely integrating design, manufacturing, and logistics through real-time sales data analysis, Zara responds swiftly to market trends and customer demands. This JIT approach enhances supply chain efficiency and supports Zara's competitive advantage in the dynamic fashion retail industry.

Benefits of Adopting JIT in Modern Businesses

Implementing Just-in-Time (JIT) inventory management reduces excess stock and lowers holding costs, significantly improving cash flow in modern businesses. Enhanced production efficiency and minimized waste lead to streamlined operations and faster response to market demand, elevating overall customer satisfaction. Companies like Toyota leverage JIT to maintain lean inventory levels while ensuring timely product availability, demonstrating substantial competitive advantage.

Challenges and Risks of Just-in-Time Systems

Just-in-time (JIT) systems in business streamline inventory by minimizing stock levels and relying on precise timing for deliveries, which can lead to significant risks like supply chain disruptions and production delays. Challenges include dependency on reliable suppliers, vulnerability to demand fluctuations, and limited buffer stock increasing the impact of any logistical failures. Effective risk management requires robust communication, contingency planning, and real-time monitoring to mitigate the potential for costly downtime and lost sales.

Real-Life JIT Success Stories Across Industries

Toyota revolutionized manufacturing with its Just-in-Time (JIT) inventory system, reducing waste and improving efficiency by synchronizing production schedules with supplier deliveries. Dell Computer implemented JIT to customize products quickly, minimizing inventory costs and accelerating order fulfillment in the technology sector. Retail giant Walmart leverages JIT logistics to maintain lean stock levels while meeting consumer demand promptly, optimizing supply chain performance across its vast network.

Best Practices for Implementing JIT in Business

Effective just-in-time (JIT) implementation in business relies on maintaining strong supplier relationships to ensure timely delivery of materials, reducing inventory costs, and minimizing waste. Employing advanced inventory management software and real-time data analytics enhances demand forecasting accuracy, aligning production schedules closely with customer orders. Continuous employee training and establishing a culture of quality control support seamless JIT operations, reducing defects and improving overall efficiency.

example of just-in-time in business Infographic

samplerz.com

samplerz.com