In technology, specifically in electronics manufacturing, a whisker refers to tiny, hair-like metallic filaments that grow naturally from the surface of solder or metal components. These whiskers are composed primarily of tin or tin-lead alloys and can cause electrical short circuits by bridging adjacent conductive paths. The presence of whiskers in solder joints poses significant reliability risks in printed circuit boards (PCBs) and electronic assemblies. The phenomenon of whisker growth is influenced by factors such as mechanical stress, humidity, temperature, and the purity of the solder material. Tin whiskers can reach lengths of several millimeters and create critical failures in high-density or high-frequency electronic devices. Understanding whisker formation is essential for developing mitigation techniques like using conformal coatings, alloying additives, or alternative solder materials to ensure long-term device performance.

Table of Comparison

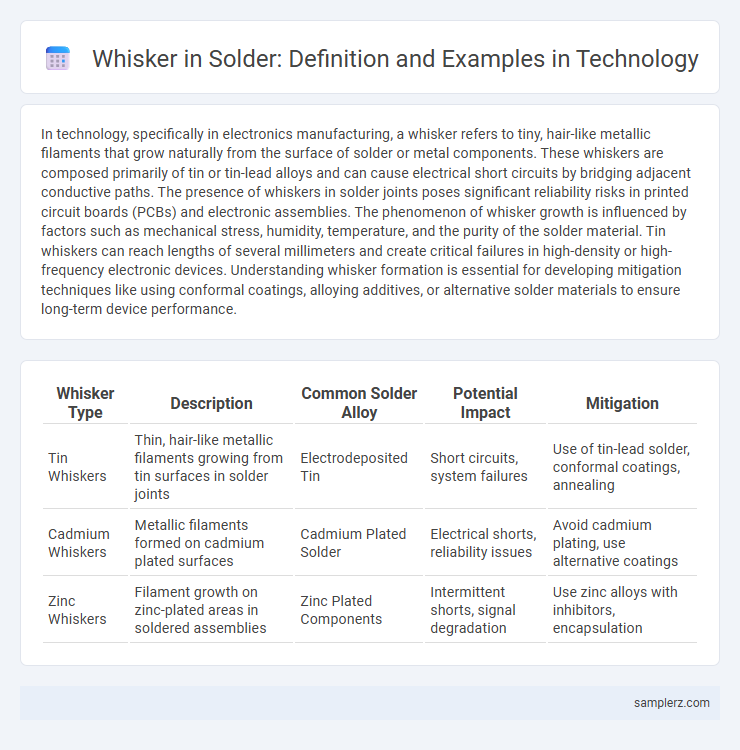

| Whisker Type | Description | Common Solder Alloy | Potential Impact | Mitigation |

|---|---|---|---|---|

| Tin Whiskers | Thin, hair-like metallic filaments growing from tin surfaces in solder joints | Electrodeposited Tin | Short circuits, system failures | Use of tin-lead solder, conformal coatings, annealing |

| Cadmium Whiskers | Metallic filaments formed on cadmium plated surfaces | Cadmium Plated Solder | Electrical shorts, reliability issues | Avoid cadmium plating, use alternative coatings |

| Zinc Whiskers | Filament growth on zinc-plated areas in soldered assemblies | Zinc Plated Components | Intermittent shorts, signal degradation | Use zinc alloys with inhibitors, encapsulation |

Understanding Solder Whiskers: Definition and Significance

Solder whiskers are microscopic, hair-like metallic filaments that spontaneously grow from solder surfaces, often composed of tin or tin-based alloys. These whiskers pose significant risks in electronic devices, causing short circuits and reliability failures due to their ability to bridge conductive paths. Understanding the formation mechanisms and mitigation techniques of solder whiskers is crucial for enhancing the durability and performance of semiconductor packaging and electronic assemblies.

Common Causes of Whisker Formation in Solder Joints

Whisker formation in solder joints is commonly triggered by mechanical stress, electrochemical migration, and thermal cycling, which induce metal atom diffusion and crystal growth. Lead-free solder alloys, particularly those containing tin, are more susceptible to whiskering due to their grain structure and residual stress levels. Understanding these causes is crucial for improving reliability in electronic assemblies and preventing short circuits or device failures.

Real-world Examples of Solder Whisker Growth in Electronics

Solder whisker growth has been observed in high-reliability electronics such as aerospace control systems and medical devices, where tin used in lead-free solders spontaneously forms tiny, hair-like filaments that risk short circuits. Notable cases include NASA's spacecraft electronics experiencing intermittent failures attributed to tin whiskers causing electrical shorts. Effective mitigation strategies involve conformal coatings and alloying with metals like bismuth or nickel to inhibit whisker formation and ensure long-term device reliability.

Tin Whiskers vs. Solder Whiskers: Key Differences

Tin whiskers are tiny, hair-like metallic filaments that spontaneously grow from pure tin surfaces, causing short circuits in electronic solder joints. Solder whiskers, in contrast, typically form due to mechanical stress or thermal cycling in mixed metal solder alloys, often containing lead, silver, or copper. The primary difference lies in their growth mechanisms and materials involved, with tin whiskers posing higher risks in lead-free solder applications used in modern electronics.

High-profile Failures Linked to Solder Whisker Example Cases

High-profile failures linked to solder whiskers include the 2003 Intel Pentium 4 server crash, where tin whiskers caused short circuits on the motherboard. Another notable case is the 2010 aerospace incident involving NASA's Mars Rover, where solder whiskers contributed to critical component malfunctions. These examples highlight the risk solder whiskers pose in high-reliability technology applications, emphasizing the need for advanced mitigation strategies.

Case Study: Solder Whisker Issues in Aerospace Systems

Solder whiskers are microscopic, hair-like metallic filaments that grow from solder joints and pose reliability risks in aerospace electronic systems due to potential short circuits and signal interference. A notable case study involves the examination of whisker-induced failures in satellite control units, where tin whiskers caused intermittent electrical shorts leading to critical system malfunctions during mission operations. Mitigation strategies such as conformal coatings, whisker-resistant solder alloys, and rigorous environmental testing have been implemented to enhance the durability of aerospace electronics against solder whisker growth.

Solder Whisker Formation in Consumer Electronics: Examples and Impacts

Solder whiskers commonly form in consumer electronics such as smartphones and laptops due to tin or tin-lead solder layers under mechanical stress or thermal cycling. These microscopic, hair-like metallic filaments can cause short circuits and device failures by bridging closely spaced components on circuit boards. Understanding solder whisker formation aids manufacturers in improving reliability through material selection and protective coatings.

Mitigation Methods: Preventing Solder Whisker Growth

Mitigation methods for preventing solder whisker growth focus on using conformal coatings, employing proper annealing processes, and selecting appropriate alloy compositions such as tin-silver-copper (SAC) instead of pure tin. Implementing underlayer barriers like nickel or copper plating helps inhibit whisker formation by reducing internal stresses. Regular inspections combined with environmental controls, such as humidity and temperature regulation, further minimize the risk of solder whisker-induced failures in electronic assemblies.

Solder Whisker Analysis Using Microscopy: Practical Examples

Solder whiskers are microscopic, hair-like metallic growths that can cause short circuits and failures in electronic assemblies. Practical examples of solder whisker analysis using microscopy involve scanning electron microscopy (SEM) to observe whisker morphology and growth patterns on tin-lead or lead-free solder surfaces. Energy-dispersive X-ray spectroscopy (EDX) complements this analysis by identifying the elemental composition of whiskers, enabling engineers to understand whisker formation mechanisms and develop mitigation strategies.

Industry Standards for Managing Whisker Risks in Solder Assemblies

Whiskers in solder assemblies, tiny metallic filaments that can cause short circuits, are managed under stringent industry standards such as IPC-9701 and JEDEC JESD22-A121. These standards provide guidelines for detecting, testing, and mitigating whisker growth, ensuring reliability and safety in electronic manufacturing. Compliance with these protocols helps manufacturers reduce the risk of failure in high-reliability applications like aerospace and automotive electronics.

example of whisker in solder Infographic

samplerz.com

samplerz.com