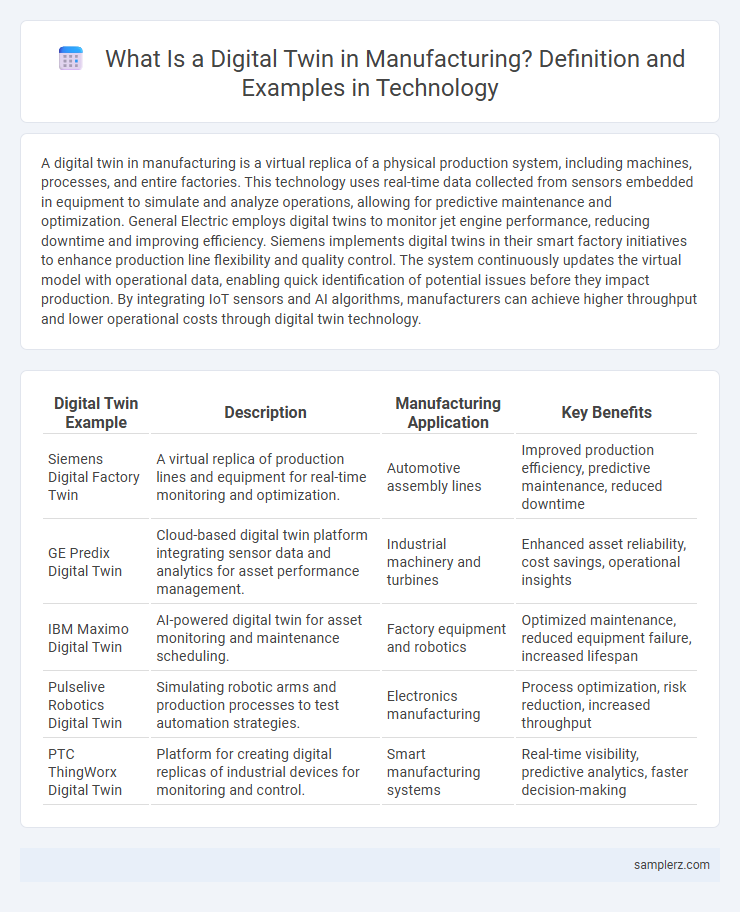

A digital twin in manufacturing is a virtual replica of a physical production system, including machines, processes, and entire factories. This technology uses real-time data collected from sensors embedded in equipment to simulate and analyze operations, allowing for predictive maintenance and optimization. General Electric employs digital twins to monitor jet engine performance, reducing downtime and improving efficiency. Siemens implements digital twins in their smart factory initiatives to enhance production line flexibility and quality control. The system continuously updates the virtual model with operational data, enabling quick identification of potential issues before they impact production. By integrating IoT sensors and AI algorithms, manufacturers can achieve higher throughput and lower operational costs through digital twin technology.

Table of Comparison

| Digital Twin Example | Description | Manufacturing Application | Key Benefits |

|---|---|---|---|

| Siemens Digital Factory Twin | A virtual replica of production lines and equipment for real-time monitoring and optimization. | Automotive assembly lines | Improved production efficiency, predictive maintenance, reduced downtime |

| GE Predix Digital Twin | Cloud-based digital twin platform integrating sensor data and analytics for asset performance management. | Industrial machinery and turbines | Enhanced asset reliability, cost savings, operational insights |

| IBM Maximo Digital Twin | AI-powered digital twin for asset monitoring and maintenance scheduling. | Factory equipment and robotics | Optimized maintenance, reduced equipment failure, increased lifespan |

| Pulselive Robotics Digital Twin | Simulating robotic arms and production processes to test automation strategies. | Electronics manufacturing | Process optimization, risk reduction, increased throughput |

| PTC ThingWorx Digital Twin | Platform for creating digital replicas of industrial devices for monitoring and control. | Smart manufacturing systems | Real-time visibility, predictive analytics, faster decision-making |

Introduction to Digital Twin Technology in Manufacturing

Digital twin technology in manufacturing creates virtual replicas of physical assets, enabling real-time monitoring and analysis of production processes. These digital models enhance predictive maintenance, optimize supply chains, and improve product design by simulating performance and identifying potential issues before they occur. Companies like Siemens and General Electric utilize digital twins to increase operational efficiency, reduce downtime, and drive innovation in smart factories.

Real-World Digital Twin Applications on Factory Floors

Digital twins in manufacturing enable real-time monitoring and predictive maintenance by creating accurate virtual replicas of factory floors. Siemens uses digital twins to simulate production processes, optimizing assembly lines and reducing downtime. GE's Predix platform leverages digital twins to analyze equipment performance, enhancing operational efficiency and minimizing costs.

Digital Twin Use in Predictive Maintenance

Digital twin technology in manufacturing enables real-time monitoring and simulation of physical assets, enhancing predictive maintenance by identifying equipment faults before failures occur. By integrating IoT sensors with AI analytics, manufacturers can anticipate machine wear and schedule maintenance proactively, reducing downtime and operational costs. This digital replica of machinery improves asset lifecycle management and supports data-driven decision-making for optimized production efficiency.

Enhancing Production Efficiency with Digital Twins

Digital twins in manufacturing create virtual replicas of physical assets, enabling real-time monitoring and predictive maintenance to reduce downtime. By analyzing data from sensors embedded in machinery, manufacturers can optimize production processes and identify inefficiencies before they cause disruptions. This technology enhances production efficiency by improving asset utilization, minimizing operational costs, and accelerating decision-making through data-driven insights.

Quality Control Optimization via Digital Twin Modeling

Digital twin technology in manufacturing enables precise quality control optimization by creating real-time virtual replicas of production lines that simulate and predict defects. This advanced modeling allows manufacturers to identify process inefficiencies and adjust parameters before physical errors occur, reducing waste and improving product consistency. Companies leveraging digital twin systems report up to 30% enhancement in quality assurance metrics and faster detection of anomalies during production cycles.

Supply Chain Visibility through Digital Twins

Digital twins enhance supply chain visibility in manufacturing by creating real-time virtual replicas of physical assets, processes, and systems. This technology enables continuous monitoring of inventory levels, production status, and logistics, leading to improved demand forecasting and risk management. Companies leveraging digital twins achieve greater transparency, operational efficiency, and responsiveness to supply chain disruptions.

Smart Factory Automation with Digital Twins

Smart factory automation leverages digital twins to create virtual replicas of physical manufacturing systems, enabling real-time monitoring and predictive maintenance. Siemens uses digital twins in their factories to simulate production processes, optimize workflows, and reduce downtime through accurate data-driven insights. By integrating IoT sensors and AI algorithms, these digital twins enhance operational efficiency and support adaptive manufacturing environments.

Energy Management Improvements in Manufacturing Using Digital Twins

Digital twins in manufacturing enable real-time energy consumption monitoring and predictive maintenance, significantly reducing operational costs and downtime. By simulating energy flows and equipment performance, manufacturers optimize resource usage and enhance efficiency across production lines. Enhanced data analytics from digital twins drive sustainable energy management strategies, contributing to greener manufacturing processes.

Remote Monitoring and Troubleshooting Enabled by Digital Twins

Digital twins in manufacturing enable remote monitoring by providing real-time virtual replicas of physical assets, allowing engineers to track performance metrics and detect anomalies instantly. These digital replicas facilitate troubleshooting by simulating operational scenarios and predicting potential failures before they occur. Companies leveraging digital twins reduce downtime and maintenance costs while enhancing productivity through proactive issue resolution.

Future Trends of Digital Twin Adoption in Manufacturing

Digital twin technology in manufacturing is evolving with the integration of AI-driven analytics and real-time IoT sensor data to enhance predictive maintenance and optimize production workflows. Future trends emphasize seamless digital twin interoperability across supply chain networks, enabling adaptive manufacturing systems that respond dynamically to market demands. Advanced simulations powered by edge computing will drive sustainable manufacturing practices by minimizing energy consumption and material waste.

example of digital twin in manufacturing Infographic

samplerz.com

samplerz.com