A kill switch in a factory is an essential safety mechanism designed to immediately stop machinery during emergencies. This device cuts power to equipment, preventing accidents and minimizing damage by halting operations instantly. Factories typically install kill switches near high-risk machines such as conveyor belts, presses, and robotic arms. These switches rely on simple yet robust technology to ensure quick response times and reliability in critical situations. Data from factory safety records often highlight the effectiveness of kill switches in reducing workplace injuries and downtime. Proper maintenance and regular testing of kill switches are crucial to maintain optimal factory safety standards.

Table of Comparison

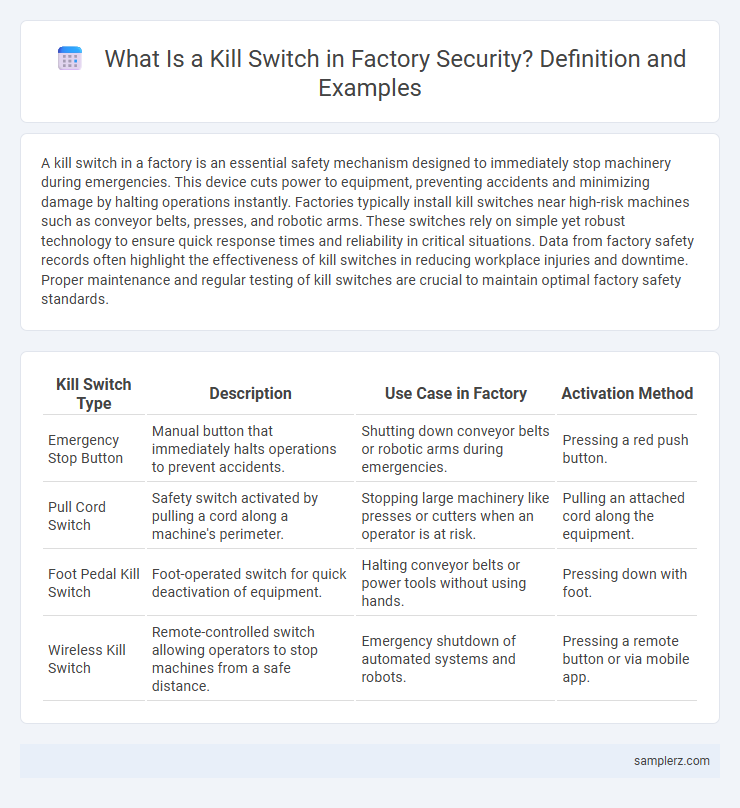

| Kill Switch Type | Description | Use Case in Factory | Activation Method |

|---|---|---|---|

| Emergency Stop Button | Manual button that immediately halts operations to prevent accidents. | Shutting down conveyor belts or robotic arms during emergencies. | Pressing a red push button. |

| Pull Cord Switch | Safety switch activated by pulling a cord along a machine's perimeter. | Stopping large machinery like presses or cutters when an operator is at risk. | Pulling an attached cord along the equipment. |

| Foot Pedal Kill Switch | Foot-operated switch for quick deactivation of equipment. | Halting conveyor belts or power tools without using hands. | Pressing down with foot. |

| Wireless Kill Switch | Remote-controlled switch allowing operators to stop machines from a safe distance. | Emergency shutdown of automated systems and robots. | Pressing a remote button or via mobile app. |

Introduction to Kill Switches in Factory Security

A kill switch in factory security is a critical safety mechanism designed to immediately halt machinery operation during emergencies, preventing accidents and equipment damage. These switches are strategically installed near control panels or hazardous zones for quick access by operators. By enabling rapid shutdown, kill switches minimize injury risks and enhance overall workplace safety compliance.

Key Functions of Kill Switches in Industrial Environments

Kill switches in industrial environments provide immediate shutdown of machinery to prevent accidents and equipment damage, enhancing workplace safety. These devices monitor operational status continuously and enable rapid response to emergencies by interrupting power supply instantly. Key functions include safeguarding personnel, minimizing hazardous incidents, and ensuring compliance with industry safety standards.

Real-World Examples of Factory Kill Switch Deployment

In manufacturing plants, kill switches are strategically installed on assembly lines to immediately halt machinery during emergencies, preventing accidents and equipment damage. Automotive factories use kill switches integrated with robotic arms to stop operations when sensors detect malfunctions or safety breaches, ensuring worker safety. Chemical production facilities deploy kill switches connected to control panels, enabling rapid shutdown of hazardous processes to contain spills or fires effectively.

Emergency Power-Off (EPO) Systems in Manufacturing

Emergency Power-Off (EPO) systems in manufacturing serve as critical kill switches that instantly cut electrical power to machinery in case of emergencies, preventing accidents and equipment damage. These systems are integrated into factory safety protocols, enabling operators to halt production lines swiftly during hazardous events such as electrical faults, fires, or mechanical failures. EPO installations comply with industry standards like IEC 60204-1, ensuring reliable rapid shutdown to safeguard personnel and maintain operational safety.

Kill Switch Integration with Automated Machinery

Kill switch integration with automated machinery enhances factory safety by providing an immediate shutdown mechanism during emergencies, preventing equipment damage and worker injury. These systems are embedded in control panels or connected via IoT networks to monitor critical parameters and trigger rapid power cutoffs when anomalies are detected. By combining kill switches with automated monitoring, factories achieve real-time risk mitigation and operational continuity.

Case Study: Kill Switch Use in Assembly Lines

Case Study: Kill Switch Use in Assembly Lines demonstrates how emergency stop mechanisms enhance worker safety and prevent equipment damage by instantly halting machinery during hazardous situations. In automotive manufacturing plants, strategically placed kill switches reduce accident rates by enabling rapid response to mechanical failures or operator errors. Data shows that implementing kill switches correlates with a 40% decrease in workplace injuries and significantly lowers downtime caused by malfunctioning assembly line equipment.

Kill Switches in Hazardous Material Handling

Kill switches in hazardous material handling factories rapidly isolate power or machinery to prevent chemical spills, fires, or explosions, ensuring worker safety and environmental protection. These emergency controls are strategically installed on equipment like conveyor belts, mixers, and storage tanks containing flammable or toxic substances. Automated sensor-triggered kill switches enhance hazard response by immediately halting operations at the detection of leaks, temperature spikes, or pressure anomalies.

Remote Kill Switch Activation for Factory Security

Remote Kill Switch Activation in factory security enables immediate shutdown of critical machinery to prevent accidents or unauthorized operations during emergencies. This system integrates IoT sensors and secure communication protocols to trigger equipment stop commands remotely, minimizing downtime and enhancing worker safety. Factories employing remote kill switches experience faster response times to hazards, reducing potential damage and operational risks.

Safety Protocols Involving Kill Switch Operations

Kill switch operations in factory safety protocols are designed to immediately halt machinery to prevent accidents or equipment damage during emergencies. These systems often integrate with emergency stop buttons placed strategically on production lines, enabling rapid shutdown of hazardous processes. Regular testing and employee training on kill switch usage are critical components to ensure swift response and maintain workplace safety compliance.

Future Trends: Smart Kill Switches in Industry 4.0

Smart kill switches in Industry 4.0 integrate IoT sensors and AI algorithms to provide real-time monitoring and predictive shutdown capabilities, enhancing factory safety and reducing downtime. These intelligent systems enable automated response to hazardous conditions by analyzing data from connected devices, minimizing human intervention and error. The adoption of smart kill switches accelerates the transition towards fully automated and resilient industrial operations within smart factories.

example of kill switch in factory Infographic

samplerz.com

samplerz.com