A borescope is an essential tool in cargo security inspections, allowing operators to visually examine inaccessible areas within containers and vehicles. This device consists of a flexible or rigid tube equipped with a camera and light source, transmitting real-time images to a display screen. Cargo inspectors use borescopes to detect contraband, structural damage, and hidden compartments without opening the container. Data collected from borescope inspections enhance the accuracy of security audits and compliance reporting. High-resolution imaging capability supports the identification of suspicious materials or tampering signs, improving threat detection efficiency. The integration of borescope technology with other scanning systems strengthens overall cargo security protocols at ports and border crossings.

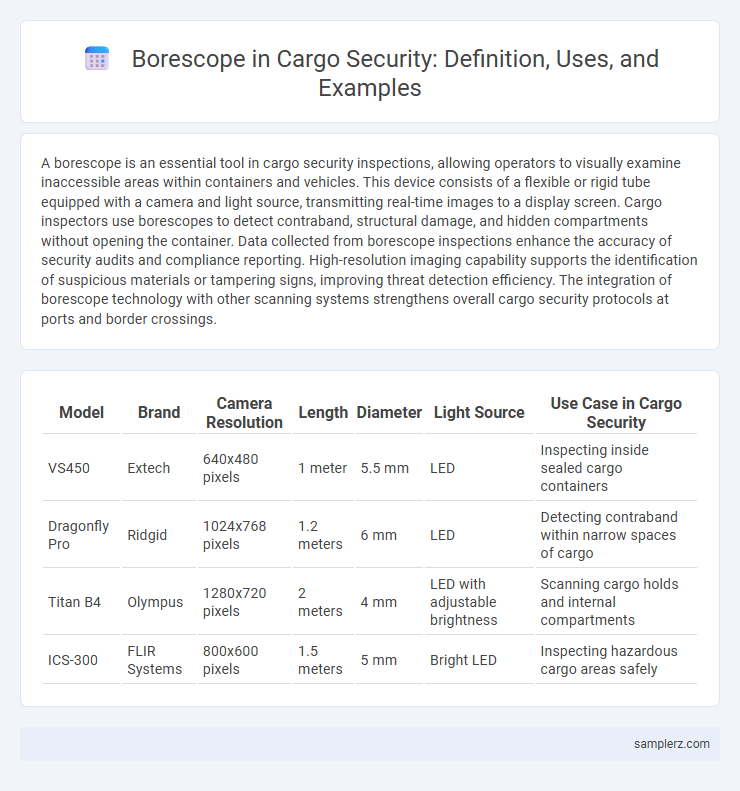

Table of Comparison

| Model | Brand | Camera Resolution | Length | Diameter | Light Source | Use Case in Cargo Security |

|---|---|---|---|---|---|---|

| VS450 | Extech | 640x480 pixels | 1 meter | 5.5 mm | LED | Inspecting inside sealed cargo containers |

| Dragonfly Pro | Ridgid | 1024x768 pixels | 1.2 meters | 6 mm | LED | Detecting contraband within narrow spaces of cargo |

| Titan B4 | Olympus | 1280x720 pixels | 2 meters | 4 mm | LED with adjustable brightness | Scanning cargo holds and internal compartments |

| ICS-300 | FLIR Systems | 800x600 pixels | 1.5 meters | 5 mm | Bright LED | Inspecting hazardous cargo areas safely |

Introduction to Borescopes in Cargo Security

Borescopes enhance cargo security by providing detailed internal inspections without unpacking shipments, enabling detection of hidden contraband, structural damages, or unauthorized modifications. These optical instruments utilize fiber optics or digital cameras to navigate narrow spaces within cargo containers, offering real-time visual access in hard-to-reach areas. Implementing borescopes streamlines security checks and reduces inspection times while maintaining high accuracy in threat identification.

Key Applications of Borescopes in Cargo Inspections

Borescopes play a crucial role in cargo inspections by enabling detailed internal examination of containers without the need for unpacking, significantly enhancing security checks for contraband or hazardous materials. They are used to inspect tight spaces, hidden compartments, and sealed containers, ensuring compliance with safety regulations and preventing smuggling or tampering. This technology improves accuracy and efficiency in identifying potential threats, reducing inspection times while maintaining thoroughness.

Types of Borescopes Used for Cargo Examination

Fiber optic and video borescopes are commonly used for cargo examination due to their ability to navigate tight and hard-to-reach spaces within shipping containers and vehicles. Rigid borescopes provide high-resolution imaging for inspecting smaller openings or compartments, while flexible borescopes offer versatility in maneuvering around corners and irregular surfaces. These types of borescopes enable detailed visual inspection, aiding in the detection of contraband, hidden compartments, and security threats during cargo screening processes.

Detecting Contraband: Borescope Success Stories

Borescopes have proven invaluable in detecting contraband within cargo shipments, enabling security personnel to inspect hard-to-reach areas without dismantling containers. In numerous cases, borescope inspections uncovered hidden compartments concealing illegal drugs, weapons, and counterfeit goods, preventing large-scale smuggling operations. This non-invasive technology significantly enhances cargo security by providing detailed visual evidence and accelerating threat identification during customs inspections.

Borescope Guidelines for Safe Cargo Screening

Borescopes provide a critical tool for non-invasive inspection of cargo containers, enabling security personnel to detect hidden contraband or hazardous materials without opening the container. Effective borescope guidelines recommend thorough visual checks of container seals and internal compartments, adherence to calibration standards for image clarity, and use of high-resolution optics for precise anomaly identification. Proper training in borescope operation and maintenance ensures accurate screening results, reducing the risk of cargo tampering and enhancing overall port security.

Enhancing Border Security with Borescopic Tools

Borescopic tools enable detailed inspection of cargo containers at border checkpoints, allowing security personnel to detect hidden contraband and unauthorized compartments without unloading shipments. High-resolution, flexible borescopes provide real-time imaging inside sealed cargo, improving threat identification and reducing inspection time. Integrating borescopes into border security protocols enhances overall efficiency and helps prevent smuggling and trafficking activities.

Case Study: Borescope Detection of Hidden Threats in Shipments

Borescopes have proven invaluable in security inspections, enabling detailed internal examination of cargo containers without unpacking. In a notable case study, customs officials used borescope technology to uncover hidden compartments containing illicit substances concealed within machinery parts. This non-invasive detection method enhances threat identification accuracy and expedites the inspection process, significantly improving shipment security.

Challenges and Limitations in Borescope Cargo Inspection

Borescope cargo inspection faces challenges such as limited field of view and difficulty accessing tightly packed or irregularly shaped cargo compartments, which can lead to incomplete assessments. Image quality degradation in low-light or cluttered environments reduces the accuracy of defect or contraband detection. Furthermore, reliance on operator expertise and the potential for mechanical failure limit the overall efficiency and reliability of borescope inspections in complex cargo security operations.

Integrating Borescopes with Other Security Technologies

Integrating borescopes with advanced X-ray scanning and AI-driven image analysis enhances cargo inspection accuracy by enabling detailed visual access to concealed compartments. Combining borescope footage with real-time sensor data improves threat detection and reduces manual inspection time, increasing overall security efficiency. This multi-technology approach supports compliance with international cargo screening standards and mitigates risks of smuggling or hazardous materials.

Future Trends: Advancements in Borescope Usage for Cargo Security

Future trends in borescope technology for cargo security include enhanced imaging capabilities such as 4K resolution and 3D visualization, which enable more precise inspection of containers and concealed compartments. Integration of AI-powered anomaly detection algorithms improves the identification of suspicious objects and contraband, minimizing human error and increasing scanning efficiency. Wireless and compact borescopes facilitate real-time remote monitoring, streamlining cargo inspections at ports and border checkpoints while enhancing overall supply chain security.

example of borescope in cargo Infographic

samplerz.com

samplerz.com